Vol. 38 (Nº 46) Year 2017. Page 30

Raphael Victor FOUREAUX Paulino 1; Alexandre Carvalho MENDONÇA 2; Andressa Amaral de AZEVEDO 3; Tiago Silveira GONTIJO 4

Received: 25/05/2017 • Approved: 13/06/2017

2. Production Planning and Control

ABSTRACT: In the current economic scenario, large companies face difficult competition in the market due to the high level of competitiveness, always trying to produce more with a lower budget. For this, they use specific tools to develop, such as engineering software, market research, among others. The present work aims at discussing the influence that the management of projects linked to the planning of productive capacity impacts on the performance indicators of a work, besides showing the deviations practiced, in order to correct them, aiming the success of the enterprise. |

RESUMEN: En el escenario económico actual, las grandes empresas enfrentan una difícil competencia en el mercado debido al alto nivel de competitividad, siempre tratando de producir más con un presupuesto menor. Para ello, utilizan herramientas específicas para desarrollar, como software de ingeniería, estudios de mercado, entre otros. El presente trabajo tiene como objetivo discutir la influencia que la gestión de proyectos vinculados a la planificación de la capacidad productiva impacta en los indicadores de desempeño de una obra, además de mostrar las desviaciones practicadas, con el fin de corregirlas, apuntando al éxito de la empresa. |

Even facing an economics crisis, the construction sector plays an important role in Brazil's Gross Domestic Product (GDP), which drives the construction materials industry and generates employment and income. Currently, even with the sector down, construction accounts for about 7.078 million employed persons, corresponding to 7.8% of total employment in Brazil (FIEMG, 2017).

The constant changes that have taken place in the economy have led companies to seek improvements in their internal processes, once increasing the efficiency of production processes becomes a key point for the survival of companies. In light of this, it is necessary to plan the actions which will be taken in triggering the processes, in order to conquer and / or maintain the company´s influence in the market.

In regards to these factors, Corrêa and Corrêa (2010) state that the importance of planning is given by the logic that there is a time interval of reaction between the moment of decision making, through the application of the measures defined in the decision, to the effective result.

Considering the construction sector, where the product is a construction work, a quite variable production plan is observed, according to the different phases of the project and also with the different skills qualifications of labor. To achieve the expected results, planning becomes essential to guide decision-making during the process. Once the construction companies are inserted in a highly competitive environment, the proper use of productive resources, in an efficient way, is seen as a necessity for the success of the enterprise.

Through this study, it will be possible to understand the importance of planning and production control for project management, which contains several variables due to the dynamism of the execution of a construction work. In addition, it is known that the measure of work-force is one of the most important aspects in the management of a project. Thus, the project supervisor must be aware of the project's productive capacity, its form of distribution, and whether its funds are spent in the planned way.

Given this scenario, the occurrence of failures in the construction process has become a great challenge for the organizations in this sector. Taking into account the importance of a successful enterprise, the following question arises: What is the degree of operational efficiency achieved in a large construction work?

In general, this manuscript aims to compare the planning of productive capacity with the execution, coherence and adequacy over time, in the construction industry, in view of the high competitiveness observed in the market. Specifically, it is intended:

a) Mapping the construction processes;

b) Establish a Gantt schedule, obeying the global factors of use;

c) Verify the deviations ocurred - predicted x realized, addressing the efficiency of the construction work.

There are, in the literature, some studies that deal with this subject. As examples, can be mentioned the works of Kagioglou (2000), Picchi (2003), Forbes & Ahmed (2011) Krumenauer & Souza (2016). The present study differs from those mentioned above, since it addresses the efficiency of production processes in a construction site, a sector that is lacking in studies in Brazil.

In addition to this introduction, this article contains four more sections. In the next one, there is a brief description of the productive processes. In section three, the methodology used was discussed. In section four, the results were presented and discussed. Finally, in the fifth and last section, the conclusions of the study are described.

