Vol. 39 (# 04) Year 2018. Page 1

Jorge DUMAR 1; Patricia LUNA 2; Fabian LAMUS 3

Received: 11/09/2017 • Approved: 10/10/2017

ABSTRACT: In this research, the relation of the bending strength and the Young’s modulus with moisture content was studied for Bamboo Guadua angustifolia Kunth. The experimental methodology consisted in three-point flexural tests with small specimens obtained from the bottom, middle and top parts of bamboo culms. The moisture content of the sample was modified using a methodology that ensures a controlled range of values from 0% to 25%. The behaviors of the proportional limit, ultimate flexural strength and the Young’s modulus as functions of the moisture content were determined by a statistical analysis using their experimental results. The results showed that the values of the proportional limit and the ultimate strength decrease linearly when the moisture content increases, and there was no significant correlation between the Young´s modulus and the moisture content of the sample. |

RESUMEN: En este trabajo se estudió la relación entre la Resistencia a la flexión y el Módulo de Young con el contenido de humedad del Bambú Guadua angustifolia Kunth. La metodología consistió en ensayos de flexión de tres puntos realizados en probetas obtenidas de las zonas baja, media y alta de los culmos de bambú. El contenido de humedad de las probetas fue modificado usando un procedimiento para asegurar un rango controlado de valores entre 0% to 25%. Se determinaron los comportamientos del Límite de proporcionalidad, la resistencia ultima a la flexión y el Módulo de Young como funciones del contenido de humedad mediante un análisis estadístico a partir de los resultados experimentales obtenidos para cada propiedad. Los resultados mostraron que los valores del Límite de proporcionalidad y la Resistencia ultima a la flexión decrecen linealmente con el incremento del contenido de humedad y que no hay una correlación significativa entre el Módulo de Young y el contenido de humedad de la muestra. |

Bamboo Guadua angustifolia Kunth (guadua) is an endemic species from the Neotropics and represents a valuable natural resource, especially in Colombian rural zones, with suitable mechanical properties to be used in civil construction. Additionally, it plays a key role in the proper functioning of the ecosystems, since it acts as a protector and regulator of water regimes in micro and macro watershed fostering biodiversity due to its features (Cruz, 2009). Moreover, since there are low initial costs of bamboo extraction and treatment, the economic cost is lower compared with the usual building materials such as cement and steel which are obtained from high cost manufacturing processes (Ghavami, 2005).

The mechanical behavior of many species of bamboo has been tested by many researchers (Nogata & Takahashi, 1995), (Luna P. , Lozano, Takeuchi, & Gutierrez, 2012), proving it is a natural resource that could be used in structural applications becoming an alternative building material in the development countries, and a solution for the social problem of homelessness and the high cost of social housing construction projects (Ghavami, 2005).

The ignorance of mechanical behavior of construction materials can end up in technical errors that increase the construction costs or the failure probability for some structural elements. Therefore, for using guadua as a structural material it is necessary to evaluate its mechanical behavior under different loads and service conditions (i.e. relative humidity, temperature, and loads deferred in time, among others).

At the Universidad Nacional de Colombia many researches have been conducted in order to establish the guadua mechanical behavior under different loads (Uribe & Durán, 2002) (Pacheco , 2006), the design of joints for guadua structures (Camacho & Páez, 2002) (Lamus, 2008) and their structural performance (Vidal , 2002) (Rivera, 2008) all of this without studying the influence of various external factors such as the relative humidity and temperature; increasing the uncertainty in the actual response when it is used as a construction material (Gonzalez, Osorio, & Garcia, 2002).

Osorio, Vélez, & Ciro (2005) conducted a research to determine the effect of the outer diameter, the element length, the wall thickness and the moisture content on the flexural strength of guadua culms. They tested guadua elements of 2.5m to 3m of span with moisture contents ranged between 9% and 12%, using a four-point bending test. The results showed that the element length, the moisture content, and the wall thickness do not significantly affect the flexural strength of the material; however, the average outer diameter affects the load value at proportional limit for tested culms.

Guitierrez, Takeuchi, & Perozo (2012) also studied how the moisture content of guadua affects the tensile strength parallel to the grain. They carried out tests on samples obtained from three different locations of Colombia with moisture contents ranged between 5% and 35%.

