Vol. 39 (# 09) Year 2018. Page 28

Tatiana V. MALYSHEVA 1; Alexey I. SHINKEVICH 2; Leonid M. OSTANIN 3; Larisa F. ZHANDAROVA 4; Tatyana V. MUZHZHAVLEVA 5; Elena A. KANDRASHINA 6

Received: 08/01/2018 • Approved: 15/01/2018

ABSTRACT: The purpose of this paper is a synthesis of business processes logistic support's modern methods the introduction of which into the production organization practice will improve the efficiency of logistics service and thereby increase the competitiveness of petrochemical products. The leading method to the study of this problem is a systemic economic analysis method, allowing identifying the entity, regularities, and trends of occurring processes at all levels of petrochemical products lifecycle management. To assess the sustainability of production and the nature of enterprises organizational-technical development the analysis methods are encouraged to use, based on the profitability assessment of added value, which demonstrates the ability of enterprises to self-sufficiency for competitive development. |

RESUMEN: El objetivo del artículo es generalizar los métodos modernos de apoyo logístico de los procesos comerciales, cuya introducción en la organización de la producción permitirá mejorar la eficacia de los servicios logísticos y, por lo tanto, aumentar el nivel de la competitividad de los productos petroquímicos. El método principal para investigar este problema es el de análisis económico del sistema que permite identificar la esencia, las regularidades y las tendencias de los procesos que ocurren en todos los niveles de la gestión del ciclo de vida de los productos petroquímicos. Para evaluar la sostenibilidad de la producción y la naturaleza del desarrollo organizacional y tecnológico de las empresas se propone utilizar métodos de análisis basados en la evaluación de la rentabilidad del valor agregado que demuestra la capacidad de las empresas para la autosuficiencia con fines del desarrollo competitivo. |

In the competitive environment changes a reorientation of production activities is needed to the needs of the market, which provides the transition to the process approach in the enterprise management and attracting advanced techniques and models in production and management processes. The use of modern tools of production organization and business process management ensures competitiveness of enterprises in a global business environment.

In the practice of domestic industrial enterprises, to date, there has not been a single mechanism for logistical support of production to improve its efficiency. The lack of effective management tools leads to unsuccessful attempts to adapt foreign methods and models to domestic conditions.

One of the tendencies of the modern global economy is the change of priorities for the development of enterprises, when information becomes the most valuable commodity, information technology becomes the basic tool of professional human activity, and intellectual capital becomes the main economic asset. In these circumstances, it becomes necessary to activate the innovative potential of enterprises and to orientate production activities to market needs, which involves a transition to a process approach in management and the involvement of advanced methods and models in the production and management processes. The use of modern business process management tools ensures the competitiveness of enterprises in the global business environment.

The theoretical basis of the process approach to the management of logistics business processes is formed by works of A.E. Brom (2015), G.A. Ganeeva (2014), E.A. Eremina (2008), O.A. Kurnosova-Yurkova (2013), A.I. Shinkevich (2016), etc. Separate aspects of theory and practice regarding the reengineering of business processes and the production competitiveness are considered by domestic and foreign scientists, such as K.R. Gonchar (2008), E.N. Ryabinina (2016), Т.V. Malysheva (2014), V.P. Kandilov (2012), A.M. Kireenko (2010), V.V. Krivorotov (2005), A.V. Nikolaev (2015), M. Porter (2004), F.M. Ulmasov (2009) and others.

At the same time, up to now there has not been created a single mechanism for managing the logistical business processes of enterprises to improve their efficiency in modern conditions. The lack of effective management tools leads to unsuccessful attempts to adapt foreign methods and models to domestic conditions. However, most projects of companies’ organizational and economic development do not lead to the planned goals, since they do not take into account the specifics of doing business.

However, there are very few scientific and applied works devoted to the study of competitive petrochemical products' production organization, and the available works are only of a theoretical discussion nature. The aspect we examined was not considered in previous works. The problems mentioned above cause the urgency of this direction.