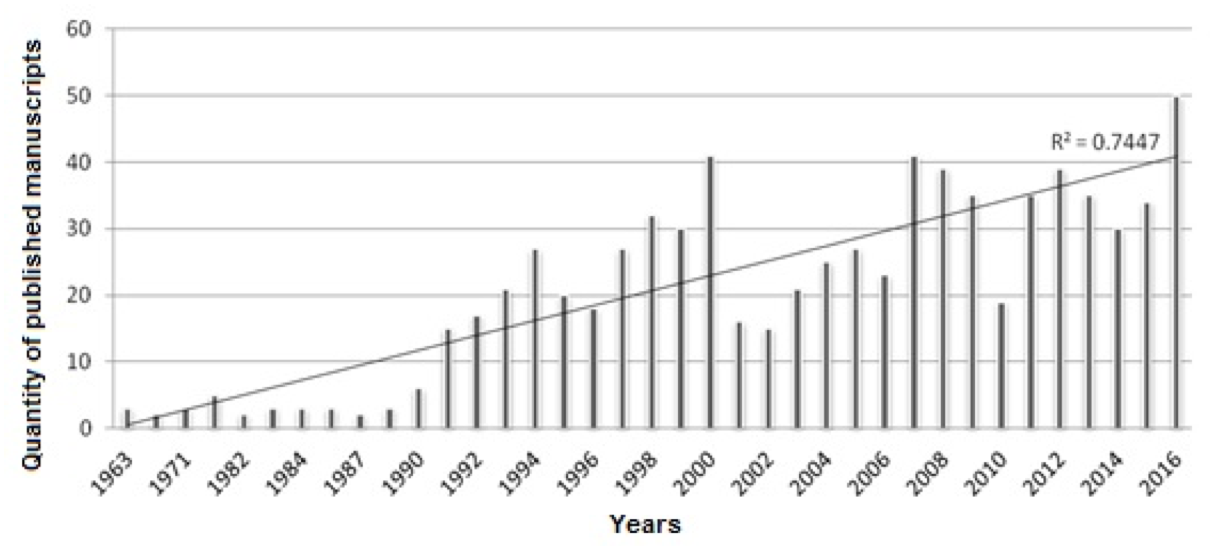

Specifically regarding the state-of-the-art of research on knowledge related to Production Planning and Control, the first procedure performed in the present research consisted of a detailed analysis of the Web of Science (WOS) collection, which consists of a database that provides access to more than 9,200 journal titles. It should be noted that the Coordination of Improvement of Higher Education Personnel (CAPES) signs the full contents of the aforementioned database and provides them to the entire scientific community of the Federal Universities and Institutes of Brazil. In view of the above, the Theoretical Framework of the present article begins with the identification of scientific publications related to the theme: Production Planning and Control (PCP), starting in 1945. For this purpose, it was collected from the base of the WOS, all the history of the world's leading publications.

Figure 1 shows the history of publications, as mentioned in the previous paragraph. It can be seen that the theme related to the expression "Production Planning and Control" is extremely relevant and current, since the growth of the subject has shown to be significant over the years, as evidenced by the trend line. In particular, there are 785 papers related to the aforementioned area, registered in the Web of Science database, of which 468 are scientific articles.

Figure 1 – Publications related to Production Planning and Control since 1945

Source: Search Results (2017).

It should be noted that 30% of the publications on this topic were carried out in Germany, the world leader in studies on Production Planning and Control, followed by the United States (13%), England (10%) and China (7%). Brazil, host country of the present research, ranks 9th in the ranking and has more publications in the Web of Science database than countries like Norway, Canada, Greece and Japan.

It is worth noting that 67% of the researches developed in the area were applications, theoretical and practical in the field of Operational Research (42%) and Computer Science, with 30%. Note that the sum exceeds 100%, since the same Journal can be evaluated in more than one area of knowledge. Among the main works published in the area, the following works stand out:

According to Davenport (1994), the concept of process would be a specific ordering of work activities in time and space, with a beginning, middle and end, inputs and outputs clearly identified, in short, a structure for the desired action. Harrington (1993) defines it as a group of logically linked tasks that use the organization's resources to generate the defined results in order to support its objective.