The moisture content variation was guaranteed for each group of samples, and the desired value was reached by immersing them in water for different periods of time. The results showed that the tensile strength parallel to the grain had a significant variation when the moisture content was less than 12% and more than 21%, but there was no variation within these moisture values.

On the other hand, the objective of the research carried out by Leguizamon & Gonzales (2012) was to determine the variation of compressive strength parallel to the grain for guadua with moisture contents ranged between 10% and 20%. They concluded that the compressive strength parallel to the grain decreases with the increment of the moisture content.

The present study was made to establish the relation of the bending strength and the Young´s modulus with the moisture content of Bamboo Guadua angustifolia Kunth samples.

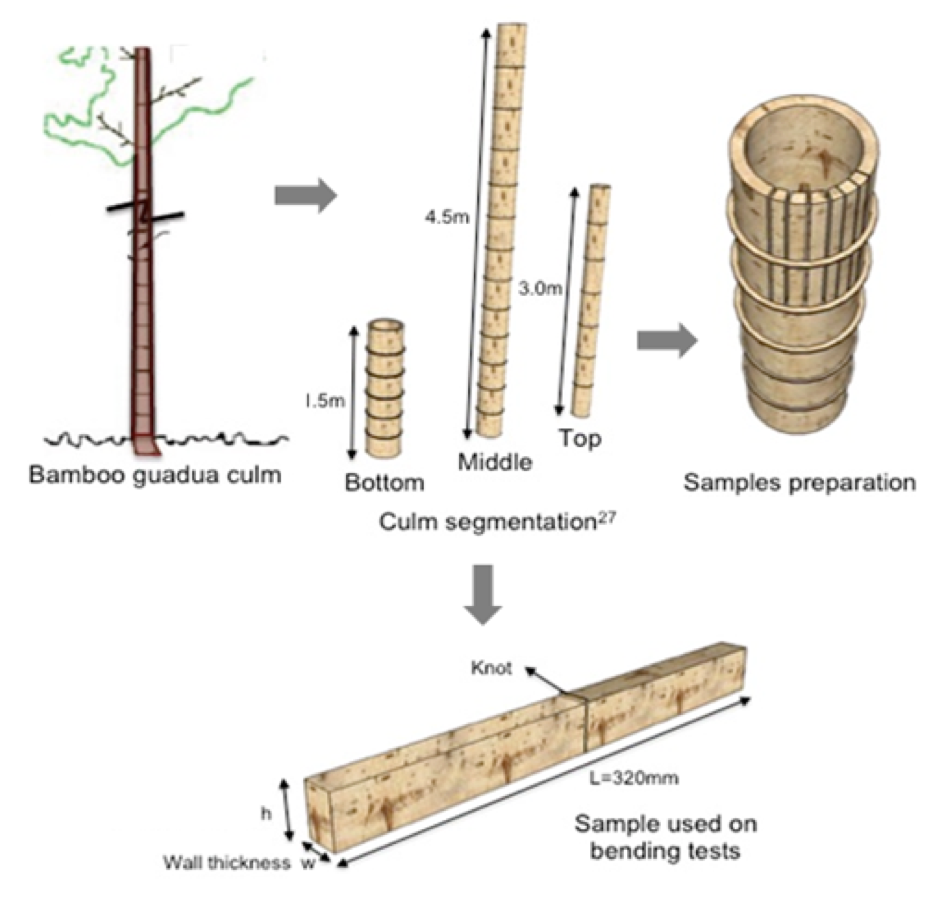

The specimens were obtained from three (3) culms of Bamboo Guadua angustifolia Kunth coming from the region of Quindío and acquired in the local market. The culms were divided in three segments: bottom, middle and top; this procedure was made as established by Luna P. , Lozano, Takeuchi, & Gutierrez (2012). According to the information given by the farmer who provided the guadua, the culms were harvested when they were about 4 or 6 years.

The tested specimens have a rectangular cross-section using a ratio height/width (h/w) of 1.5 and a total length (L) of 320mm. The sample width corresponds to the wall thickness of the culm. Each of the specimens has a knot in the center of the span. A sample of 108 specimens was prepared, 12 from each part (bottom, middle and top) of the three culms. The procedure used for the sample preparation is shown schematically in figure 1

Figure 1

Sample preparation scheme

All the specimens were dried in the oven for 48 hours in order to achieve a moisture content near to 0%; 12 of them were tested with this moisture condition and the rest 96 specimens were immersed in water to obtain a variation of moisture content and then they were tested. The immersion time ranged from 2 to 40 minutes (2, 5, 10, 15, 20, 25, 30 and 40), taking 12 specimens out from the water at each time. With this procedure, the range of the moisture content was from 0% to 25%.