The scientific paper purpose is to generalize modern methods of business processes logistical support, the introduction of which into the organization of production will improve the effectiveness of logistics services and thereby improve the competitiveness of petrochemical products.

The assessment of production competitiveness efficiency is a separate, rather diverse field of economic knowledge by the types of approaches and methods used. The methodology for assessing the sustainability of production has a significant potential for further research and development on this basis of optimal management solutions to improve product competitiveness.

The study of organizational structures of product life cycle management is a complex interrelated process of researching the structure and content of the management cycle, the organization of managerial work, information, technical and mathematical support, the composition of bodies and management costs.

The theory and practice of implementing actions to improve the competitiveness of production have a variety of methods and practical tools for assessing real projects. In our opinion, as an indicator of enterprises sustainability that testifies to its competitive position in the market, it is expedient to use the profitability index of the company's added value (RAV), defined as the share of production profit in added value:

The high value of this parameter indicates a favorable financial position of the organization, which may indicate the efficiency of the enterprise, its relative competitiveness in the product market. The presence of free profits means the availability of reserves to increase competitiveness, the ability of the enterprise to further development at the expense of its own resources. On the contrary, the low level of profitability of added value indicates a lack of self-sufficiency, which is probably due to the unfavorable situation on the company's sales markets, high level of competition, which these organizations cannot withstand.

The purpose of the proposed technique is to provide analysts and managers of various levels with an effective tool for comparative analysis of production sustainability to changes in external conditions in order to assess the potential for increasing the competitiveness of products. The proposed technique will complement existing methods, which, in complex, will provide the necessary mechanism for a comprehensive analysis of production efficiency and for reserves identify for their further development.

The object of the study is an array of the petrochemical complex enterprises of Tatarstan Republic, possessing different levels of economic stability and the ability to self-sufficiency in competitive development.

The study of petrochemical industries stability is based on official regulatory documents and materials on the production of value added by enterprises of Tatarstan Republic. Within the framework of statistical reporting, information is generated on the volumes and dynamics of output, on the production of added value, on the formation of production profits, on the structure of costs and on their effectiveness.

The study includes the following stages:

the application substantiation of the matrix flow structure to control the production of petrochemical products;

systematization of logistical support’s modern methods of petrochemical products life cycle; analysis of the stability of the petrochemical complex enterprises and assessment of the need for business process reengineering;

the problem of using information systems in the implementation of continuous information support concept for the life cycle of the product.

The functioning of any enterprise depends on the effective operation of the main production unit, the servicing units and the validity of the decisions made in the management system. Logistics is service-oriented, therefore it is considered that logistics service is inextricably linked to the process of distribution and is a set of services provided by the manufacturer or a third-party company in the process of delivering resources and products to the consumer. At the same time, the process of production is also accompanied by a number of services that are present throughout the value chain of cost formation and are economically productive. They ensure the entry of material, financial and information flows into the production and economic system, the passage inside and exit from the system: transportation and repair services, communications, information, supply and marketing services, consulting and services. Consequently, the logistics service is present at all stages of the industrial enterprise's activities and is aimed at servicing the production in order to satisfy the final consumers in the given quantity of products, at the necessary time, in the right place. The transition to a process approach also changes the methodology of managing logistics services as an interrelated chain of business processes, under which we understand a mutually determined and interdependent set of an enterprise logistic activity types, the successive implementation of which is aimed at converting "enter" into "exits" in order to obtain a result of value for consumer (Kurnosova-Yurkova, 2013).

Strategic importance in terms of effective implementation of the organization functional purpose belongs to its organizational structure. The projecting of the management system organizational structure depends both on a number of external factors (the position of the enterprise in the marketing channel system, the degree of its dependence on general suppliers, the requirements of regional suppliers and consumers of the enterprise's products, etc.), and on the internal features of the production process (intra-production factors) and management systems (managerial factors).