Specifically in relation to the types of existing processes, it can be said that distinct production units present great variety in their production processes, according to the branch of activity and company profile. In some companies, it is notable the predominance of large equipment while in others, large numbers of people work on an assembly line working side by side, for example.

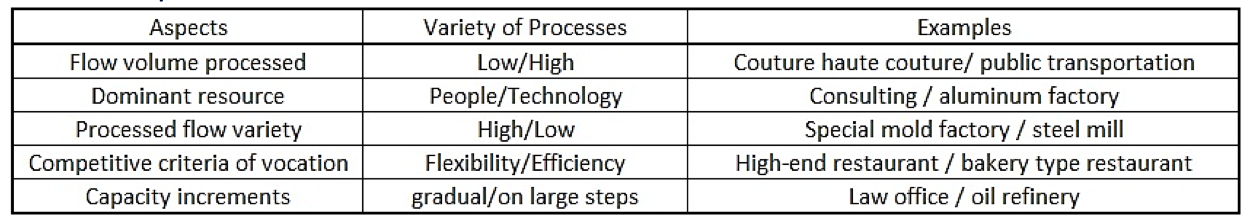

In an attempt to identify patterns in the great diversity of productive processes, Corrêa, Gianesi and Caon (2011) enumerated some aspects in which the productive units differ from each other, according to Table 1.

Table 1: Aspects of Productive Processes

Source: Adapted from Corrêa, Gianesi e Caon (2011)

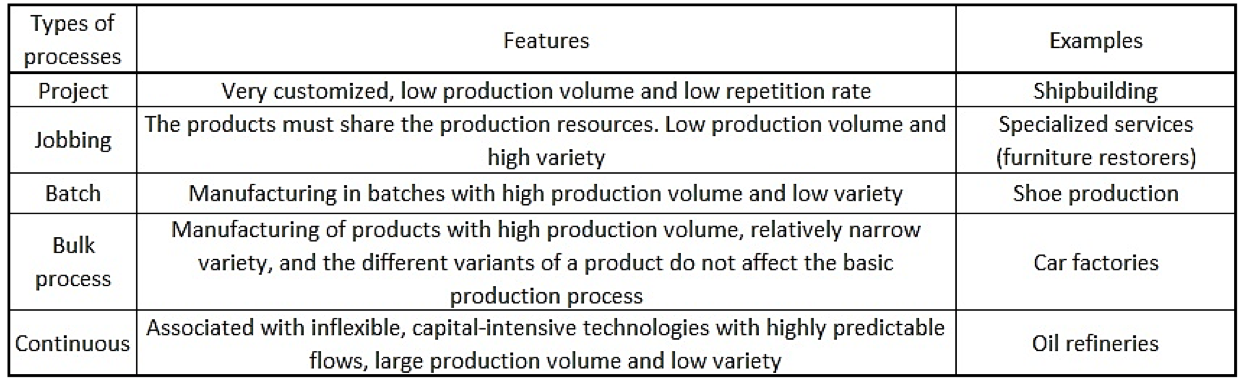

Fernandes and Godinho Filho (2010) point out how frequently there is high processed volume and low flow variety in the same process. Slack, Chambers and Johnston (2009) also characterize the processes in different types, according to Table 2.

In spite of the different nomenclature for the classification of the types of processes, the authors adopt the same idea to list the different types of processes, being the concept basically in the same line of thought.

Table 2: Types of Productive Processes

Source: Adapted from Slack, Chambers e Johnston (2009)