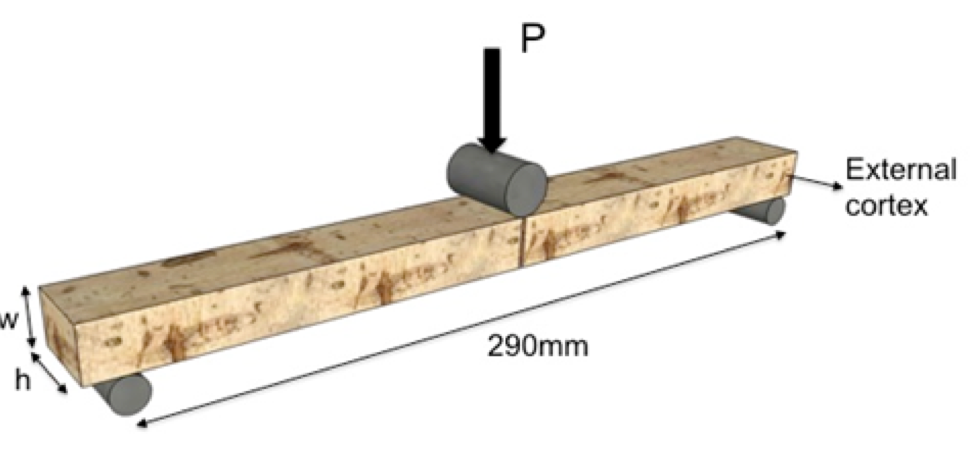

The specimens were mechanically tested using the three- points bending method with the applied load acting at the center of the span. The free span was 290mm. In order to ensure bending failures and the uniform distribution of fibers in the height of the cross section, all specimens were placed with the external cortex parallel to the load direction. The test speed was 2.5mm/min. Figure 2 shows a sketch of the test setting

Figure 2

Three-point bending test.

After the mechanical tests, the moisture contents were computed for all specimens using equation 1, where m is the weight of the specimen before drying and mo is the weight after drying. According to ISO22157 (International Organization for Standardization, 2004), the drying process is complete when the difference in two successive measurements of the weight does not exceed 0.01g.

![]()

Checking the calculated variables (proportional limit, ultimate strength, Young´s modulus and moisture content) scatterplot, it is evident that a simple linear regression model was adopted. Shapiro-Wilk test was used to confirm the normal distribution of each data set.

A coefficient of determination R2 for each model was calculated to assess the model adjustment; this coefficient represents how well the experimental data are represented by the proposed regression function. Since R2 is a quotient of the variances of the fitted values and observed values of the dependent variable and not a measure of a hypothesis test, this value cannot identify whether the result is good or bad by itself. This can be determined if the obtained model represents the observed behavior or not depending on the data model context (Montgomery & Runger, 2002). For this study, R2 was considered appropriate for values greater than 0.10, because the model was performed with a single explanatory variable; additionally, taking into account the anatomical and morphological nature of the bamboo, there were highly variable experimental results in its mechanical properties.

