Vol. 38 (Nº 46) Year 2017. Page 36

U.Zh. SHALBOLOVA 1; R.A. NARMANOVA 2; E.B. TLESSOVA 3; Zh.O. RYSKULOVA 4

Received: 30/08/2017 • Approved: 07/09/2017

2. Methods and research design: preliminary research studies and experiments

3. Results and discussion: economic part

ABSTRACT: This paper considers the questions of defining the efficiency of the design decision to organize the creation of a mini-plant for mastic production from the waste of crude oil. The results of calculations justified that, by using inexpensive raw materials in the form of oil bituminous rocks and atactic polypropylene, one can reduce the market value of the proposed products. The efficiency of new production development was justified with regard to the net present value, the distribution of costs for future operation periods of a mini-plant, the determination of the payback period and the elaboration of a break-even format for the project solution in accordance with certain formulas and adopted models for determining the economic effect of investment in innovative projects. Economic calculations are based on the results of studying the composition and technology of cold mastic production on the basis of oil bituminous rocks in combination with oil bitumen and polymer additive, which in their properties meet the requirements of GOST (All-Union State Standard), and have better indicators in terms of heat resistance and crack resistance (flexibility on the rod). |

RESUMEN: En este trabajo se plantean las cuestiones de definición de la eficiencia de la decisión de diseño de organizar la creación de una mini planta para la producción de mastique a partir de la pérdida de petróleo crudo. Los resultados de los cálculos justificaron que, mediante el uso de materias primas baratas en forma de aceite de rocas bituminosas y polipropileno atáctiso, se puede reducir el valor de mercado de los productos propuestos. La eficacia del nuevo desarrollo de la producción se justificó con respecto al valor actual neto, la distribución de los costos para los períodos de operación futuros de una mini planta, la determinación del período de amortización y la elaboración de un formato de ruptura uniforme para el solución de proyectos de acuerdo con determinadas fórmulas y modelos adoptados para determinar el efecto económico de la inversión en proyectos innovadores. Los cálculos económicos se basan en los resultados del estudio de la composición y tecnología de la producción de masilla fría sobre la base de rocas bituminosas petrolíferas en combinación con betún de aceite y aditivos poliméricos, que en sus propiedades cumplen los requisitos de GOST ( Estándar del estado de la todo-Unión), y tienen mejores indicadores en términos de resistencia térmica y de resistencia de la grieta (flexibilidad en la barra). |

One of the main directions of the Strategic Plan for Development of the Republic of Kazakhstan until the year 2020 is to ensure “the economy’s sustained growth by way of accelerated diversification through industrialization and infrastructure development” (The Strategic Plan for Development of the Republic of Kazakhstan until the Year 2020). Within the framework of implementation of this task, the adopted State Program of the Industrial and Innovative Development of the Republic of Kazakhstan for 2015-2019 is focused on “the development of the manufacturing industry with a concentration of efforts and resources on a limited number of sectors, regional specialization using the cluster approach and effective industry regulation” (The Decree of the President of the Republic of Kazakhstan No. 874 dated August 1, 2014).

At the present stage of Kazakhstan’s economic development, the most important issues that determine the acceleration of industrial and innovative development include (1) the reduction of material and energy intensity, (2) the improvement of existing building materials and the development of new more efficient ones, (3) the intensification of technological processes, (4) the widespread use of industrial waste and by-products. The relevance of these issues sets a task to find ways to solve these problems in different ways.

Therefore, this paper, devoted to the justification of the economic efficiency of the cold mastic production technology, corresponds to the directions of the state program.

Firstly, for mastic production, this study offers inexpensive raw materials, in the form of oil bituminous rocks, and by-products, in the form of atactic polypropylene, which allows the market value of the proposed products to be reduced.

Secondly, products, in the finished form, will comply with the state standard in terms of such properties as gluing ability, heat resistance, strength and required viscosity.

Thirdly, the proposed simple technology makes it possible to organize the operation of a mini-plant, which should contribute to the provision of Kazakhstan’s market of building materials with cheaper products.

Given that in the foreseeable future, the importance of readily available natural raw materials – oil bituminous rocks – will increase steadily, as limited and expensive oil bitumen dictates the inevitable partial or complete replacement of this raw material type in the composition of waterproofing materials, the relevance of the study will undoubtedly grow.