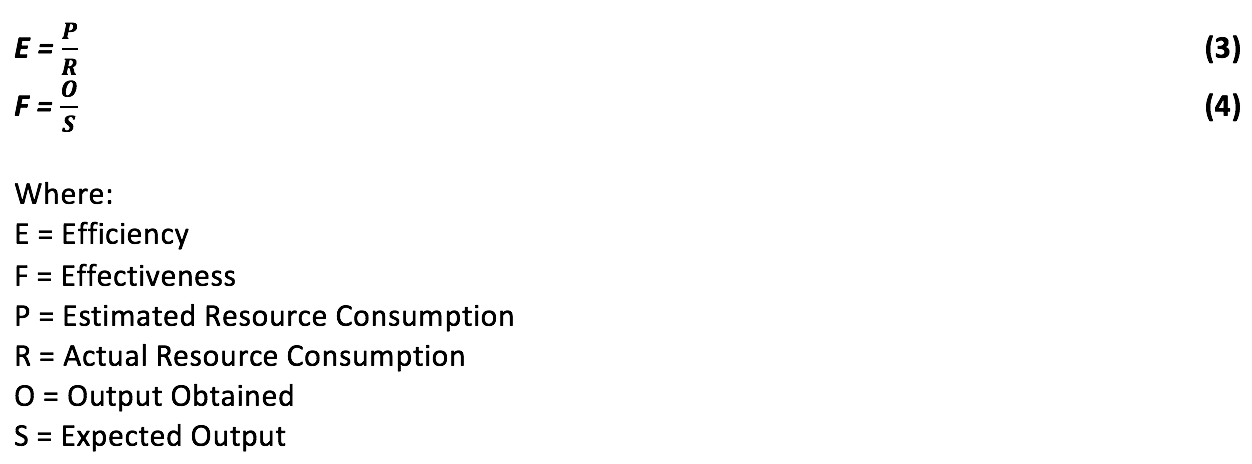

Corrêa, Gianesi and Caon (2011) affirm that performance evaluation is the process that quantifies the action. Furthermore, following a marketing vision, in a competitive environment, to reach their goals, companies must meet the needs of their customers more efficiently and effectively than their competitors. Gaither and Frazier (2001, p.458) define productivity: "it means the quantity of products or services produced with the resources used. Productivity over a time interval is generally measured according to Equations (1) and (2):

Corrêa, Gianesi and Caon (2011) explain that effectiveness refers to the extent to which objectives are achieved, in other words, the needs of clients and other interest groups of the organization (employees, government, society) are met. On the other hand, efficiency is the measure of how economically the resources of the organization are used when they promote certain level of customer satisfaction and other interest groups.

These two concepts, exemplified by formulas (3) and (4), allow the identification of two dimensions of performance, and attentive to the fact that there are internal reasons, referring to the use of resources, and external, referring to the level of service to customers and stakeholders. These reasons serve as a basis for pursuing certain courses of action, according to Corrêa, Gianesi and Caon (2011). Gaither and Frazier (2001) complement determining indexes for measuring productivity over a given time interval. The first called capital, which is the number of products produced divided by the value of the asset. The second material index, is the number of products produced divided by money spent on materials. The third, direct labor: is the number of products produced divided by the hours of direct labor. Finally, the last indicator, general expenses, which is the number of products produced divided by the money spent on overheads.

The study in question was carried out at a large construction company in the metropolitan area of Belo Horizonte, and the company's name was kept confidential throughout the research due to confidentiality issues.

The research is exploratory and contains an applied nature. For its development, a documentary collection was made to obtain data, through sources. Data such as "target dates" and "actual dates" of execution of the processes and real quantity of professionals who were working at the construction work, were provided over the period from January 2016 to March 2017 by the company. These data were collected through the productivity control reports of the construction company, during part of the execution of the construction work studied. In addition to these, there are also historical data of other achievement of the company (construction works of the same standard already carried out), containing the average indexes of productivity of the workers.

The indexes were stipulated by measuring the daily production of each specialized worker, which are the guides of the budget and construction planning. With the data provided, it was possible to perform mapping of the production processes, making a visual identification of all the interactions present in the process as a whole, through a Pert network. After the mapping, the levels of capacity and labor qualification of the construction work were determined, comparing with the historical productivity indexes provided.