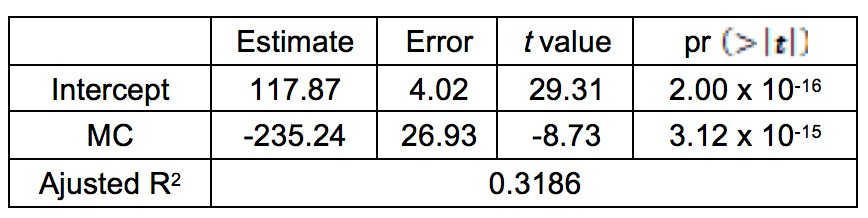

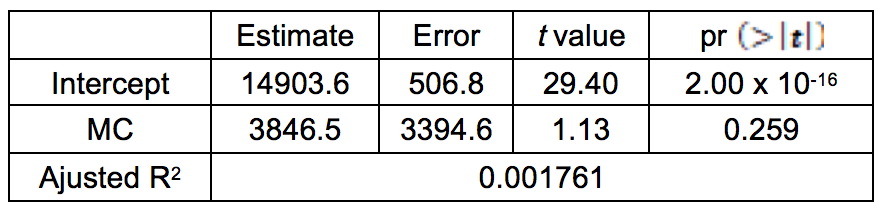

Equation 2 represents the linear regression between the proportional limit and the moisture content, where σLP is the stress at proportional limit in MPa and MC is the moisture content in decimal format ranging from 0 to 0.25. It can be observed that for each 0.01 (1%) increment of the moisture content, the stress at proportional limit decreases 2.35 MPa.

![]()

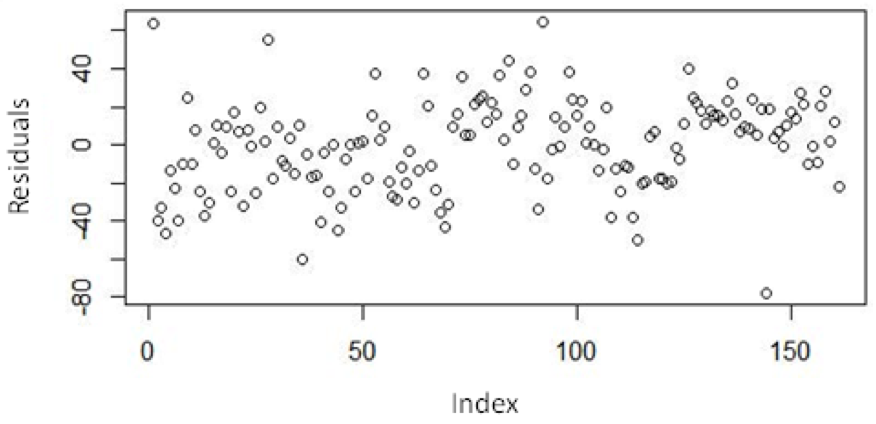

Table 1 presents the coefficient of determination R2 calculated for the proposed model. It can be seen that the model represents the 31.86% of data variability (adjusted R2 value), which is acceptable taking into account the context of the experiment. The p-value result of the application of Shapiro-Wilk test was > 0.05; this indicates that the data set has a normal distribution and the randomness in the distribution of residuals (Fig. 3) ensures the homogeneity of the variance.

Table 1

R2 calculated for the relation between the

proportional limit and the moisture content.

It can be concluded that the proposed model correlating the stress at proportional limit with the moisture content, ensures good predictions and can be used for samples of Bamboo Guadua angustifolia.

Figure 3

Distribution of residuals for the proportional

limit and the moisture content.