The influence of these factors on the organizational structure occurs as a result of their impact on the characteristics of the control object and, as a consequence, on the objectives and functions of the control system. By influencing the production process (its specialization, type of production, structure, parameters, etc.), these factors change the characteristics of the enterprise and its elements, the objectives and functions of the management system, the degree of work automation, the activities of management personnel. This allows you to choose the optimal type of organizational management structure and its quantitative characteristics for optimal conditions: the scope of work to perform the management functions, their distribution according to hierarchy levels, the composition and number of personnel by departments, and the interrelationships between the management system's divisions (Malysheva & Ganeeva, 2014).

In the theory of constructing organizational structures, linear links (administrative subordination), functional links (in the field of activity without direct administrative subordination), inter-functional, or cooperative ties (between units of the same level) are distinguished. Organizational structures of the linear and functional structure relate more to the bureaucratic type of organization management, which is characterized by a clearly defined list of responsibilities for each structural unit within the organization, little incentives for an individual employee to achieve goals, has a low degree of flexibility and adaptability to external changes.

In our opinion, one of the most adapted to the market conditions, to modern economic realities, as well as to the specifics of multi-level petrochemical industries is the matrix structure oriented to the product (Fig. 1). The matrix structure is a combination of two kinds of separation: by function and by product. This is a kind of the divisional structure superimposition into a functional one in the form of a matrix (lattice) consisting of cells. In accordance with the linear structure (vertically), management is organized for certain areas of the enterprise activity: R & D, production, marketing, supply. In accordance with the program-target structure (horizontally), the management of programs (projects, themes) is organized.

Figure 1

Matrix flow structure for controlling production of petrochemical products, focused on the product

The main principle of forming a matrix structure is a developed network of horizontal flows. In order to operate the production within the matrix structure, it is necessary to introduce changes in the production structure, the formation of special target units. To ensure coordination of work in the matrix structure of management, it is expedient to create effective logistical support throughout the life cycle of the product. The advantages of the matrix flow structure to control production include:

Logistic business processes belong to the class of basic (production support) and auxiliary (maintenance). Their regulation and optimization allow you to structure the management of the logistics service, determine the areas of responsibility, and allocate resources and the order of interaction between performers. The specified definition of logistics services is proposed from the viewpoint of the process approach to management. Logistics services are the result of activities in an integrated chain of basic and business-supporting enterprises, achieved in the production and marketing of products or services and aimed at meeting the needs of production, business units and end-users (Eremina, 2008). The composition and interconnection of logistics business processes predetermined the development of a modern classification of logistics services in industrial enterprises, within which the following types of functions are distinguished:

Table 1 systematizes modern methods of managing business processes of petrochemical enterprises by the types of logistics functions.

Table 1

The relationship of business process management modern types and various types of logistics functions

Types of logistic functions |

Logistic function control methods |

Intra-production |

Resource management |

Lean production |

|

Managing the balance of the production capacity of the enterprise (S & OP) |

|

Operational-Scheduling planning (OSP) |

|

System of general productive maintenance of equipment (TPM) |

|

(Computer Integrated Manufacturing Concept– CTM) |

|

(Supply Chain Management, SCM) |

|

Distributive |

Personalized marketing |

VIP sales and sales management |

|

Customer Relationship Management (CRM) |

|

Financial |

Controlling |

Budgeting |

|

Accounting |

|

(Business Performance Management – BPM) |

|

Organizational |

Business Coaching |

Benchmarking |

|

Benchlearning |

|

(Balanced Scorecard, KPIs) Key Performance Indicators |

|

Reengineering of business processes |

|

Kaizen |

|

Total Quality Management (TQM) |

|

Six Sigma |

|

Outsourcing |

|

Franchising |

|

Document management |

|

(EAM, Enterprise Asset Management) |

|

(BI – Business Intelligence) |

Any changes in the business environment - the emergence of new activities, the expansion of the range of products, the modernization of supply chains, the introduction of new production technologies, and automation of management processes - require immediate transformation of the affected business processes. This is due to the fact that the process-oriented organization of activities involves a continuous cycle of products production and ensuring quality control at each step of the logistics chain. Therefore, to maintain high efficiency of enterprises in the global business environment, their processes need optimization, continuous improvement and change (Kandilov & Malysheva, 2012). The use of appropriate management methods makes it possible to increase the validity of the decisions made while improving the logistics business processes throughout the entire life cycle of petrochemical products.