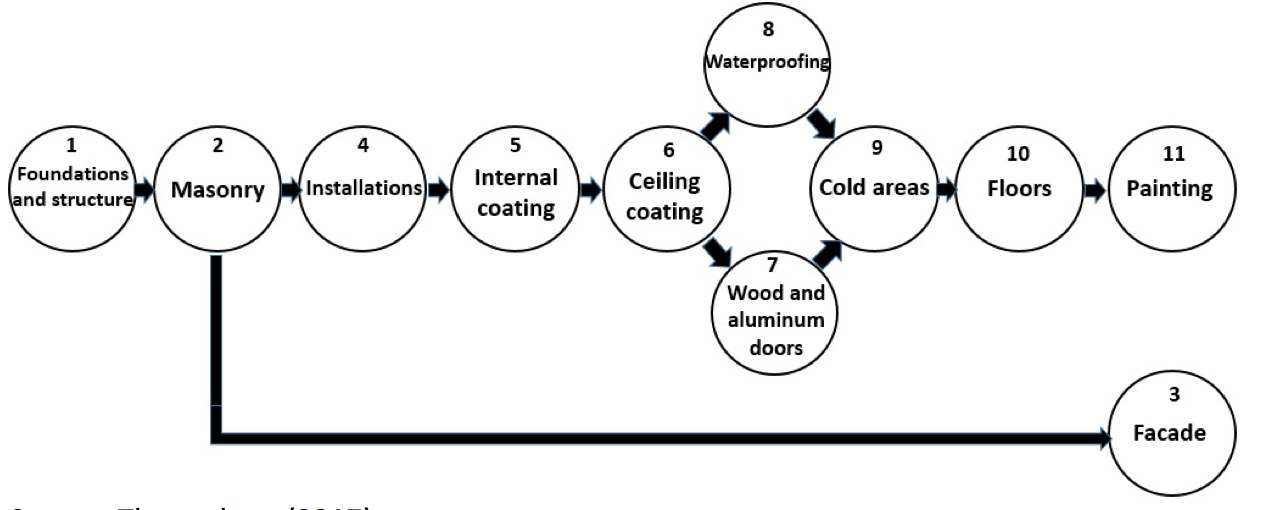

In this section, the process mapping, using the flowchart tool is shown, as well as the results obtained in the analysis about project management and its impact on the performance indicators of the organization. Figure 2 shows the Pert network of the processes involved.

Figure 2: Pert Network - Mapping of processes

Source: The authors (2017)

The activities are sequenced in the diagram of figure 2, obeying the production logic - predecessor and successor activity, based on the construction method predetermined by the company. It is observed that different processes can be executed at the same time (7 and 8) and a relatively independent process (3), which after completion of activity 2, is performed at the same time as the other processes, as it is an activity totally external to the construction work. The following is a description of the competence of each activity:

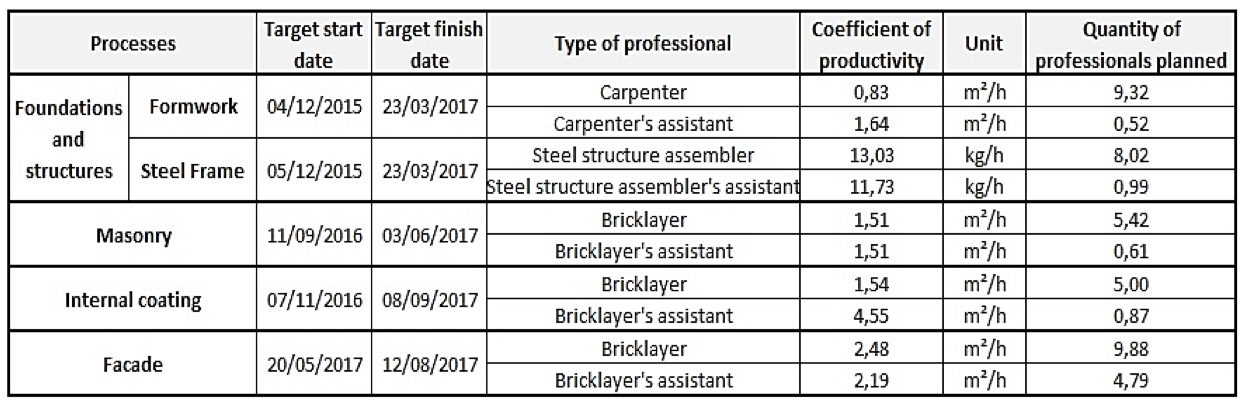

The lead time of each activity was established relating the historical coefficient of productivity of each specialized professional, contained in the company's database, with the expected capital flow and sales planning over time, observing the total quantity of each activity to be produced according to the project of the construction work. Table 3 reveals the global factors of use, analyzed in this article the processes 1, 2, 3 and 5.