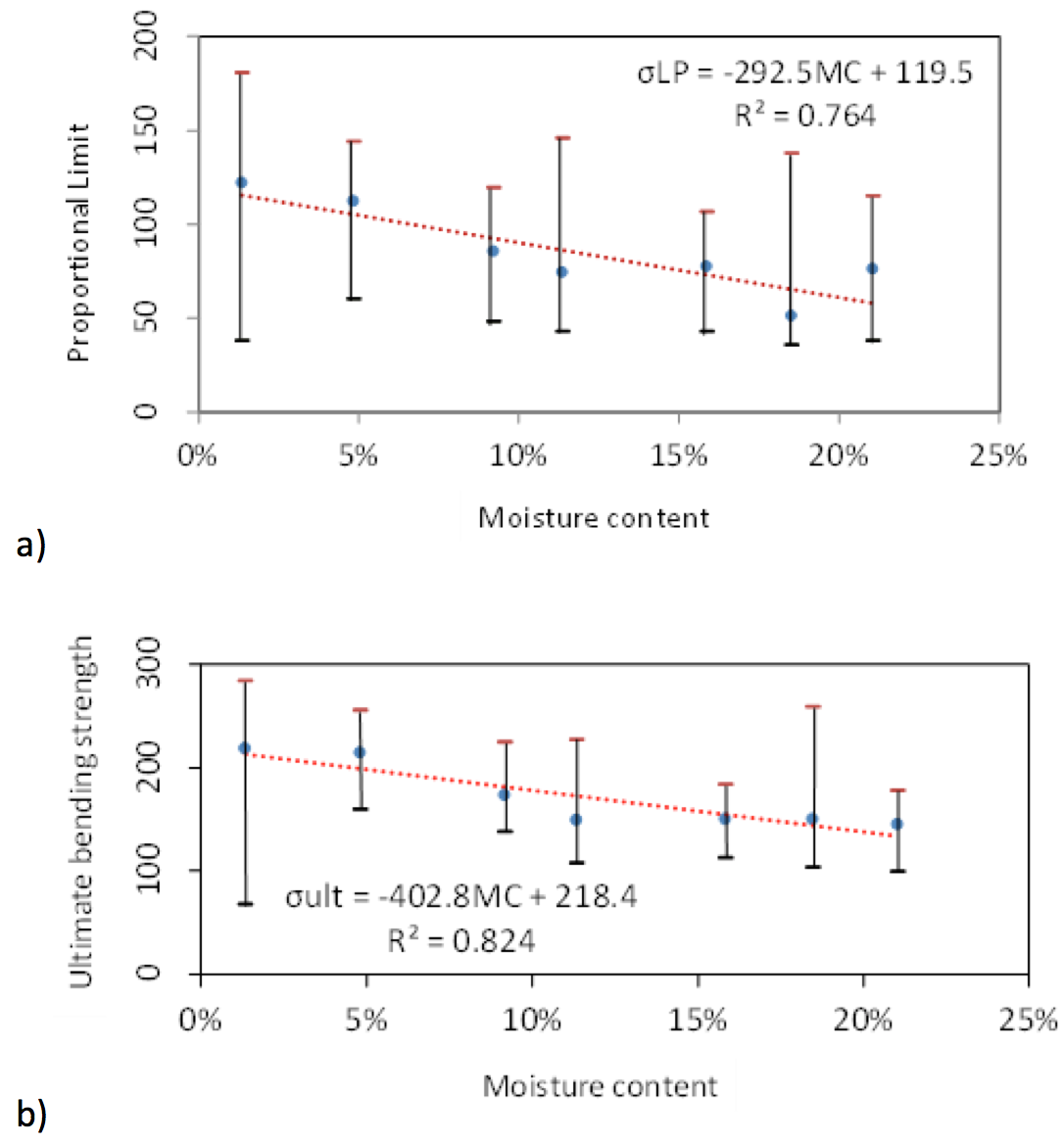

The model proposed for the relation between the ultimate bending strength and the moisture content is presented in equation 3, where σult is the ultimate bending strength in MPa and MC is the moisture content in decimal format ranging from 0 to 0.25. For each 0.01 (1%) increment in the moisture content, the strength at proportional limit decreases 3.78 MPa

![]() (3)

(3)

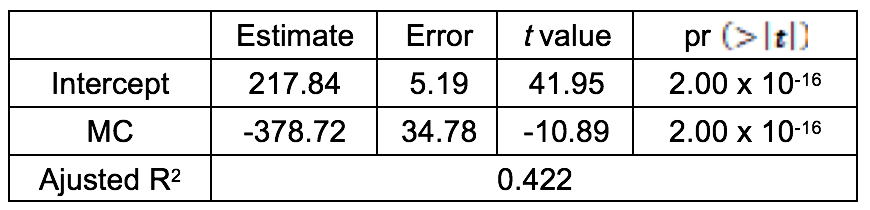

Table 2 presents the statistical values calculated for the proposed model. Equation 3 represents the 42.2% of data variability (adjusted R2 value); which is acceptable for natural materials. The p-value result of the Shapiro-Wilk test is < 0.05, therefore the data set does not have a normal distribution. Hence, equation 3 can only be used as an approximation due to fact that the model validity cannot be completely accepted.

Table 2

R2 calculated for the relation between the ultimate

bending strength and the moisture content.

