Vol. 39 (# 09) Year 2018. Page 36

Ana Alicia BOLÍVAR-LARA 1; Manuela HERNÁNDEZ 2; Antonio SERRANO 3; María José DE LA HABA 4

Received: 05/11/2017 • Approved: 14/12/2017

ABSTRACT: This study seeks to assess the complementarity of combining Lean Management tools and Near Infrared Spectroscopy (NIRS) in order to improve the efficiency and quality of services in Iberian pig slaughterhouses with a view to enhance the efficient management of hams according to genetic and feeding regimes. Lean management principles and tools (Kaizen and Value Stream Mapping) were used to apply and evaluate improvements, resulting in three different approaches as regards to improvement; i) changing the analysis method from Gas Chromatography (GC) to NIRS analysis; ii) changing the sampling methodology from batch to individual samples, and iii) suggesting the application of NIR technology for the on-line analysis of the intact fat samples. The results show a reduction in the information flow time (35%) as well as the seven typical wastes. Lead time was reduced from 61 hours to 40 hours. |

RESUMEN: Este estudio persigue evaluar la complementariedad de combinar herramientas de Lean Management y la Espectroscopia de infrarrojo cercano (NIRS) para mejorar la eficiencia y la calidad de los servicios en los mataderos de cerdo ibéricos con el objetivo de optimizar el manejo eficiente de los jamones de acuerdo con los regímenes genéticos y de alimentación de los cerdos. Se utilizaron principios y herramientas de gestión Lean (Kaizen y Value Stream Mapping) para aplicar y evaluar mejoras, resultando en tres enfoques diferentes para mejorar; i) cambiar el método de análisis de Cromatografía de gases (GC) a análisis NIRS; ii) cambiar la metodología de muestreo de un lote a muestras individuales, y iii) sugerir la aplicación de tecnología NIR para el análisis en línea de las muestras de grasa intacta. Los resultados muestran una reducción en el tiempo de flujo de información (35%) y en los siete típicos desperdicios. El tiempo de entrega se redujo de 61 horas a 40 horas. |

The food industry has been confronted with increasingly competitive pressure from the global market, and customers demand safe, high quality products. The agri-food industry has an additional level of complexity compared with other industrial processes, since there are extra physical and biological factors involved, which in turn affect the engineering process.

Iberian pig ham is one of the most expensive luxury food products produced in Europe. Major treatments are needed both before and after preparing the product, and these are tightly controlled by guidelines established by the European Union and Spanish laws.

Depending on the feeding regime during the final growth period of the animals, pigs are classified into three commercial categories (BOE, 2014): “Bellota”, “Cebo de campo” and “Cebo”.

The salting stage is a critical point in the cured ham process, and involves the extraction of water from the inside to the outside of the musculature as the salt penetrates the tissues through osmosis, causing the water to be expulsed (Ventanas 2001; Martuscelli, Lupieri, Sacchetti, Mastrocola & Pittia, 2017).

The salting stage has two main parameters: the weight of the ham and the relationship between unsaturated fatty acid and total fatty acid (FA) (Ventanas 2001; Seong et al. 2010). With knowledge of both parameters, industries can perform the salting stage correctly and thus avoid any wastage due defects caused by the growth of microorganisms and bio-enzymatic activities (Serra, Ruiz-Ramırez, Arnau & Gou, 2005; Toldrá, 2005; Flores, Aristoy, Antequera, Barat & Toldrá, 2012).

According to the official standard, Iberian pigs are classified by the percentage of fatty acid composition in the subcutaneous fat layer, as determined by gas chromatography (GC). The high costs and time-consuming analysis of melted fat by GC have prevented these quality control programs from being applied to the entire animal. Nevertheless, it is a well-known fact that the classification of individual pigs may differ greatly from the batch average (García, 2002; Serrano et al., 2012).

Previous research has identified two areas of technology which could help the quality and efficiency in the slaughterhouse: Lean Management and Near Infrared Spectroscopy (NIRS) (Khanchanapong et al., 2014, Zamora-Rojas, Pérez-Marín, De Pedro-Sanz, Guerrero-Ginel & Garrido-Varo, 2012). However, very little has been written on using both the applications together (Tanco, Santos, Rodríguez & Reich, 2013; Dora, Kumar, Van Goubergena, Molnara & Gellyncka, 2013; Khanchanapong et al., 2014).

Lean Management aims to provide goods and services which are more tailored to the needs customers at a greater speed and lower cost whilst maintaining quality, in other words, achieving more with less. In this way, the producers are able to optimize both their processes and the quality product (Abdulmalek, Rajgopal & Needy, 2006; Chen et al., 2013, Jones and Womack 2013), while also increasing production flexibility (Buehlmann & Fricke, 2016).

Lean Management focuses on waste identification and elimination by allowing only the minimum amount of processing time, lot size, production resources, material, inventory and cost (Chen et al., 2013). Different studies have shown that the use of Lean Management in the food industries is generally low and still evolving (Dora, Kumar, Van Goubergen, Molnar & Gellynck, 2014), although researchers, as well as practitioners, have called for the application of quality management practices, such as lean manufacturing, which could help the food processing industry to be more efficient and competitive by improving product quality, reducing production costs through the reduction of waste and adding value (Goncharuk, 2009; Mahalik, 2010; Mahalik and Nambiar, 2010, Kennedy, Plunkett & Haider, 2013).

The processes of ensuring food quality and safety are vital to the food industry, and the search for efficiency mainly involves developing failsafe procedures, since in most cases, failure will result in wasted food.

Achieving minimum amounts of waste in the slaughterhouse as well as the manufacturing industries is therefore a high priority currently.

One way to implement lean production is using a VSM, by mapping a productive process to identify waste, food losses, improve efficiency and productivity and reduce waste (Abdulmalek and Rajgopal, 2007, Chen et al., 2013, De Steur, Wesana, Dora, Pearce & Gellynck, 2016). VSM includes all the necessary activities to create a product and make it available to the customer, including the processes for material and information flow (Kuhlang, Edtmayr & Sihn, 2011, Jones and Womack, 2013). Kaizen meetings allow us to assess the whole process using the Lean criteria (Chen et al., 2013), and the short time needed for the analysis makes this tool especially useful in the meat industry, which is prone to a high level of variability (Simons and Taylor, 2007).