Table 3: Global factors of use

Source: The authors (2017)

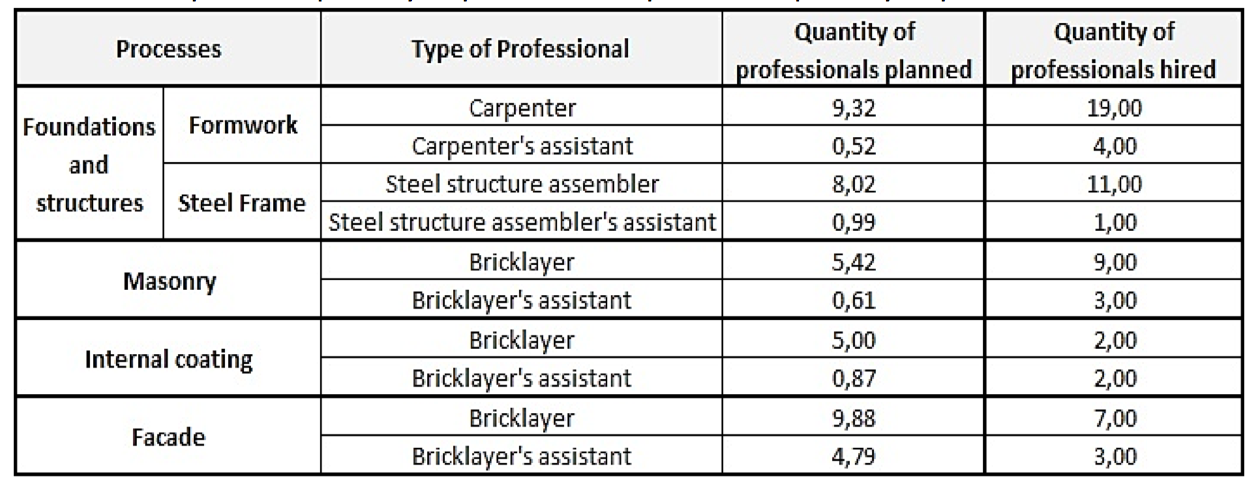

When calculating global factors of use, was considered forty-four hours worked weekly, which is permitted by Brazilian labor legislation, and is practiced by the civil construction industry. Thus, it was defined the optimal amount of workers required to perform each activity, as can be seen in the last column of Table 3. It is noted, however, that there are some variants that distance planning from executable reality in the construction work, such as: absenteeism, poorly qualified labor, climatic conditions. Moreover, factors such as: daily decision making by the leading team of the construction work, which may be contrary of the project flow, urban norms, such as entry and exit of trucks during business hours in the main center of the city of Belo Horizonte. Considering the dynamism of all the stages of a construction work, which might result in distortions of the previously planned, Table 4 illustrates the real quantity of professionals done in this construction work.

Table 4: Comparison: quantity of professionals planned x quantity of professionals hired

Source: The authors (2017)

It is interesting to observe that in all the analyzed processes, the quantity of professionals hired is different from the previously planned one, following the limiters mentioned above. This factor interferes in all the activities of the construction work, which are interconnected, pulling or pushing the schedule, in addition to changing the proposed capital flow, which might even alter the construction process, advancing the delivery or paralyzing the construction work. However, when comparing executed to planned, there are quantitative distortions that are an invitation to reflection. There are ten carpenters more than the predicted quantity, four times the number of carpenter assistants and three extra steel structure assemblers. As the activity was finalized, closely, in the predicted time, the results allow to think that the hired labor was not qualified enough to produce according to the coefficient of productivity used in the planning, and there was a need to hire more professionals in order to meet the schedule. On the other hand, the labor force was idle, due to the existence of too many professionals due to a mismanagement.