The justification of the efficiency of new production development was carried out with regard to the net present value, the distribution of costs for future operation periods of a mini-plant, the determination of the payback period and the construction of a break-even format for the project solution in accordance with certain formulas and adopted models for determining the economic effect of investment in innovative projects (Chernyak, 2004; Margolin, 2007; Vilenskiy et al., 2002; Makhnitskaya and Shalbolova, 2012).

The economic benefits of the proposed cold mastic production technology are mainly formed from the partial replacement of expensive oil bitumen with oil bituminous rock and from the use of atactic polypropylene, a by-product of chemical plants.

The economic analysis was carried out on the basis of real studies on the oil bituminous mastic production technology. The characteristics of bitumen structural and mechanical properties were obtained by a preliminary experimental approach; the role and optimal content of each type of product were determined as a component of projected cold mastic compositions [7-9]. Oil bituminous rocks of the Iman-Kara field (the Western part of the Republic of Kazakhstan), 90/10 grade oil bitumen, atactic polypropylene as well as light pyrolysis resin were used as the main raw material for the manufacture of new products. The optimal cold mastic compositions against regulatory requirements were determined by a special instrument according to the method of studying the physico-mechanical properties of the proposed products, which made it possible to determine the rheological characteristics for describing its structural and mechanical properties (Bishimbayev, V.K., Narmanova, 2006; Bishimbayev et al., 1996; Bishimbayev and Narmanova, 2003).

At the initial stage, a number of studies were carried out to determine cold oil bituminous mastic compositions. The preparation of mastic was carried out in laboratory conditions on special equipment. It was revealed that the physico-mechanical properties of the tested mastic compositions meet the requirements of GOST (All-Union State Standard), and have better indicators in terms of heat resistance and crack resistance (flexibility on the rod).

Since the development task included the maximum replacement of oil bitumen with oil bituminous rock, the new products found by rheological research had the optimal ratios of "oil bituminous rock - atactic polypropylene" equaling 1:0.8 and 1:1, and represented the basis, on which mastic compositions were developed. It was found that these relationships provide the sufficient gluing ability, strength and heat resistance of the resulting mastic. This is because the addition of atactic polypropylene to the composition creates a dispersed system where the polymer additive particles swollen due to oil components are dispersed in the bituminous medium. This improves such mechanical properties as elasticity, heat resistance of bituminous materials, and, respectively, mastic. These properties can be manifested only when there is an optimal amount of atactic polypropylene.

This concentration of additives forms a continuous network structure. In this case, it is necessary to strictly control the optimality of the amount of additives, since an increase in the content of atactic polypropylene reduces the gluing ability. This is due to the fact that with an increase in the amount of atactic polypropylene, the volumes of the two phases can initially be approximately equal, and then the phase boundary will disappear, which will become insufficient for the corresponding volume of the hydrocarbon part of bitumen in order to form a strong spatial grid that strengthens the structure of the composition. The optimal mass content of light pyrolysis resin in the composition was 50% of the organic part, which ensured the ease of mixing the components and achieving their homogenization, as well as the ease of applying the resulting mastic to the surface in the cold state without reducing its gluing and strength.

The study of the structural and mechanical properties of the developed mastic compositions at temperatures of 20ºC and 90ºC makes it possible to obtain the complete rheological curves. It is established that as the content of atactic polypropylene increases, the properties of mastic are improved: viscosity, elasticity, heat resistance.

The relevance of the study consists in the integrated use of natural oil bituminous rock in combination with a polymer additive and the creation of a resource-saving cold mastic production technology.

The main consumers of the developed commercial cold oil bituminous mastic products are small and medium-sized enterprises, oriented to industrial and civil construction, construction and repair of waterproofing coatings, construction of bridges and hydraulic structures. The priority of the marketing strategy for effective product promotion is to distribute information among potential consumers, receive feedback from those who used the proposed mastic in the production of their business as well as conduct surveys among regular customers.