Reengineering of business processes is the most attractive among the organizational management methods for organizational logistics functions for the purpose of increasing business efficiency and product competitiveness. This management method involves radical changes in key business processes in order to achieve a significant increase in efficiency, quality and reduction of costs all types. Reengineering is associated with the reorganization of processes, the reduction in the duration of the production cycle, the transition to a horizontal organization. The management method allows you to structure the processes of delivery, release and contents of products, warehouse management, order fulfillment and invoicing. Processes that are well suited to reengineering are easier to set up, automate and integrate into the corporate information system (Kireyenko, 2010).

Reengineering of business processes is used in case of need to reorganize the enterprise: radical changes in innovative development, business restructuring, changing organizational management structures. To increase the competitiveness of products, the enterprise must constantly improve production technologies and ways of organizing business processes. Initially, the consulting is used, which is based on past experience, judgments of experts, ready-made solutions, analogies. But you can use an alternative way, which is engineering activity. Such an approach guarantees a result if the rules and methods of using the reengineering tools are complied with, it allows controlling the completeness of the proposed solutions implementation and assessing their quality.

There are three types of organizations for which reengineering are necessary (Malysheva, Kandilov & Nikolaev, 2015):

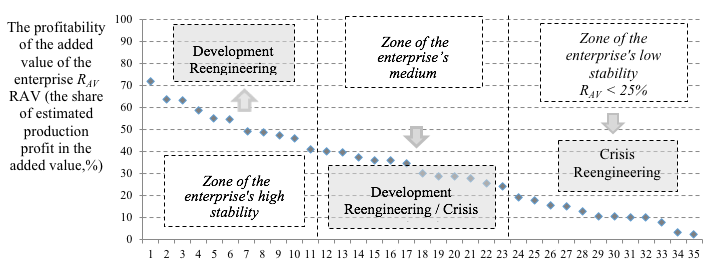

Figure 2

Distribution of the petrochemical complex enterprises of Tatarstan Republic according

to the level of sustainability and the need for reengineering business processes

Figure 2 shows the distribution of petrochemical complex enterprises of Tatarstan Republic in terms of sustainability level and the need for reengineering business processes. The study covered 35 enterprises of petrochemical industries in the Republic of Tatarstan, including companies producing crude oil and natural gas, production of petroleum products, chemical production, production of rubber and plastic products.

As a criterion for the sustainability of enterprises, the profitability index of the company's added value (RAV), defined as the share of production profit in value added, was used. The high value of this parameter indicates the favorable financial position of the organization, which may indicate the efficiency of the enterprise, its relative competitiveness in the product market (Shinkevich, Malysheva, Ryabinina, Morozova, Sokolova, Vasileva & Ishmuradova, 2016). The presence of free profits means the availability of reserves to increase competitiveness, the ability of the enterprise for further development at the expense of its own resources. On the contrary, the low level of added value profitability indicates a lack of self-sufficiency, which is probably due to the unfavorable situation on the company's sales markets, high level of competition, which these organizations cannot withstand.

The group of enterprises with high stability (RAV > 50%) included mainly enterprises producing crude oil and natural gas and large modern oil products companies. As described above, these are organizations that have no difficulties in the market, and do not anticipate them in the near future - these are leaders in their industry. In this case, for this group of enterprises the development reengineering or improvement of business processes is recommended.

The zone of enterprises’ average sustainability (50% > RAV > 25%) includes both the most successful modern companies and "novice" enterprises with an assortment of topical products on the market, produced on new high-tech equipment. For this category of enterprises will be relevant as development reengineering to maintain the dynamics and opposition to competitors, and crisis reengineering. Such restructuring is carried out after a thorough survey, revealing both the shortcomings and hidden unused capabilities of personnel, processes, information and technology, as well as after understanding new ways of their effective interaction.