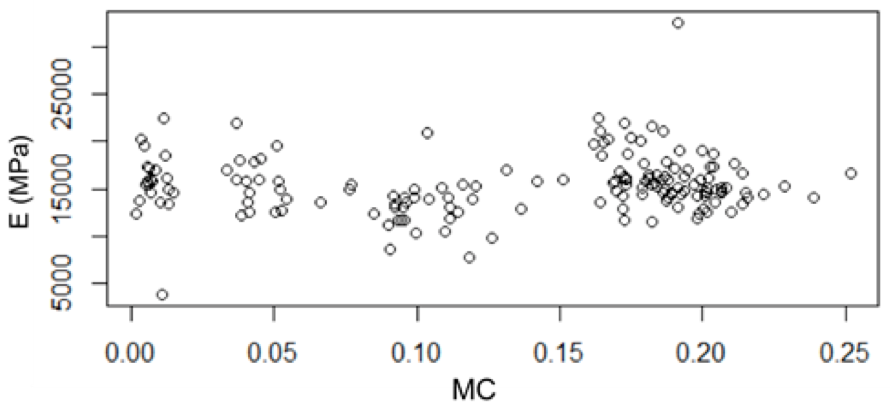

Figure 4 presents the experimental data for the Young´s modulus (E) vs. the moisture content. It is noticeable that there is no relation between these variables; however, a statistical test was conducted to support this assumption.

Figure 4

Young’s modulus vs. moisture content for tested samples.

Equation 4 represents the relation between the Young´s modulus and the moisture content, where E is the Young´s modulus in MPa and MC is the moisture content in decimal format ranging from 0 to 0.25. It can be noticed that the modulus increases 38.46 MPa for each 0.01 (1%) in the moisture content.

![]()

Table 3 presents the results obtained by a statistical analysis; the proposed model (equation 4) presents 0.17% of data variability (adjusted R2 value), which is not significant considering the nature of the material. Due to R2 for this model is lower than the minimum value that is accepted, the normality of data set is not verified. Thus, equation 4 can only be used to calculate an approximated Young´s modulus for Bamboo Guadua angustifolia as a function of the moisture content.

Table 3

R2 calculated for the relation between the

Young’s modulus and the moisture content.

Additionally, using traditional statistics two graphics were made gathering the specimens by classes in order to obtain the average values, leading to a better coefficient of determination R2, as shown in figure 5.

Figure 5

a) Proportional limit vs. moisture content.

b) Ultimate bending strength vs. moisture content.

The experimental methodology and the statistical analysis performed in order to obtain the relation between the bending behavior and the moisture content for Bamboo Guadua angustifolia Kunth were presented in this study. The results showed that the proportional limit decreases with the increment of the moisture content; the same behavior was found for the ultimate bending strength. The proposed model correlating the proportional limit and the moisture content can be used to estimate the value of this mechanical property of Bamboo Guadua angustifolia. The models proposed for the relations between the ultimate bending strength and the Young´s modulus with the moisture content can be used as approximated functions that describe the variation of these properties with the moisture content of the material.

The authors would like to thank the support given by the consulting group of the Statistical Department of Universidad Nacional de Colombia.

Camacho, V., & Páez, I. (2002). Estudio de conexiones en guadua solicitadas a momento flector. Bogotá D.C.: Universidad Nacional de Colombia.

Chung, K. F., & Yu, W. K. (2002). Mechanical properties of structural bamboo for bamboo scaffoldings. Engineering Structures, 24(4), 429-442.

Chung, K., & Yu, W. K. (2002). Mechanical properties of structural bamboo for bamboo scaffoldings. Engineering Structures, 24(4), 429-442.

Cruz, H. (2009). Bambú Guadua.

Echeverri, A. (2007). Comportamiento de uniones en guadua utilizando Fibra de Vidrio. Bogotá D.C.: Universidad Nacional de Colombia.

Flórez, E. (2003). Uniones a tensión en guadua con mortero y varilla. Comportamiento de uniones con uso de expansivo en el mortero. Bogotá D.C.: Universidad Nacional de Colombia.

Ghavami , K., & Marinho, A. B. (2005). Propriedades físicas e mecânicas do colmo inteiro do bambu da espécie Guadua angustifolia. Revista Brasileira de Engenharia Agrícola e Ambiental,, 9(1), 107-114.

Ghavami, K. (2005). Bamboo as reinforcement in structural concrete elements. Cement and Concrete Composites, 27, 637-649.

Ghavami, K., Allameh, S., Sanchez, M., & Soboyejo, W. (2003). Multiscale study of bamboo Phyllostachys Edulis. First Interamerican Conference on Non Conventional Materials and Technologies in the Ecoconstruction and Infrastructure. Paraíba.

Gonzáles, D. (2006). Resistencia a la compresión paralela a la fibra de la guadua angustifolia y determinación del módulo de elasticidad. Bogotá D.C: Universidad Nacional de Colombia.