Currently, the key aspects of competitiveness aim at customer satisfaction and focus on delivery time, quality and cost (Fullerton, Cheryl & McWatters, 2001; Cuatrecasas-Arbos, Fortuny-Santos & Vintro-Sanchez, 2011). ‘Lead time’ is defined as the time required by any process to transform the inputs into outputs. It includes operating and process times as well as idle, transport and set-up times (Kuhlang et al., 2011, Jones and Womack, 2013). Processes with a minimized cycle-time mean that inefficient activities are removed from the production process, and, as a result, waste is reduced (Fullerton et al., 2001, Cuatrecasas-Arbos, 2011).

According to Wang and Cullinane (2008), a flexible Lean production system must be based on the use of technology, which provides us with information about the process. NIRS is a precise spectroscopic technique which enables us to obtain multi-attribute characterization, which in the case of hams, produces practical estimates for scientific and industrial purposes (Zamora-Rojas, Garrido-Varo, De Pedro-Sanz, Guerrero-Ginel & Pérez-Marín, 2013). The models are taken from wet tests of biological products, and, although they are prone to a degree of uncertainty as well as prediction errors, the estimated total errors (method, sampling, and others) is at the same level for GC and NIRS analysis (Zamora-Rojas et al., 2013), which means that the degree of error is acceptable.

So far, the limited application of process analytical technology in food industries has predominantly focused on non-destructive analytical instruments (Nychas, Panagou & Mohare, 2016). This paper goals to take advantage of the experience using NIRS in the food industry to evaluate potential synergies when combined with Lean manufacturing.

Previous research has shown that lead time is a critical factor when taking decisions. For instance, one recent case connected with the field of agro-industry suggested trying out strategies to jointly manage harvesting time and yield, with lead time as the main criterion to measure the efficiency of restocking (Behzadi, O'Sullivan, Olsen, Scrimgeour & Zhang, 2017).

The incorporation of NIRS technology allows us to obtain on-the-spot information about products and can be seen as just another step in the process of organizing work, which allows for innovation in the use of Lean manufacturing, a sector which requires far-reaching controls during the process.

According to the complimentary theory between manufacturing technologies and Lean practices, the combination of different resources may result in synergistic effects on operational performance (Khanchanapong et al., 2014). The difference in the results does not depend on the type or the level of advanced technology applied, but in the role of humans when using and controlling the technology and facilitating decision-making (Riezebos and Klingenberg, 2011, Abidi, Lyonnet, Chevaillier & Toscano, 2016), which is one of the key roles of management.

This paper aims to combine technologies with Lean Manufacturing tools in the Iberian pig industry, and has three main objectives: firstly, to learn about and adapt the possible use of certain Lean manufacturing tools to identify possible improvements in the slaughter line. Secondly, to evaluate the classification method in the same context (lot vs individual), the quality and the cost in order to reduce the response times for obtaining results from of classification of raw material. Third, to assess the potential synergy of using lean tool technology in a slaughterhouse, providing new tools to put into practice a Lean manufacturing management system.

The trials took place in a meat processing industry (slaughterhouse) located in Andalusia (Spain). This slaughterhouse belongs to an agricultural cooperative which is involved in a number of different industries in the livestock food product chain, including Iberian pig livestock production and meat processing.

To identify the critical points and needs of the process evaluated in this study, we used Lean Manufacturing tools such as Kaizen meetings and Value Stream Mapping (VSM) (Chen et al., 2013).

Kaizen meetings and VSM tools have been used to investigate the seven typical wastes: overproduction, waiting times, transport, inventories, over processing, motion and defects (Chen et al., 2013), while allowing effective communication and time to find ways to improve.

The Kaizen tool was applied in the slaughterhouse. During Kaizen meetings, a multidisciplinary team (slaughterhouse production, quality control, maintenance, research and development and the main receptionist from the Ham Curing Company) shared information in several weekly meetings throughout the season, following the indications of Abdulmalek et al., (2006) and Jones and Womack (2013). These meetings were focused on the process needs and generated the corresponding action plan, which ensured that the main objectives were met: improving the value chain and answering customer requirements.

VSM was carried out using the three-step method proposed by Rahani and Muhammad (2012). Firstly, a diagram was made showing the current material and information flows or Current State of how the process operates. Secondly, a Future State map was produced to identify the root causes of waste and to include improvements that could have a major impact on the process. Finally, an implementation plan was produced, highlighting the action that needed to be carried out to achieve the project aims.

Value stream mapping (VSM) produces a map of the production process and identifies strategic opportunities to improve, making it a useful, simple and powerful tool (Abdulmalek et al., 2006; Chen et al., 2013; Sihn and Pfeffer, 2013). It was used to generate a complete map of the value chain in an effort to identify the processes that would add customer value (Tanco et al., 2013).

The VSMs were carried out taking into account the average times of the workstations, which involve a number of subtasks.

To verify the features and attributes related to the quality of Iberian pig ham, GC and NIRS technologies were used. Several previous studies have shown how NIRS technology can achieve this goal (García, 2002; Pérez-Juan et al., 2010; Zamora-Rojas, et al., 2012; Serrano et al., 2012). To evaluate these proposals, we analyzed both lots and individual samples of Iberian pork fat.

A total of 553 carcasses of Iberian pigs belonging to 38 batches reared under different feeding systems on different farms in Córdoba (Spain) were analyzed to classify the product by GC and NIR.

The samples from each batch were packed and sealed in plastic bags marked with the slaughter identification code. These samples were then analyzed in an external laboratory approximately 48 hours after being collected.

Each subcutaneous adipose tissue sample was divided into 2 subsamples. The first was analyzed by NIRS in its intact form (N = 553), whereas the second one was mixed with the rest of samples belonging to animals from the same batch (N = 38).

The fatty acid profile of each mean liquid sample per batch (N = 38) was determined by gas chromatography (GC). This mean liquid sample was obtained after melting the subcutaneous adipose tissue in a microwave oven, following the methodology described by De Pedro, Casillas & Miranda (1996) and García-Olmo, Garrido-Varo & De Pedro (2009). Liquid fat samples were analyzed by GC with a capillary column to determine the fatty acid profile, as specified by the UNE-EN ISO 5508:1996. A BRUKER chromatograph equipped with 430-GC auto-sampler, a column VF-23MS (length 60 m, 0.25 mm diameter, 0.25 mm thick) and an ionization detector FID were used.