The group of enterprises with low stability (RAV < 25%) includes quite large-scale petrochemical enterprises, most of them are capital-intensive associations with a high proportion of obsolete equipment, which are not flexible and do not have the ability quickly to reorient production to products in demand. To a certain extent, a solution to the current situation may be the carrying out of business processes’ crisis reengineering, namely, the creation of an integrated corporate management information system based on objective data on financial and material flows in all areas of the company's economic activities, providing overall cost reduction and flexible response on the changes in the market situation.

The principle of reengineering in application to logistics can lead to significant changes. Reengineering of logistics business processes will enable: to increase management productivity, create prerequisites for lowering the costs of the organization, improve the operational efficiency of the enterprise. One of the main reasons for the reengineering of business processes as a strategic tool is the increasing role of information technology (Shinkevich & Malysheva, 2016). The effectiveness of the implemented technological processes in the management of material flow is the main issue of logistics. Scientists and practitioners are trying to propose new methods and tools that are aimed at optimizing technological processes, the main purpose of which is to reduce the overall costs of the process, but to minimize the time for its implementation.

Currently, three main trends are clearly observed in the world market of petrochemical products: increasing the complexity and resource intensity of products, increasing competition in the market, development of cooperation between participants of the product the life cycle (including, the creation of "virtual enterprises"). In this regard, the main problem facing the domestic industry is to increase the competitiveness of manufactured products, taking into account the above trends. Achieving increased competitiveness of petrochemical products can be achieved through:

- increasing the degree of satisfaction of the customer's requirements;

- shortening the time of product creation;

- Reduction of production material costs.

The main way to increase the competitiveness of products is to increase the efficiency of its life cycle processes, i.e. increase the effectiveness of resources management used in the implementation of these processes. Currently, there are a large number of techniques designed to improve the effectiveness of various types’ resource management: material, financial, information. The key importance belongs to the speed of the reaction, which implies a high flow rate. The speed of reaction in a dynamically changing environment becomes more important than a long-term strategy. The development of the enterprise logistic system must necessarily include, according to the SCM concept, the principles of strategic interaction with suppliers, intermediaries, consumers and other participants in the process. Efficiency of the enterprise depends on achieving a controlled resonance of the logistics chain, i.e. result of streaming processes synchronization (Gonchar & Kuznetsova, 2008).

In the process of reengineering, enterprises should carry out cardinal reform in the sphere of management, relying on high-tech strategies for organizing modern business. Such a strategy, currently accepted as an international standard, is CALS (Continuous Acquisition and Life Cycle Support) - continuous information support for the product life cycle. This is a strategy to increase the efficiency, productivity and profitability of business processes through the introduction of information interaction modern methods.

The purpose of CALS-technologies’ using as an instrument of organization and information support for all participants in creation and production is to increase the efficiency of their activities by accelerating the processes of research and development of products, reducing costs in the production and operation of products, improving the level of service in its operation and technical service. The subject of CALS is technologies of information integration or sharing and exchange of information about the product, environment and processes performed during the life cycle of the product (Brom, 2015).

The basis of CALS is the use of unified information models’ set, the standardization of ways to access information and its correct interpretation, the use of automated software systems (CAD / CAM / CAE, MRP / ERP, PDM, etc.) at various stages of the life cycle, enabling the production and exchange of information in the CALS format. The availability of such a model will allow access to information about the product to all interested services of the enterprise, as well as suppliers and customers. The PLM is based on the PDM (Product Data Management) model, a product data management system developed and used, typically by engineering services.

As an example, Figure 3 shows the general relationship of information systems at different stages of petrochemical products’ life cycle.