The study suggests that a mastic production facility should be located in Western Kazakhstan (Atyrau region), the territory of mining and development of the main primary resources. According to the program, there is a need to purchase a mini-plant for bitumen-polymer mastic production, with a capacity of 40 tons per day (2,000 square meters) and a construction period of 3 months, at a cost of 76,355 USD (23,670,000 KZT at an exchange rate of 310 KZT to 1 USD).

A number of calculations were carried out to determine economic indicators (the planned volume of products with regard to the need for mastic in the warm season, the cost of products manufactured in the first year, the cost of 1 ton of marketable products), taking into account the incomplete workload of this mini-plant in the first year of operation and the need to wait some time until these products completely enter the market and get a foothold in it.

The calculations of the cost of raw materials and 1 ton of mastic, obtained from the results of experimental studies, are presented in Table 1 and Table 2.

Table 1. Calculation of the cost of raw materials for the preparation of 1 ton of mastic

Mastic composition |

Consumption of raw materials: share of components for production of 1 ton, % |

Price for 1 ton of raw materials, USD |

Amount for 1 ton of production, USD |

Existing: Cold bitumen-resin "protector" mastic

Proposed: Oil bituminous rock Oil bitumen Atactic polypropylene Light pyrolysis resin

Total cost of raw materials: |

54,00 23,00 7,50 15.50 |

33,55 306,45 645,16 254 |

1290

1,83 70,5 483,9 55,58

611,84 |

Hereinafter, the presented price and cost indicators are recalculated at an exchange rate of 310 KZT to 1 USD (at the time of writing the article) |

|||

------

Table 2. Cost items for production of 1 ton of cold oil bituminous mastic

No. |

Cost items (for production of 1 ton of mastic) |

Cost, USD |

1 |

Raw materials |

633 |

2 |

Payroll |

153 |

3 |

Operating and depreciation costs |

72 |

4 |

Transport and logistics costs |

82 |

5 |

Overhead costs |

66 |

|

Total |

1,006 |

Thus, the annual saving from the use of the proposed mastic technology in comparison with bitumen-ash mastic is 3,107.5 thousand USD (96,334.0 thousand KZT at the exchange rate) in the production of 1,000 tons of mastic. In addition, it should be noted that proposed mastic has higher values in terms of physico-mechanical properties. At the same time, the saving of deficit oil bitumen in comparison with the existing cold mastic composition is about 50%.

It is also justified by calculations that the cost of cold oil bituminous mastic is 984 USD/ton, while the market value of the analogue is 1,290 USD/ton (Table 3).

Table 3. Indicators of the cost of 1 ton of mastic

No. |

Mastic types |

Cost of 1 ton of products, USD |

1 |

The existing type of products in the markets: Cold bitumen-resin "protector" mastic |

1,290 |

2 |

The proposed type of products: Cold oil bituminous mastic |

984 |

The calculation of the economic efficiency of this investment project solution should be carried out with regard to the discounted profits and discounted incomes of cold mastic production (Shalbolova and Elpanova, 2014(b)).

To determine the criteria for the efficiency of the project solution, summary indicators of the estimated amount of initial capital are shown in Table 4.

Table 4. Calculated indicators of initial capital for the organization of mastic production

Costs |

Costs for 3 months |

Fixed assets including the purchase and installation of a mini-plant for bitumen-polymer mastic production with a construction period of 3 months |

789,000 USD |

The planned volume of production in the first 3 months of the time required to enter the market to the full extent, tons |

140 tons |

Working assets including the cost of raw materials, the payroll of basic and auxiliary workers, operating costs, equipment depreciation, transport and logistics costs, overhead costs |

13,775 USD |

Total amount of required initial capital (with regard to losses in the first 3 months prior to the promotion of finished products in the market at the required level of sales and the composition of the necessary customer database) |

214,097 USD |

Table 5 shows the performance indicators of mastic production, planned incomes and expenses of future periods for the production and realization of marketable products.