Each mean fat liquid sample per batch used for GC analysis (N = 38) was simultaneously analyzed by NIRS technology using the Multi-Purpose FT-NIR Analyzer (MPA) (Bruker Optik GmbH, Ettlingen, Germany). For the FT-NIR transmission measurements, the fat liquid samples were filled in 8 mm disposable vials. All spectra were recorded in triplicate at 40ºC after a thermal preconditioning for 10 minutes in a separate thermoblock to avoid turbid solutions. Spectra were obtained in transmission mode from 12500 to 4000 cm-1. Each spectrum was recorded as an average, based on 32 scans at a resolution of 8 cm-1.

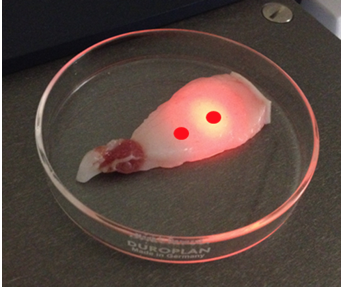

For individual samples, two different NIR analysis modes were carried out. Firstly, all the subsamples were analyzed using NIRS in their intact form. Spectra were collected using the FT-NIR MPA instrument again but with an 8 mm diameter fiber-optic contact probe (ref. IN261-2), working in interactance-reflectance mode and in the spectral region of 12500-4000 cm-1 (every 16 cm-1). Two spectral measurements were collected per sample, as shown in Fig. 1, and the average of both spectra was used for predicting the fatty acid composition.

Fig. 1

Collection of NIR spectra in intact fat samples

Secondly, each intact fat sample was melted, following the methodology described by De Pedro et al. (1996) and García-Olmo et al. (2009), and then analyzed individually in the previously described transmission mode in order to validate the results obtained from the intact fat sample analysis with the results obtained from the liquid fat sample. Finally, a ready-to-use equation was used to evaluate the fatty acid profile.

The overwhelming priority was to adapt Lean techniques to the ham production process and the most significant change generated by the process of adapting these Lean techniques to reduce waste and costs has been to simplify the objectives and focus on quality (Fig. 2).

Fig. 2

Reducing costs and waste while focusing on quality

Another change has been the incorporation of technology into the process. In this paper, we have evaluated the opportunities for incorporating technology capable of classifying and managing the raw material properly, and its potential versatility to support any future changes.

Both Lean tools (Kaizen and VSM) were applied to the slaughterhouse, which is an industry with little variety and a high volume of production. As expected, good results were achieved and extensive benefits were shown and credited to the universal application of the systems, following Abdulmalek et al. (2006). It was both possible and easy to apply Kaizen and VSM techniques in the slaughterhouse to identify and analyse potential waste issues during the process.

In the current context, customers are making growing demands on the slaughterhouse team in relation to the response time of producing the FA profile for the raw materials. The Kaizen meetings showed that information flow has to be as fast as possible in order to meet these deadlines and classify and manage the raw materials during the different salting processes. Possible waste is therefore avoided, and the efficiency of this process is increased by adjusting the cycle time (Fullerton et al., 2001).

Normally, in real production conditions, the information collected on the fatty acid profile is not incorporated into the manufacturing process in real time, but this would be a major step to satisfy customers’ needs and give added value to the product. It is also a key aspect in the use of Lean technology, as pointed out by Jones and Womack (2013) and Fullerton et al. (2001).

In the Kaizen meetings, three different sources of waste were pinpointed: the waiting time for the analytical results of the FA profile (classification), the lengthy salting period, which is sometimes unnecessarily long due to a lack of awareness of the product’s FA fraction, and the defects in the quality of the finished product due to the numbers of days spent in the salting process.

Different ways of getting faster results currently for the classification of products include improving slaughterhouse processes, especially in the dressing department, or simply applying minor changes in methods and supplier specifications.

VSM was carried out to find the specific work stations and the people involved in the information flow for classifying quality. Using this tool, each case was analysed and the differences between the current and the possible future states were assessed, according to the planned proposals. VSM was applied in the seasonal slaughterhouse in a similar way to the traditional Lean industries but taking into account the dynamic behaviour of the production processes, as recommended by some authors (Abdulmalek et al., 2006; Tanco et al., 2013).