The next three processes, masonry, internal coating and facade, use the same types of professionals: bricklayer and bricklayer´s assistant. Therefore, the workers are hired and can be allocated to both sectors, depending on the strategy, guidance and need established by the engineer, who must follow the planning parameters. Since as the product in question is a construction work, there may be services ready for execution of several different processes, predecessors or successors, since the lower floors may be able to receive internal coating while the masonry is being executed on upper floors, as well as the execution of the facade. Thus, the allocation of resources must be made obeying the criteria previously established, so that one process does not benefit to the detriment of another.

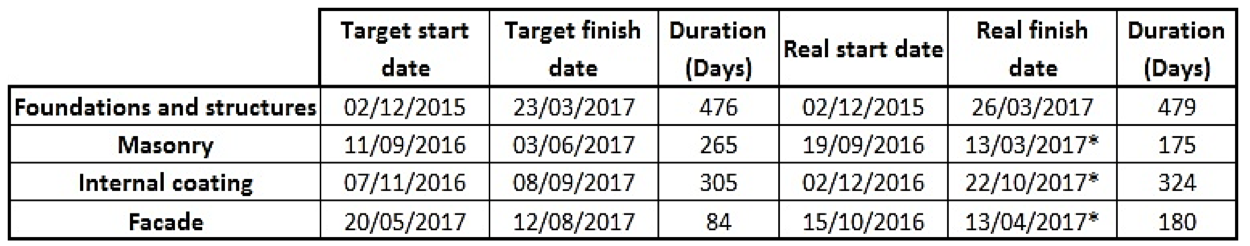

According to Table 4, notoriously, a greater quantity of professionals was allocated than expected for the masonry activity, resulting in anticipated prediction of real finish date of this activity. At the same time, the quantity of professionals hired for internal coating process is smaller than the predetermined one, which led its end to be postponed. Furthermore, it is interesting to note the facade matter. Its amount of professional was undersized, but there is a prediction of early termination, which indicates that even the masonry process has allocated professionals that should be allocated to the facade sector, this activity is responding well to the demand imposed on it. That is, the allocated labor is producing above the coefficient of productivity used in the planning to drive the construction work. Although, it got started earlier than planned, which reveals the strategy taken: lower allocation of professionals – more qualified workers chosen – bigger duration on schedule, but early termination in regards to target finish date. Table 5 illustrates the performance indicators resulting from the construction work described above, in line with the planning performed.

Table 5: Deviations

Source: The authors (2017)

The adoption of project management techniques brings a variety of gains to the organization, such as a better visualization of resource allocation, significant increase in predictability of potential unfavorable situations that can be identified and sequentially undergo corrective actions, development of competitive differentials. Furthermore, project management allows the improvement of relations with all the engaged sectors, adapting the work routines. Thus, helping in decision making, since the information will be made available in a structured and organized way in real time. However, it is worth mentioning that the company will have the benefits of project management according to its maturity in relation to the methodology conveyed by the concepts of this strand.

In addition, it is understood as planning, the stage of support for a good and expected performance of execution and control of all future activities of a project. In this way, the tool allows easy visualization and identification of the most significant and notorious causes or problems for project management. An analysis based on planning allows concentrating efforts on the deviations found, such as poor allocation of resources or delayed delivery of an activity, for example.

This manuscript sought to identify the influence that the management of projects related to the planning of the productive capacity impacted on the performance indicators of a work, immersed in the context of the Brazilian civil construction industry. In this way, it was possible to verify the importance of the information that this methodology is capable of generating, in order to direct the daily decisions of the leading team, to the goal planned by the management, in relation to the predetermined schedule, quantity of professionals hired and budget. Nevertheless, it has been shown that through this tool, it is possible to verify the deviations ocurred, in order to correct them, aiming the success of the enterprise.

Nowadays, due to the high degree of complexity of the projects and the high competitiveness among companies in the market, the use of project management has been widespread among investors and companies. Once the dynamism of the possible variants that might change the planned course of a construction work is known, it is necessary to identify the failures of the processes, through the available technological resources of monitoring and control available. Once this is done, the company values the efficiency and effectiveness of the project, which is essential to keep up with competitors.