Table 5. Performance indicators of cold mastic production

Indicators |

Units |

Number |

Output volume per year |

tons |

1,500 |

Cost of output volume |

thousand USD per 1 year |

1,629.8 |

Annual income from sold marketable products |

thousand USD per 1 year |

1,951.6 |

Average monthly income from sold marketable products |

thousand USD per 1 month |

162.6 |

Planned production cost per output unit |

thousand USD per 1 ton |

0.98 |

Average annual production cost |

thousand USD per 1 year |

1,475.8 |

Average monthly production cost |

thousand USD per 1 month |

123.0 |

Initial cost of a mini-plant for bitumen-polymer mastic production with an installation period of 3 months |

thousand USD |

76.35 |

When developing a marketing strategy for the introduction of a new product into the market, one should take into account the specifics of practical realities. Even with good marketing, it is not always possible to consolidate the demand for products in the market environment. It is important that buyers accept a new product. In this regard, when distributing production by periods and distributing costs, one should bear in mind that in the first months of production, any enterprise might incur losses.

One of the main conditions for the efficiency of the project to organize the manufacture of a new product is to determine the break-even point of the project. Modern economic literature offers various modifications to the definition of the break-even of the investment project, which were previously used in different situations by the authors of the present study (Shalbolova and Elpanova, 2014(a); Shalbolova and Elpanova, 2016).

The break-even point of the design solution is calculated in order to determine the minimum level of production (the use of the enterprise capacity), at which the business will break even. To determine the efficiency of an investment project, there is a need to accurately identify the volume of products necessary for manufacture in order to determine the costs of creating a new product.

Typically, the break-even point of a new design solution is determined analytically and graphically (Savchuk, 2002).

Table 6 summarizes the results of an analytical calculation of the break-even point for cold oil bituminous mastic production. In this example, the output volume is distributed for 2 years by months with regard to a decrease in mastic production in the cold season and an increase in mastic production in the warm season, when construction works that are the main consumers of products are activated.

Table 6. Distribution of planned incomes and expenses of future

periods on the organization of mastic production

Indicators |

Number by periods |

|||||||||||

1 mo. |

2 mos. |

3 mos. |

4 mos. |

4,5 mos. |

5 mos. |

… |

16 mos. |

16,1 mos. |

17 mos. |

… |

24 mos. |

|

Output volume, ton |

30 |

50 |

60 |

80 |

90 |

100 |

… |

100 |

12,5 |

100 |

… |

30 |

Income from sales, thousand USD |

38,32 |

63,87 |

76,65 |

102,2 |

115,7 |

127,7 |

… |

127,7 |

16,0 |

127,7 |

… |

38,32 |

Planned production cost, thousand USD |

29,52 |

49,2 |

59,0 |

78,7 |

88,55 |

98,39 |

… |

98,39 |

12,3 |

98,39 |

… |

29,52 |

Gross profit, thousand USD |

8,8 |

14,68 |

17,61 |

24,06 |

27,2 |

29,35 |

… |

29,35 |

3,67 |

29,35 |

… |

8,8 |

Period expenses |

0,98 |

0,98 |

0,98 |

0,98 |

0,32 |

0,98 |

… |

0,98 |

0,11 |

0,98 |

… |

0,98 |

Taxable profit, thousand USD |

7,84 |

13,71 |

16,65 |

23,01 |

26,87 |

28,39 |

… |

28,39 |

3,56 |

28,39 |

… |

7,84 |

Tax amount, thousand USD (in a simplified form) |

1,15 |

1,92 |

2,3 |

3,1 |

3,32 |

3,83 |

… |

3,83 |

0,47 |

3,83 |

… |

1,15 |

Company profit, thousand USD |

6,7 |

11,8 |

14,35 |

20,03 |

23,66 |

24,55 |

… |

24,55 |

3,1 |

24,55 |

… |

6,7 |

Net (residual) profit (loss), thousand USD |

-96,96 |

-58,2

|

- 43,8 |

-23,66 |

0 |

24,55 |

… |

211,0 |

214,1 |

235,6 |

… |

369,74 |

According to the conditional calculations, the price for 1 ton of products taken for calculations is assumed unchanged throughout the entire investment cycle. Variable costs vary depending on the change in output and, accordingly, on the amount of revenue from sales. Period expenses are determined as fixed costs in the considered calculations. When calculating the amount of taxes, the authors proceeded from the fact that taxation would be applied in a simplified form. The received enterprise profit is the size of undistributed profit. A new enterprise will have the net profit only after the full payback period of the project.