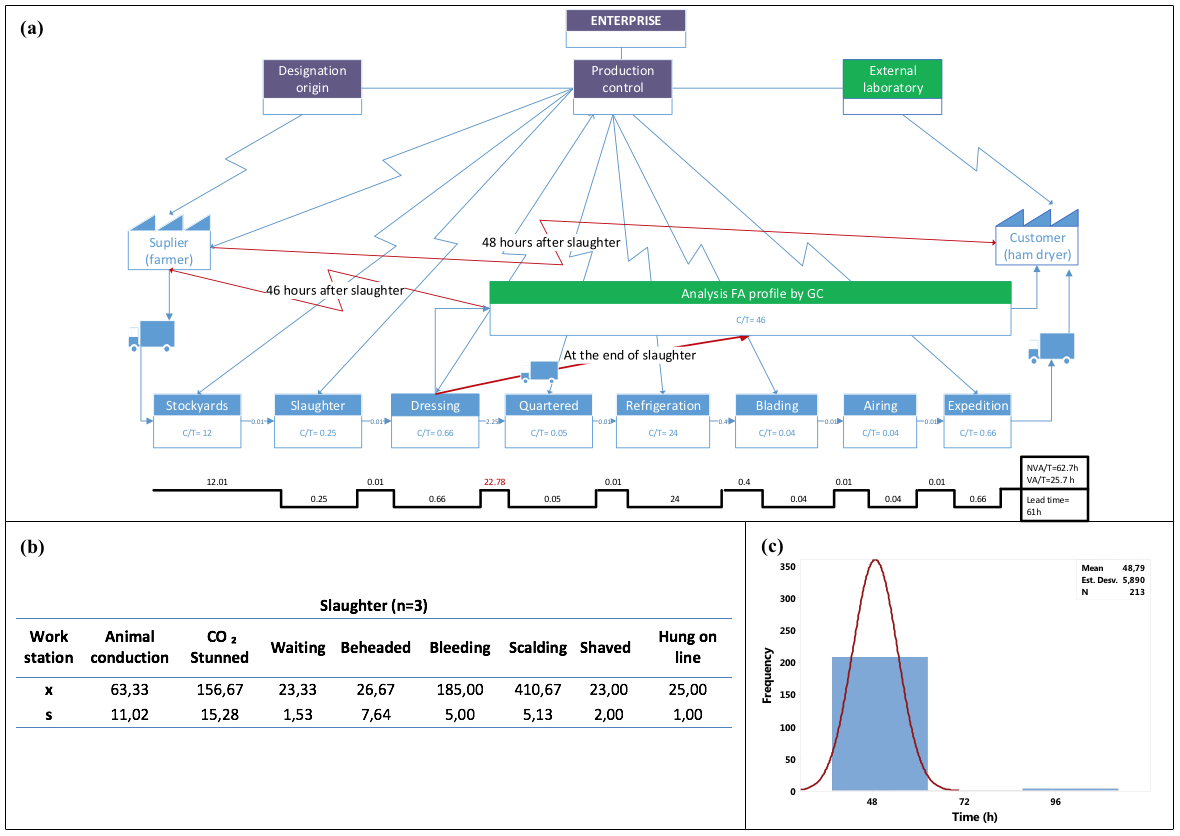

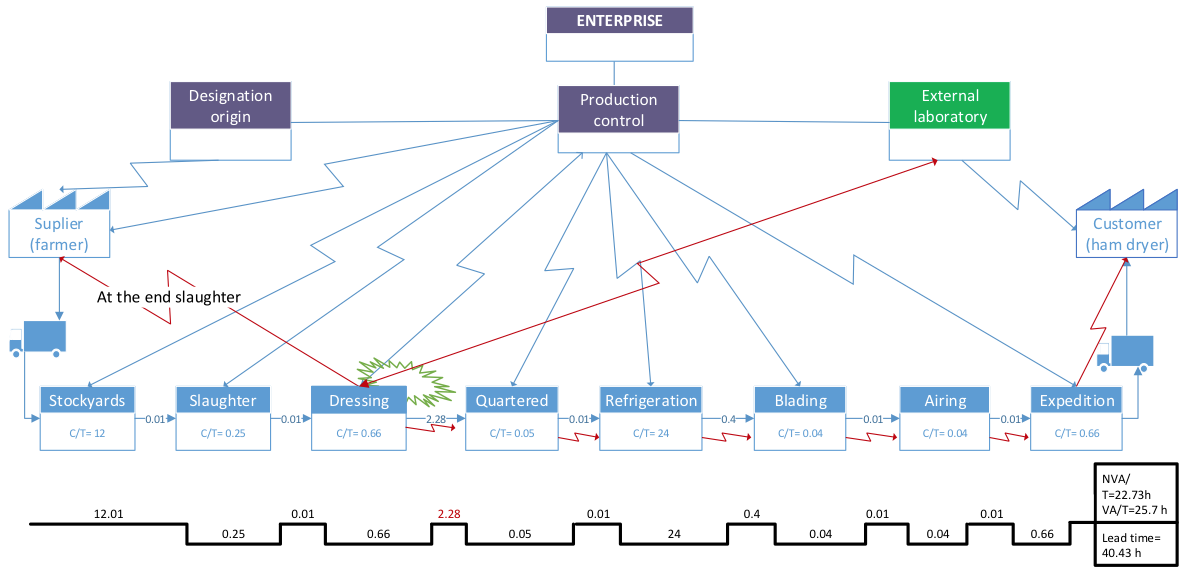

As shown in Fig. 3, in the current state, the animals come from an internal supply company which is responsible for organizing the sacrifice of batches, according to the official farm procedures. Since the slaughter line is automatic and work goes on at a constant speed of 190 carcases per hour, the most important time variations are those affecting activities which happen before the animal reaches the slaughter line. The timing of the tasks that make up the slaughtering period and how it varies are shown in Fig. 3b. The later stages have been summarized in the average data produced by the VSM – these are easily reproducible, as they now form part of the production chain.

When the animals were in the dressing department, fat samples were taken following the rules of the Iberian Pig Designation of Origin committees (BOE, 2004).

The samples were then sent to the external laboratory, and two days later, the results were obtained while the product continued with its process. This information was supported by the personal supplier, who was responsible for confirming the classification of animals, filling in documents and sending information to the ham drying rooms (the ‘customer’ in lean terms).

Twenty-four hours after the slaughter, the hams were dispatched from the slaughterhouse: this is the time when the FA profile for all the processed raw material has to be available for the ‘customers’. In the current situation, the lead time for information and material flow is 61 hours (this refers to the mean batch and not each ham).

Due to the usual variability of lead time, a frequency histogram was built on the historical data for GC analysis answer time. The results in fig. 3c show that most of the results are completed in 48 hours, some in 72 hours and others in 92 hours.

The ham curing industry needs the information about the FA profile flow in order to be ready before the slaughterhouse makes its weight classification. In this way, when hams are received by the industry, they can organize and prepare their products in batches according to the specific salting process which each individual ham requires, which depends not only on weight but also on the fat content and composition. This provides added value for customers.

The current lead time of 61 hours is therefore greater than what the customer needs. Clearly, there is room for improvement in the information flow for the FA profile from the dressing department to the customer. According to previous papers, major differences in the fatty acid profile can be found in animals belonging to the same batch, because in extensive Iberian pig production, the diet is based on natural resources available in the countryside. This may result in a lack of uniformity in the chemical composition of fat samples (Zamora-Rojas et al., 2013) as shown in animal batches using 100% analysed data, where high variability was evident.

If each category is analysed, there will be a different mean and standard deviation of the data distribution for each group: x= 48.02 and s= 1.98; x= 52.14 and s=2.31; and x= 54.77 and s= 1.60, for “Cebo”, “Cebo Campo” and “Bellota”, respectively. Each group behaves differently as regards the mean and range of the distribution, which show a high variability in samples of each category. For this reason, not only has the change in the analysis method reduced lead time, but it has also improved the individual classification of the pigs, with the result of better management in the salting operation.

This provided an opportunity to change the sampling method, since mistakes were frequently made when mean batch sampling was used to analyze the data.

As a result of the evaluation of the process and discussion at the Kaizen meetings, a change was introduced in the technique used to determine the quality classification. The best sampling method for the batches was also identified.