Gonzalez, E., Osorio, J., & Garcia, E. (2002). Resistencia a la flexión de la Guadua angustifolia kunth a escala natural. Revista Facultad Nacional de Agronomía, 55, 1555-1572.

Guitierrez, M., Takeuchi, C., & Perozo, M. (2012). Variation of Tensile Strength Parallel to the Fiber of Bamboo Guadua Angustifolia Kunth in Function of Moisture Content. Key Engineering Materials, 71-75.

International Organization for Standardization. (2004). ISO 22157-1:2004 specifies test methods for evaluating the following characteristic physical and strength properties for bamboo: moisture content, mass per volume, shrinkage, compression, bending, shear and tension. ISO/TC 165 Timber structures.

Lamus, F. (2008). Calificación de una conexión Viga-columna resistente a momento en guadua angustifolia. Bogotá D.C.: Universidad Nacional de Colombia.

Leguizamon, Y., & Gonzales J. (2012). Determinación de la resistencia a compresión paralela a la fibra de la Guadua angustifolia Kunth en función del contenido de humedad. Bogotá D.C.: Universidad Nacional de Colombia.

León , D., & Sanclemente, A. (2003). Estudio de uniones en guadua con ángulo de inclinación entre elementos. Bogotá D.C: Universidad Nacional de Colombia.

Luna, P., Lozano, J., Takeuchi, C., & Gutierrez, M. (2012). Experimental Determination of Allowable Stresses for Bamboo Guadua Angustifolia Kunth Structures. Key Engineering Materials, 517, 76-80.

Montgomery, D., & Runger, G. (2002). Applied statistics and probability for engineers. Arizona: John Wiley & Sons, Inc,.

Nogata, F., & Takahashi, H. (1995). Intelligent functionally graded material: Bamboo. Composites Engineering, 5(7), 743-751.

Osorio, J., Vélez, J., & Ciro, H. (2005). Efectos de algunos parámetros físicos y geométricos en la resistencia de diseño a flexión de la Guadua angustifolia Kunth. DYNA, 72, 37-44.

Pacheco , C. (2006). Resistencia a la tracción perpendicular a la fibra de la guadua angustifolia. Bogotá D.C.: Universidad Nacional de Colombia.

Pantoja, N., & Acuña, D. (2005). Resistencia al corte paralelo a la fibra de la guadua angustifolia. Bogotá: 2005.

Prada, J., & Zambrano, J. (2003). Estudio de elementos en guadua, solicitados a compresión, con perforación para el relleno de mortero. Tesis. Bogotá: Universidad Nacional de Colombia.

Ray , A. K., Das, S. K., & Ramachandrarao, P. (2005). Microstructural characterization of bamboo. Journal of Materials Science, 5249-5253.

Rivera, J. (2008). Comportamiento Estructural de Pórticos en Guadua Arriostrados Mediante Diagonales en Guadua. Bogotá D.C.: Universidad Nacional de Colombia.

Takeuchi, C., Lamus, F., Malaver, D., Herrera, J. C., & River, J. (2009). Study of the Behaviour of Guadua Angustifolia Kunth Frames. VIII World Bamboo Congress Proceedings (pp. 42-58). Thailand: The World Bamboo Organization .

Uribe , M., & Durán, A. (2002). Estudio de elementos solicitados a compresión armados por tres guaduas - Tesis. Bogotá: Universidad Nacional de Colombia.

Vidal , J. (2002). Diseño y elaboracion a escala natural de armaduras en guadua angustifolia. Bogotá D.C. : Universidad Nacional de Colombia.

1. Ms.C. in Structures, Civil Engineer, Departmet of Civil Engineering, Universidad Nacional de Colombia, Bogotá, Colombia, jrdumarl@unal.edu.co

2. Ph.D. Candidate in Engineerimg, Ms.C. in Structures, Civil Engineer, Lecturer, Departmet of Civil Engineering, Universidad Nacional de Colombia, Bogotá, Colombia, plunat@unal.edu.co

3. Ph.D. in Engineering, Ms.C. in Structures, Civil Engineer, Assistant Profesor, Department of Civil Engineering, Pontificia Universidad Javeriana, Bogotá, Colombia, Fabian-lamus@javeriana.edu.co