Figure 3

Interconnection of information systems at various stages of petrochemical products’ life cycle

Any information systems, including management systems such as ERP, SCM, CRM or PLM, are used to improve the efficiency of a particular field of activity. Moreover, even a conditionally generalized enumeration of the control loops where these systems are applied can show that ERP, CRM and SCM systems increase efficiency in certain areas of their target orientation and do not have a direct impact on the products being developed and manufactured. The directionality of PLM systems is directly produced products. It can be concluded that CRM systems manage business processes associated with the initial and final stages of the product’s life cycle - the stage of research and the stage of production. SCM systems manage business processes located in the middle of the product’s life cycle - the stage of production preparation and the stage of production. ERP systems manage business processes related to the stages of development, production preparation and products’ production. And only PLM systems manage business processes associated with all stages of the product life cycle.

The following factors directly influence the economic parameters of enterprises activities using CALS-technologies:

reduction of costs and labor intensity of technical training and new products’ development processes;

shortening the time-to-market for new competitive products;

reduction of waste and costs associated with making changes in the design;

Increased sales of products supplied with electronic technical documentation, compiled in accordance with the requirements of international standards;

Reducing the costs of operation, maintenance and repair of products, which for commensurate high-tech products are commensurate with the costs of its purchase.

So, in modern conditions, increasing the competitiveness of products on the global market is not possible without the introduction of CALS-technologies. The world market will not accept products that are not equipped with electronic documentation and do not have the means of integrated logistic support of the life cycle post-production stages. To increase export-oriented domestic petrochemical products, enterprises must comply with the following requirements:

presentation of design and technological documentation in electronic form;

presentation of operational and repair documentation in the form of interactive electronic technical manuals, provided with illustrated electronic catalogs of auxiliary materials and means of their remote order;

organization of integrated logistics support of products at post-production stages of their life cycle;

availability and functioning of the electronic cataloging system;

Availability of quality management systems at the enterprises meeting the requirements of ISO 9000: 2000 standards, etc.

The fulfillment of these requirements predetermines the need for the full implementation of CALS technologies at domestic enterprises. Building a mechanism for managing logistics processes, whose goal is to promote the formation and enhancement of capacity, gaining competitive advantages in general, is one of the key problems for any system, any market. The goal of achieving the maximum effectiveness of logistics processes is to search for and select from a variety of acceptable options for optimal management actions that ensure maximum adaptation to the real conditions of a dynamic environment with limited resources.

So, during the conducted research the following theoretical and practical positions are revealed:

The matrix structure of management focused on the product is the most adapted to market conditions and modern economic realities, as well as to the specifics of multilevel petrochemical industries. It is established that in order to operate for the production within the matrix structure, it is necessary to introduce changes in the production structure, including the formation of effective logistical support throughout the life cycle of the product. Integration of the enterprise’s various activities using the matrix stream structure will allow with the least effort to adapt CALS-technologies to create continuous information support for the life cycle of the product. The introduction of information systems will allow minimizing managerial and logistical costs, reducing the administrative burden on the management by creating effective systems of logistics support of the product life cycle.

Systematization of logistical support modern methods of petrochemical products’ life cycle by types of functions has been made: intra-production, distribution, financial and organizational. It was revealed that the reengineering of business processes is the most relevant for the purpose of increasing the efficiency of the business and the competitiveness of products among the methods of managing organizational logistical functions. Based on the study of the profitability of petrochemical enterprises’ added value, the organizations were distributed according to the level of sustainability and the need for reengineering business processes. It is shown that the distribution of enterprises by the level of sustainability has a moderate relationship with the level of organizations’ technical equipment, the scale of production and the speed of business processes’ adaptation to environmental conditions. It is recommended to conduct crisis reengineering or reengineering of business processes’ development, depending on the level of the organization sustainability.