The information flow for quality classification and the process itself can be improved in three ways: i) by improving lead time by changing the analysis method for the melted fat samples from gas chromatography to NIR analysis; ii) by using a new sampling methodology for NIR analysis from the batch to the individual fat samples; and iii) by applying NIR technology for online analysis of the intact fat samples.

After identifying the customers requirements, the aim was to reduce lead time, since the information flow was longer than customer needs allowed using the traditional method. The laboratory team responsible for the classification analyses were asked by the slaughterhouse staff to apply a new analytical method. The technicians proposed the NIRs technique as an alternative, because experience showed that it was fast and the results were reliable. The new objective was to be more efficient when managing the information in order to optimize the salting phase in the ham production process.

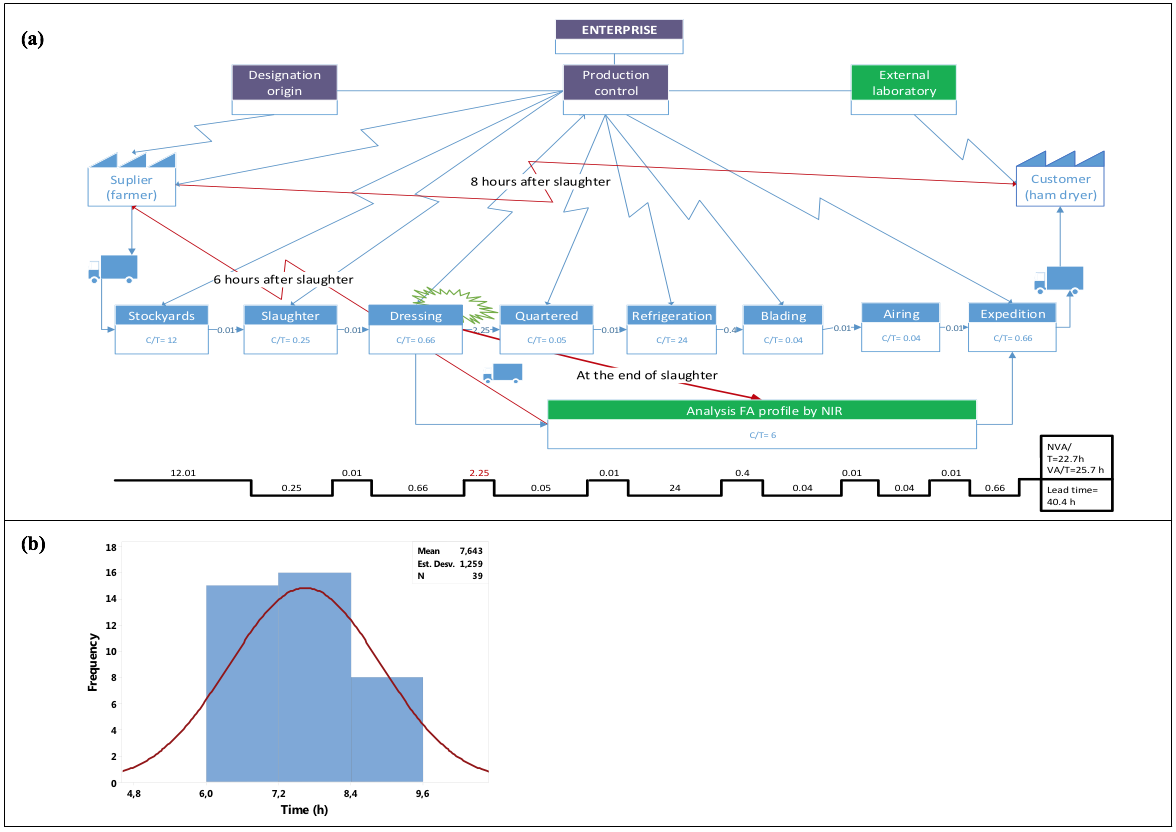

The new product process flow and map are shown in Fig. 4, and the answer time analysis is reported in a frequency histogram based on the experimental data from the NIR batch analysis (Fig. 4b). The histogram shows that the mean time for complete answer time analysis is 8 hours. Cycle time and waste for this activity would thus be reduced (Fullerton et al., 2001).

This improvement involved simply changing the analysis method by using NIRS analysis to process each batch sample. However, the analysis of each batch sample by NIRS meant that samples were made using the chromatographic method (where the fat is cut, melted and filtered) - in this case the methylation and subsequent steps were not necessary.

Furthermore, after the application of the VSM technique, a comparison of Fig. 3 and 4 has been made to review the lead time, showing that less time was needed to complete the process and that no efficient operations were identified by applying Lean Management concepts to eliminate waste (Fullerton et al., 2001; Rahani and Muhammad, 2012; Chen et al., 2013; Khanchanapong et al. 2014).

When the FA profile was predicted using NIR technology, the information flow time was reduced from an average of 46 hours (samples processed by GC) to 6 hours (samples processed by NIR technology), as measured by a stopwatch (86% less than currently). Consequently, the total lead time was reduced from 61 h in the current state (Fig. 3) to 40 h (Fig. 4) and using both lean management and NIRS, the at-line application time is reduced by 35%.

Fig. 3

Product process flow. (a) Current state VSM, (b) time variation in slaughter work station, (c) frequency histogram lead time GC.

*Cycle Time (C/T), Value added time (VA/T), Non value added time (NVA/T). *

Fig. 4

Improvement lead time (changing the analysis technique from GC to NIRS analysis of melted fat samples).

(a) future state VSM, (b) frequency histogram lead time NIRs batch.

*C/T= cycle time; NVA/T= No value added time; VA= Value added. *

The second proposal involved the analysis of each individual intact fat sample using NIRS technology.

This was achieved by using a rapid, non-destructive NIR instrument for the intact fat samples, thus providing the ham curing industry with an instant response to make decisions and help organize product batching.

In this case, the process flow was the same as that used in the first proposal (Fig. 4). Lead time was even shorter than in the first proposal because it was not necessary to prepare the sample for analysis. The total time taken to analyse all the samples in the second proposal was lower than in both the current state and the first proposal.