The analysis of the distribution of costs and future revenues shows that the break-even point of the project should come in 2.2 months after the introduction of a mini-plant for mastic production. At that moment, the net profit is zero, which indicates the payback of the initial cost of purchasing and installing technological equipment (mini-plant) for bitumen-polymer mastic production. However, in order to pay back the spent initial capital, 14.5 months are needed from the date of putting a mini-plant into operation, when the planned net profit is 445.31 thousand USD. With regard to the fact that the installation period of a mini-plant is three months, the full payback of the project to organize mastic production will amount to 17.5 months.

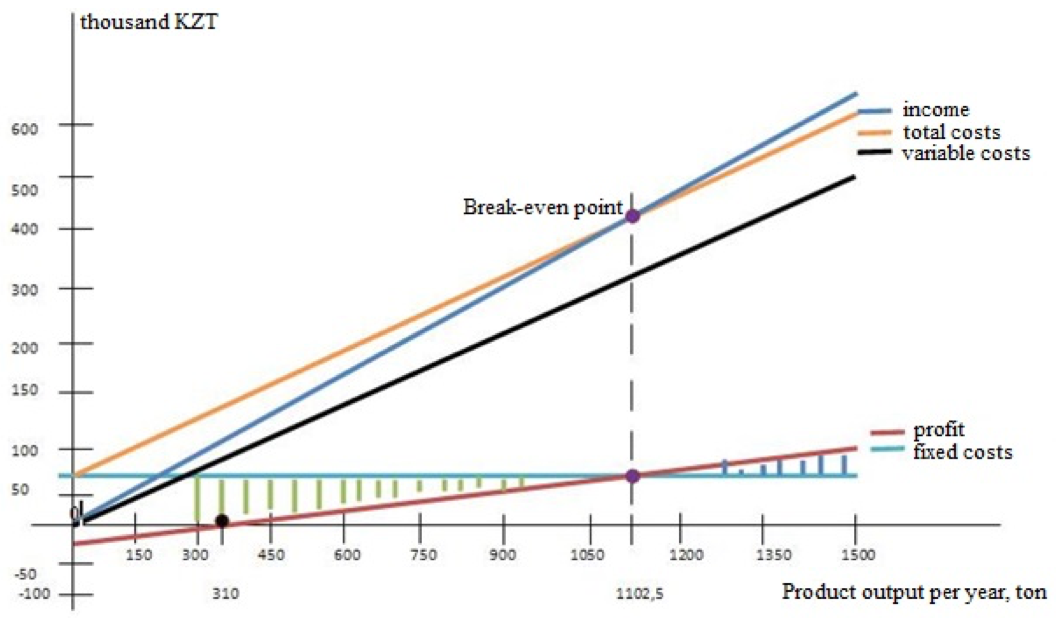

Figure 1 shows the working format of the break-even point of the design solution. By using the data presented in Table 6, one can determine the break-even point of the project. It can be seen from the graph that for profitability the total capacity of using a mini-plant per year should be at least 74%. At the same time, the total annual volume of cold mastic produced should be above 1,102.5 tons. The working format of the break-even point of the project solution also graphically represents the enterprise net profit and losses (the point of intersection of fixed costs and balance profit) (Shalbolova et al., 2004).

Figure 1. The working format of the break-even point of

the design solution for mastic production organization

The value of the break-even point is the basis for determining the risks and strength of the enterprise to the changing situations in the market of the main products.

The implementation of the project to organize mastics production can have various risks, including manufacturing. In our project, one can expect a decrease in the volumes of manufactured, traded and sold products that arose due to the inefficient use of technological equipment, the shortage of raw materials and other circulating resources, as well as a decrease in the competitiveness of products, the break in the chain of product distribution logistics and production, the unjustified use of additional resources for the purchase of materials and raw materials, the over-expenditure of electricity and fuel.