From the analysis of the results obtained, it is noted that the project analyzed was divided into four macro areas. Through the indicators, it was possible to verify the quality of the services performed by the workers, compiling the information about quantity of professionals planned, target schedule, actual execution schedule and productivity coefficients.

Furthermore, it was feasible to verify the efficiency of the sectors of the construction work and of the construction work as a whole. In this case, it could see sectors with number of professional overestimated and other underestimated, dates in delay and advanced. Overall, the results point to a misallocation of resource allocation established in planning and budgeting. Leading to a slight imbalance with the physical-financial parameters, in which, once uncorrected, affected in a damaging way the expected profitability of the enterprise.

In this way, it can be concluded that the implementation of the project management methodology within the company in question, makes possible an estimate of the longer term according to the baseline, and a smaller deviation of costs, provided that the methodology is accompanied by agreement with the project life cycle.

Corrêa, H. L., Gianesi, I. G. N., & Caon, M. (2011). Planning, Programming and Production Control: MRPII/ERP, concepts, use and deployment. Atlas.

Corrêa, H. L., & Corrêa, C. A. (2010). Production and Operations Management: Manufacturing and Services: A Strategic Approach. Atlas SA.

Davenport, T. H. (1994). Process reengineering: how to innovate in the company through information technology (Vol. 5). Rio de Janeiro: Campus.

Fernandes, F. C. F., & Godinho Filho, M. (2010). Planning and production control: from fundamentals to essentials.

FIEMG, F. D. I. D. E. (2017). de Minas Gerais. Economic Monitor February 2017, Belo Horizonte, FIEMG.

Fitzsimmons, J. A., & Fitzsimmons, M. J. (2014). Services Administration: Operations, Strategy and Information Technology. AMGH Editora

Forbes, L. H., & Ahmed, S. M. (2011). Modern construction. CRC Press,.

Gaither, N., & Frazier, G. (2001). Production management and operations. Pioneira Thomson Learning.

HARRINGTON, H. J. (1993). Improving Business Processes: A Revolutionary Strategy for Improving Quality, Productivity, and Competitiveness. São Paulo, MakronBooks.

Kagioglou, M., Cooper, R., Aouad, G., & Sexton, M. (2000). Rethinking construction: the generic design and construction process protocol. Engineering, Construction and Architectural Management, 7(2), 141-153.

KRUMENAUER, G. L., & de SOUZA, J. (2016). Planejamento e Controle de Produção (PCP) em uma microempresa do setor calçadista: Um estudo de caso. Revista ESPACIOS| Vol. 37 (Nº 16) Año 2016.

Picchi, F. A. (2003). Opportunities for the application of lean thinking in construction. Ambiente Construído, 3(1), 7-23.

Slack, N., Chambers, S., & Johnston, R. (2009). Production management. Atlas.

Tubino, D. F. (2009). Planning and production control. Atlas.

WOS (2017). Web of Science. Databases of bibliographic information.

1. Studying a Bachelor degree in Industrial Engineering, Pontifícia Universidade Católica de Minas Gerais (PUC Minas), Brazil. E-mail: raphael.foureaux@gmail.com

2. Studying a Bachelor degree in Industrial Engineering, Pontifícia Universidade Católica de Minas Gerais (PUC Minas), Brazil. E-mail: alexandrecarvalhomendonca@gmail.com

3. Master in Industrial Engineering – Universidade Federal de Minas Gerais (UFMG), Bachelor in Industrial Engineering - Universidade Federal de Viçosa (UFV). Tutor of Industrial Engineering Course at Pontifícia Universidade Católica de Minas Gerais (PUC Minas), Brazil. E-mail: andressa@pucminas.br

4. Master in Industrial Engineering - Universidade Federal de Minas Gerais (UFMG), Bachelor in Economics Science from Universidade Federal de Viçosa (UFV). Studying a Bachelor degree in Physics at UFMG. Tutor of Industrial Engineering Course at Centro Universitário Metodista Izabela Hendrix (CEUNIH), Brazil. E-mail: tiago.gontijo@izabelahendrix.edu.br