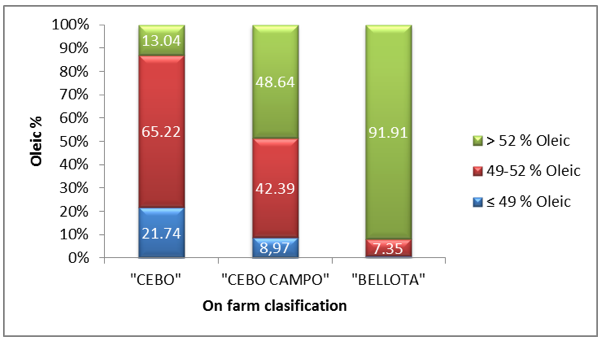

When analysing batches by categories (Fig. 5), it was obvious that in the on-farm classification assigned, each batch of the samples were given a similar oleic acid percentage (≤ 49%, 49-52%, > 52%). It can therefore be seen that in some samples, the category was overestimated or underestimated, and possible wastage could take place, leading to processing that does not accurately take into account the conditions of the product.

Fig. 5

Samples distribution inside the batches

It can be noted, in Fig. 5, that while the percentage distribution in a “Cebo” batch is heterogeneous, 78% of the samples exceed the expected percentage of oleic acid within the category. In “Cebo campo” batches, approximately 9% and 49% of the samples are below or above the expected value of oleic acid, respectively. In the case of “Bellota” batches, the percentage distribution is more homogeneous, with almost 92% of the samples over the expected concentrations of oleic acid.

This heterogeneity of the batches suggests it is relatively easy chance to handle them incorrectly in the industry, due to the variable composition of the fatty acid profile.For all the batches analysed in this study, the probability of error is higher in the “Cebo” category, as regards the official on farm classification (n= 4 batches), with a probability of error of 0.72, followed by “Cebo campo” (n= 31 batches) and “Bellota” categories (n= 3 batches), with a probability of error of 0.62 and 0.12 respectively, which means that the “Bellota” category has have the lowest probability of error.

The information from this study shows, then, that it is highly likely for there to be a degree of error. When the batch classification is used to decide on a particular treatment or technological process without considering each individual characteristic, this can lead to assigning the wrong process to individual Iberian pig hams and shoulders. This situation results in the incorrect classification of salting process for hams, produces variability in the end product and causes possible wastage due to quality defects e.g. decomposition of ham during the curing process, as explained by Serra et al. (2005) and Toldrá (2005). All these errors result in a waste of time and productivity during the process (De Steur et al., 2016).

The results show that in proposals 1 and 2, the slaughterhouse could successfully integrate Lean Management with the NIR technology in order to satisfy customer requirements, as suggested in the case of other technologies (Alas, Zernand-Vilson, & Vadi, 2012; Chen et al., 2013; Khanchanapong et al., 2014).

One logical further step in embracing the new technology would be to incorporate online NIR analysis. In this case, real-time analysis of the samples would be possible, with faster material and information flows (Fig. 6) for quick classification (Zamora-Rojas et al., 2013).

Fig. 6

Improvement lead time (possible changing the analysis to NIR on-line).

*C/T= cycle time; NVA/T= No value added time; VA= Value added. *

Using a real simulation, we would be able to carry out sampling online by which each animal would be analyzed individually with a mean time per analysis of approximately 3 minutes. We would also reduce transport waste, because samples would not need to be sent to an external laboratory, only information to help with calibration. The hams would only have to wait as long as the normal slaughter process takes, before they are delivered to the customer: in this case, the lead time would be about 40.5 h, increasing production flexibility as stablish Buehlmann and Fricke (2016).

To sum up, the integrated use of Lean technology has allowed us to assess the potential and impact of incorporating all the existing advances in NIR technology, such as measuring the characteristics of the original product in the production chain and evaluating the possible alternatives, characteristics, number of devices, and others. All in all, these advances could significantly improve the efficiency and safety of the production process of hams.

This proposal also involves investment in both equipment and computer systems in order to process the information and maintains traceability.

When Iberian pigs are slaughtered, the fatty acid profile is analyzed for internal control. As shown in the previous sections and the process flow requested by the “customer”, the proposed methods for the analysis of the FA profile could offer competitive advantages.

To evaluate the improvement, we have compared the above-mentioned proposals with the current commercial classification.

Comparing GC and NIRS, the classifications show slight differences, as commented previously (introduction), in the error in the fat liquid and intact samples analyzed by NIRS (0.32 and 0.85 respectively). These were higher than those obtained by the current alternative (GC error: 0.25), but when the total error is considered, the difference is not very great (sampling error included), according to Zamora-Rojas et al., (2013). The mean analysis time is reduced from 46 h (batch fat liquid by at-line NIRS) to 0.05 h (intact samples by NIRS online), thus allowing for a faster delivery of the results of the analysis and the classification of the batches before the salting process takes place.

To make the at-line and online tools stronger and more effective, it is necessary to increase the number of samples used in the calibration set, as the more variability considered, the better prediction will be.

The cost of introducing online NIR depends on the characteristics of the equipment and the calibration installed. As a reference, the cost could be estimated at 75,000 euros (including equipment, calibration/validation and maintenance). With an amortization of investment in 10 years, the cost would be 7,500 euros per year, which represents for each campaign 64% of the cost of analyzing batches via NIR, and 40% of the cost of analyzing the batch via GC, both carried out in an external laboratory.

In the industry, incorporating the on line measurement is a viable option but it has repercussions on the process of classification before the expedition, since the computer system now must destine product to the different categories not only according to the weight, but also according to the percentage of fatty acids. The informatics equipment must be programmed.

For customers who usually consume high quality food products, it is essential to offer homogenous products. However, this is impossible if the same processes and treatments are applied to raw material with different fatty acid profiles. Major differences between animals (extensive livestock) can be caused by an irregular acorn intake (Zamora-Rojas et al., 2013), which means that an effort should be made to apply an individual analysis.

In order to review the proposals with Lean criteria, a subjective assessment of the waste produced in the current situation, as well as radical proposals for using this technology, are summarized in Table 1. The impact on wastage has been evaluated on a scale of 1 to 3, with 1 a very low impact and 3 a high impact.

Comparing the 7 typical wastes, it is clear that the NIR option for individual analyses is the option that offers the greatest benefits.

With regard to transport, both the GC and NIR batch have less impact than the online proposal, because the samples must be transported to an external laboratory for analysis. However, with the online option, it would only be necessary to take the measurement from the carcass. However, if eliminating the transport is not a priority, NIR batch technology, carried out with the right product management and technology, would meet customer requirements (Riezebos and Klingenberg, 2011).