The determination of the payback period, the calculation of the break-even point of the project and the construction of a working format of the break-evenness of the project solution are, as a rule, the priority criteria for the economic efficiency of manufacturing new products and planning for successful business, provided production volumes remain unchanged. However, in practice, the operating conditions of any enterprise can change, which leads to an increase in the break-even point caused by various factors. Thus, the expansion of production volumes will lead to an increase in costs, which will result in a new high break-even point. However, this should be a temporary phenomenon, until the costs aimed at expanding production are paid off. All these possibilities have been taken into account in the calculations in the present study, which envisages the organization of a new enterprise for cold mastic production, the creation of new jobs, which will allow workers to receive a stable income, and the collection of taxes and other deductions to the city budget.

In conclusion, some advantages of a mini-plant should be noted:

- the quality of products due to the technology used: high heat resistance and crack resistance;

- the flexibility of production (the possibility of rapid changes in volumes);

- competitive prices, profitable discount policy.

Bishimbayev, V. K., Narmanova, R. A. (2003). Physico-chemical basis for obtaining cold oil bituminous mastic. Reports of the First International Scientific Nadirov Readings: Scientific and Technological Development of Oil and Gas Industries, Atyrau.

Bishimbayev, V. K., Narmanova, R. A. (2006). Cold waterproofing mastic based on petroleum bituminous rocks of Western Kazakhstan [Monograph]. Almaty: Market, 160 p.

Bishimbayev, V. K., Narmanova, R. A., Shaukhamanov, N. S. (1996). The study of structural and mechanical properties of mastic constituent components based on oil bituminous rocks. Journal of the Ministry of Education and Science of the Republic of Kazakhstan, 6.

Chernyak, V. Z. (2004). Management of investment projects. Moscow: Yuniti-Dana.

Makhnitskaya, E. I., Shalbolova, U. Z. (2012). Regional model of investment innovative processes development. Actual Problems of Economics, 7, 414-426.

Margolin, A. M. (2007). Economic evaluation of investment projects. Moscow: Ekonomika, 367 p.

Savchuk, V. P. (2002). Analysis of break-even and target profit planning in the investment design process. In: Evaluation of the Efficiency of Investment Projects [Textbook]. Moscow: Delo.

Shalbolova, U. Zh., Elpanova, M. A. (2014(a)). Algorithm of reaching break-even for investment projects based on marginal analysis. The New University International Journal. Series: Economics and Law, 10, 7-12.

Shalbolova, U. Zh., Elpanova, M. A. (2014(b)). Evaluation of the efficiency of the investment project. Bulletin of the National Engineering Academy of the Republic of Kazakhstan, 4, 71-81.

Shalbolova, U. Zh., Elpanova, M. A. (2016). The ratio of the break-even point and operational leverage of the enterprise. Bulletin of the National Engineering Academy of the Republic of Kazakhstan, 1, 105-110.

Shalbolova, U. Zh., Satova, R. K., Elpanova, M. A. (2004). Working format of break-even and targeted profit planning in project solutions. Materials of the International Scientific-Practical Conference “Kazakhstan’s Railway Transport: History and Prospects of Economic Growth”, Almaty, 4.

The Decree of the President of the Republic of Kazakhstan No. 874 dated August 1, 2014. The official website of the President of the Republic of Kazakhstan. Retrieved from: http://www.akorda.kz/en/official_documents/strategies_and_programs

The Strategic Plan for Development of the Republic of Kazakhstan until the Year 2020, approved by the Decree of the President of the Republic of Kazakhstan No. 922 dated February 1, 2010. The official website of the President of the Republic of Kazakhstan. Retrieved from: http://www.akorda.kz/en/official_documents/strategies_and_programs

Vilenskiy, P. L., Livshits, V. N., Smolyak, S. A. (2002). Evaluation of the efficiency of investment projects. Theory and practice. Moscow: Delo, 888 p.

1. Department of Economics, L.N. Gumilyov Eurasian National University, Astana, Kazakhstan, Doctor of Economics, Professor, E-mail: urpash_sh@mail.ru

2. Engineering Profile Laboratory, Korkyt Ata Kyzylorda State University, Kyzylorda, Kazakhstan, Head of Laboratory, Assossiate Professor

3. Department of Economics, L.N. Gumilyov Eurasian National University, Astana, Kazakhstan, Candidate of Economic Sciences

4. Department of Economics, L.N. Gumilyov Eurasian National University, Astana, Kazakhstan, Master of Economics, Senior Lecturer