The need to improve the competitiveness of production by improving the management of product lifecycle processes or optimizing the management of resources used in the execution of business processes is indicated. In the process of organization’s reengineering it is proposed to use a high-tech strategy for the organization of modern business, based on CALS-technologies. The general interrelation of information systems at various stages of a life cycle of petrochemical production is shown. The application of PLM systems for managing a complete set of business processes associated with all stages of the product life cycle is substantiated. First-priority requirements for the introduction of CALS-technologies at domestic enterprises, providing for the availability of design and technological documentation in electronic form, organization of integrated logistics support of products at post-production stages of the life cycle are indicated..

Brom, A.E. (2015). Designing complex integrated logistical support the life cycle of high-tech products. Bulletin of the Volzhsk university named after V.N. Tatishchev, 23, 5-10.

Gonchar, K.R. & Kuznetsova, B.V. (2008). Russian industry at a growth phase: factors of competitiveness of firms. Moscow: Top.

Kandilov, V.P. & Malysheva, T.V. (2012). The competitiveness of producers in the Republic of Tatarstan and the prospects for the development of commodity markets in terms of entry into the WTO. Economic Bulletin of the Republic of Tatarstan, 4, 29-38.

Kandilov, V.P., Semenov, O.Yu. & Malysheva, T.V. (2010). Information support of indicative management of socio-economic development system of Tatarstan Republic. Statistical issues, 9, 56-60.

Kireyenko, A.M. (2010). Methodical bases of enterprise competitiveness of megalopolis. Saint-Petersburg State University of service and economics, St. Petersburg, Russia.

Krivorotov, V.V. (2005). An analytical assessment of the competitiveness of market-oriented enterprises. Regionaleconomy: theoryandpractice, 1(16), 26-33.

Kurnosova-Yurkova, O.A. (2013). The dialectics of logistics services. Messenger of Khmelnytsky National University, 2(3), 191-194.

Malysheva, T.V. & Ganeeva, G.A. (2014). Organizational and economic features of distribution logistics of petrochemical industries. Bulletin of the Kazan Technological University, 17(21), 431-434.

Malysheva, T.V. & Ganeeva, G.A. (2014). Organizational and economic peculiarities of distribution logistics petrochemical plants. Bulletin of the Kazan University, 17(21), 431-434.

Malysheva, T.V., Kandilov, V.P. & Nikolaev, A.V. (2015). Competitive products: information and analytical system «promotion of goods to foreign markets. Statistical issues, 4, 21-27.

Porter, M. (2004). International competition. Lane. with Engl. Ed. and with an introd. B. D. Shchetinina. Moscow: International Relations.

Shinkevich, A.I., Malysheva, T.V., Ryabinina, E.N., Morozova, N.V., Sokolova, G.N., Vasileva, I.A. & Ishmuradova, I.I. (2016). Formation of Network Model of Value Added Chain Based on Integration of Competitive Enterprises in Innovation-Oriented Cross-Sectorial Clusters. International Journal of Environmental and Science Education, 11(17), 10347-10364.

Shinkevich, M.V. & Malysheva, T.V. (2016). Improving the management of scientific and innovation at regional level. Herald of Belgorod University of cooperation, economics and law, 5(61), 142-151.

Territorial body of the State service of State statistics in the Republic of Tatarstan (2016). Industry in the Republic of Tatarstan. Statistical compendium. Kazan: Tatarstanstat.

Ulmasov, F.M. (2009). Improving the competitiveness of the national economy. State University of management, Moscow: Science.

Yeremina, E. A. (2008). Supply chain management: approaches, methods, models. News of Tomsk Polytechnic University, 313(6), 30-32.

1. Department of Logistics and Management, Kazan National Research Technological University, Kazan, Russia. Contact e-mail: tv_malysheva@mail.ru

2. Department of Logistics and Management, Kazan National Research Technological University, Kazan, Russia

3. Department of Chemical Equipment, Kazan National Research Technological University, Kazan, Russia

4. Higher School of Economics, Kazan National Research Technological University, Kazan, Russia

5. Department of Economic Theory and International Economic Relations, Chuvash State University named after I. N. Ulyanov, Russia, Cheboksary, Russia

6. Department of Applied Management, Samara State University of Economics, Samara, Russia