As regards the storage of hams in refrigeration chambers, they should be stored for 24 hours after slaughter. If the results of the analysis from GC are expected, the inventories will be doubled in the slaughterhouse. These inventories could therefore be improved by using the proposed NIR analysis, both at-line and online, to reduce waste, as suggested by Chen et al. (2013).

In the current situation, or in the NIR batch samples which are taken in the same way, these proposals would not have any important effects on the operator's movements. In the hypothetical case of an online NIR analysis, no samples are taken but the carcasses are analyzed directly.

With respect to the waiting time, the advantages are progressive between one method and the other, due to a reduced lead-time for each method of analysis. The time an analysis takes using these three methods is 46, 6, and 0.5 hours for the methods GC, at-line NIR and online NIR, respectively. So, as Cuatrecasas et al. (2011) suggest, the improvement in the process can be appreciated in the adjustment in the cycle time of the analysis, which gives added value for the customer.

As regards over-production, none of the proposals shows any difference from the current situation. Contrary to the previous case, the waste involved in over-processing has led to an important change in the proposals. If the real condition of the raw material is unknown and the salt of the hams is incorrectly managed, defects can be produced. If the proportion of weight to fatty acid content in each ham is not considered, the final product will be too salty, which is an important defect in Iberian pig hams at a sensory quality level as well as an unnecessary investment of time and money.

If the salting process is lower than recommended, waste can be found in future stages, because the drying process will be slower and may be unfinished, which increased costs, as the defects can affect the safety and quality (texture, taste, flavour and colour) of the final product (Martuscelli et al., 2017).

The results of this work are also applicable transversally to Iberian pig slaughterhouses, which, according to figures reported by ASICI, account for 14% of all 386 slaughterhouses in Spain (AESAN, 2017), and there are certainly other synergy opportunities to be analyzed and explored between Lean technology and other technology in the food sector.

The combination of different Lean management tools aimed exclusively at improving quality, such as Kaizen meetings and Value Stream Mapping, with NIR spectroscopy as a technological support tool, have enabled us to reduce Lead time, as well as to improve the classification of individual samples. This allows us to manage the raw material better in the different salting processes, thus reducing waste through overproduction and defects in the final product, which will lead to a better use of resources, efficiency and opening the door to necessary innovation. Reducing costs and waste while focusing on quality in food industry, to ensure maintain on board the most important variables in this industry, which add value to the customers. Although further work is needed in order to reduce waste in the Iberian pig industry based on NIRS, this proposal is certainly applicable to other slaughterhouses of Iberian pigs, as well as to the entire meat production sector.

This research was co-founded by the Campus de Excelencia Internacional Agroalimentario (ceiA3), the Ministerio de Educación Cultura y Deporte/Ministerio de Economía y Competitividad and Banco Santander.

Abdulmalek, F., & Rajgopal, J. (2007). Analyzing the benefits of lean manufacturing and value stream mapping via simulation: A process sector case study. International Journal of Production Economics, 107(1), 223–236.

Abdulmalek, F., Rajgopal, J., & Needy, K. (2006). A classification scheme for the process industry to guide the implementation of lean. Engineering Management Journal, 18,15-25.

Abidi, M., Lyonnet, B, Chevaillier P, & Toscano, R. (2016). Contribution of Virtual Reality for Lines Production’s Simulation in a Lean manufacturing Environment. International Journal of Computer Theory and Engineering, 8(3) 182-189.

Alas, R., Zernand-Vilson, M., & Vadi, M. (2012). Management techniques in Estonian organizations: learning organization and business process reengineering. Procedia-Social and Behavioral Sciences, 62, 494- 498.

Behzadi, G., O'Sullivan, M, Olsen, T., Scrimgeour, F., & Zhang, A. (2017). Robust and resilient strategies for managing supply disruptions in an agribusiness supply chain. International Journal of Production Economics, 191: 207–220.

BOE (2004). Orden PRE/3844/2004. Orden, de 18 de noviembre, por la que se establecen los métodos oficiales de toma de muestras en canales de cerdos ibéricos y el método de análisis para la determinación de la composición de ácidos grasos de los lípidos totales del tejido adiposo subcutáneo de cerdos ibéricos. BOE nº 283.

BOE (2014) Real Decreto 4/2014, de 10 de enero, por el que se aprueba la norma de calidad para la carne, el jamón, la paleta y la caña de lomo ibérica. Boletín Oficial del Estado, 10, 1569-1585 (marginal 318).

Buehlmann U. & Fricke C. F. (2016). Benefits of Lean transformation efforts in small- and medium-sized enterprises. Production & Manufacturing Research, 4:1, 114-132.

Chen, J., Chen, C., Huang, P., Wang, K. J., & Huang, C. J., Ting, T. C. (2013). Warehouse management with lean and RFID application: a case study. The International Journal of Advanced Manufacturing Technology, 69,531-542.

Cuatrecasas-Arbos, L., Fortuny-Santos, J., & Vintro-Sanchez, C. (2011). The Operations-Time Chart: A graphical tool to evaluate the performance of production systems – From batch-and-queue to lean manufacturing. Computers & Industrial Engineering, 61, 663–675.

De Pedro, E., Casillas, M., Miranda, C. M. (1996). Microwave oven application in the extraction of fat from the subcutaneous tissue of Iberian pig ham. Meat Science, 45, 45-51.

De Steur, H., Wesana, J., Dora, M., Pearce, D., & Gellynck, X. (2016). Applying Value Stream Mapping to reduce food losses and wastes in supply chains: A systematic review. Waste Management, 58, 359–368.

Dora, M., Kumar, M., Van Goubergen, D., Molnar, A., Gellynck, X. (2014). Application of lean practices in small and medium sized food enterprises. British Food Journal. 116, 125-141.

Dora, M., Kumar, M., Van Goubergena, D., Molnara, A., & Gellyncka, X. (2013). Operational performance and critical success factors of lean manufacturing in European food processing SMEs. Trends in Food Science & Technology, 31, 156-164.

Flores, M., Aristoy, M. C., Antequera, T., Barat, J. M., & Toldrá, F. (2012). Effect of brine thawing/salting on endogenous enzyme activity and sensory quality of Iberian dry-cured ham. Food Microbiology. 29 (2).

Fullerton, R., Cheryl, S., & McWatters. (2001). The production performance benefits from JIT implementation. Journal of Operations Management, 19(3), 81–96.

García, J. (2002). Clasificación y autentificación de canales de cerdo Ibérico mediante espectroscopía en el infrarrojo cercano (NIRS). (Dissertation). University of Córdoba. Córdoba.

García-Olmo, J., Garrido-Varo, A., & De Pedro, E. (2009). Classification or real farm conditions Iberian pigs according to the feeding regime with multivariate models developed by using fatty acids composition or NIR spectral data, Grasas Aceites, 60, 233-237.

Goncharuk, A. G. (2009). How to make meat business more effective: a case of Ukranie. British Food Journal, 111, 583-597.

Jones, D., & Womack, J. (2013). Lean thinking: banish waste and créate wealth in your corporation. 3rd. Ed. Gestión 200, Barcelona.

Kennedy, I., Plunkett, A., & Haider, J. (2013). Implementation of lean principles in a food manufacturing Company. Lecture Notes in Mechanical Engineering, 7, 1579-1590.

Khanchanapong, T., Prajogo, D., Sohal, A., Cooper, B., Yeung, A., & Cheng, T. (2014). The unique and complementary effects of manufacturing technologies and lean practices on manufacturing operational performance. International Journal of Production Economics. 153,191-203.

Kuhlang, P., Edtmayr, T., & Sihn, W. (2011). Methodical approach to increasebproductivity and reduce lead time in assembly and production-logistic processes. CIRP Journal of Manufacturing Science and Technology, 4, 24–32.

Mahalik, N. P. (2010). Editorial Trends in Food Science & Technology, 21, 115-116. Mahalik, N. P, & Nambiar, A. N. (2010). Trends in food packaging and manufacturing systems and technology. Trends in Food Science & Technology, 21,117-128. Martuscelli, M., Lupieri, L., Sacchetti, G., Mastrocola, D., & Pittia, P. (2017). Prediction of the salt content from water activity analysis in dry-cured ham. Journal of Food Engineering, 200, 29-39.

Nychas, G., Panagou, E., & Mohareb, F. (2016). Novel approaches for food safety management and communication. Current Opinion in Food Science, 12, 13–20.

Pérez-Juan, M., Afseth, N., González, J., Díaz, I., Gispert, M., Font i Furnols, M., Oliver, M., & Realini, C. (2010). Prediction of fatty acid composition using a NIRS fibre optics probe at two different locations of ham subcutaneous fat. Food Research International. 43,1416-1422.

Rahani, A. R, & Muhammad, al-A. (2012). Production Flow Analysis through Value Stream Mapping: A Lean Manufacturing Process Case Study. Procedia Engineering, 41, 1727-1734.

Riezebos, J., Klingenberg, W. (2009). Advancing lean manufacturing, the role of IT. Computers in Industry 60:235–236

Seong, P., Kim, J., Cho, S., Kang, D., Kang, G, Park B, … Kim, D. (2010). The effects of salt and NaNO2 on fatty acid composition, free amino acids, microbial counts and sensory characteristics of dry-cured ham processed under Korean environment. Korean Journal for Food Science of Animal Resources, 30, 435–442.

Serra, X., Ruiz-Ramırez, J., Arnau, J., & Gou, P. (2005). Texture parameters of dry-cured ham m. Biceps femoris samples dried at different levels as a function of water activity and water content. Meat Science, 69:249–254.

Serrano, A, De Pedro E, Moreno C, Vazquez P, Moreno A, Garrido-Varo A, … Nuñez-Sanchez, N. (2012). Individual characterization of Iberian pig through NIRS technology: Implementation in Sierra de Sevilla S.A. In: De Pedro EJ, Cabezas AB (eds) Options mediterraneennes, 7th edn. Zaragoza, España pp 615-619.

Sihn, W., & Pfeffer, M. (2013). A method for a comprehensive value stream evaluation. CIRP Annals - Manufacturing Technology, 62,427-430. Simons, D., & Taylor, D. (2007). Lean thinking in the UK red meat industry: A systems and contingency approach. International Journal of Production Economics, 106 70–81.

Tanco, M., Santos, J., Rodríguez, J., & Reich, J. (2013). Applying lean techniques to nougat fabrication: a seasonal case study. The International Journal of Advanced Manufacturing Technology, 116, 125-141.

Toldrá, F. (2005). Safety and quality of traditional foods. Trends in Food Science & Technology.

Ventanas, J. (2001). Tecnología del jamón ibérico. De los sistemas tradicionales a la explotación racional del sabor y el aroma. Ediciones Mundi-Prensa, España.

Wang, Y., Cullinane, K. (2008). Measuring Container Port Accessibility: An Application of the Principal Eigenvector Method (PEM). Maritime Economics & Logistics, 10, 75–89.

Zamora-Rojas, E., Garrido-Varo, A., De Pedro-Sanz, E., Guerrero-Ginel, J. E., & Pérez-Marín, D. (2013). Prediction of fatty acids content in pig adipose tissue by near infrared spectroscopy: At-line versus in-situ analysis. Meat Science, 95, 503-511.

Zamora-Rojas, E., Pérez-Marín, D., De Pedro-Sanz, E., Guerrero-Ginel, J. E., & Garrido-Varo, A. (2012). In-situ Iberian pig carcass classification using a micro-electro-mechanical system (MEMS)-based near infrared (NIR) spectrometer. Meat Science, 90, 636-642.

1. CICAP Food Research Centre, Polígono Dehesa Boyal, Parcela 10-13, 14400, Pozoblanco, Department of Bromatology and Food Technology, Faculty of Agricultural and Forestry Engineering, University of Cordoba,Spain. abolivar@cicap.es, analicha28@hotmail.com

2. Department of Bromatology and Food Technology, Faculty of Agricultural and Forestry Engineering, University of Cordoba, Campus of Rabanales, 14071 Cordoba, Spain.

3. CICAP Food Research Centre, Polígono Dehesa Boyal, Parcela 10-13, 14400, Pozoblanco

4. Department of Bromatology and Food Technology, Faculty of Agricultural and Forestry Engineering, University of Cordoba, Campus of Rabanales, 14071 Cordoba, Spain.