Vol. 38 (Nº 37) Año 2017. Pág. 22

BRANDÃO, Janaína B. 1; BREITENBACH, Raquel 2; SANTOS, Juliany de O. 3

Recibido: 04/03/2017 • Aprobado: 18/04/2017

RESUMO: Este trabalho verifica as consequências que as divulgações midiáticas de fraudes na cadeia produtiva do leite no Brasil nos anos recentes causaram nas cooperativas ligadas ao beneficiamento deste produto. Constatou-se impacto positivo em relação à comercialização, pois as vendas aumentaram, já que estas não estavam envolvidas em escândalos de adulteração. Mas nas transações para fora do estado houve queda na confiança dos consumidores refletindo numa queda nos preços, o que afeta de maneira negativa todos os elos, incluindo o processador. |

ABSTRACT: This work aimed to verify the consequences that media disclosures of fraud in the milk production chain in Brazil in recent years have caused in the cooperatives linked to the processing of this product. There was a positive impact in relation to commercialization, as sales increased, as they were not involved in adulteration scandals. But in out-of-state transactions, consumer confidence declined, reflecting a drop in prices, which negatively affects all links, including the processor. |

Entende-se por leite, “o produto oriundo da ordenha completa, ininterrupta, em condições de higiene, de vacas sadias, bem alimentadas e descansadas” (Riispoa, 1952). O consumo do leite e seus derivados é importante para o ser humano em todas as fases, pois contém nutrientes essenciais à saúde, como o cálcio e a proteína (Lay-Ang, [201-]). Sendo assim, consumir leite ajuda a manter uma vida saudável evitando doenças como a osteoporose (Abrasso, [201-]).

O consumo per capita de leite no Brasil é de 178 l/pessoa/ano (Altíssimo, 2015), inferior ao recomendado pelo Ministério da Saúde (MS) que é 210 l/pessoa/ano. Já o Rio Grande do Sul (RS) apresenta um consumo acima do nacional, representando 190 l/pessoa/ano, mesmo assim não atingindo a média recomendada pelo MS (Grupo Independente, 2013).

A demanda por lácteos no Brasil cresceu a uma taxa anual de 3% ao longo da última década, incremento favorecido principalmente pelo aumento da renda da população e, também, pela diversificação do portfólio de produtos derivados do leite. O aumento da população urbana e as mudanças no ritmo de vida também impulsionaram o consumo de leite no Brasil (Agroanalysis, 2013).

Da perspectiva produtiva, o Brasil é o quinto colocado no ranking mundial da produção de leite com 36,83 bilhões/l em 2014 sendo que o Rio Grande do Sul (RS) contribui com 4,80 bilhões/l, ficando em segundo lugar no país e perdendo apenas para Minas Gerais que produz 9,54 bilhões/l em 2014 (Sindilat/RS, 2015). Além de ser um alimento importante na alimentação humana, a produção de leite tem relevância na economia do país, pois contribui na geração de empregos e renda. Pacheco (2014) afirma que a cadeia produtiva do leite emprega quatro milhões de trabalhadores somente nas fazendas produtoras no Brasil (Sindilat/RS, 2015).

De acordo com o Sebrae (2010), devido aos avanços tecnológicos e ao conhecimento acumulado, o Brasil deixou de ser importador de lácteos para se tornar autossuficiente, além de exportador. Porém, o destaque no mercado mundial só ocorrerá a partir de um avanço em todos os elos da cadeia, com o aumento da produtividade e da qualidade, bem como fechamento de acordos comerciais com outros países por parte do governo (Silveira, 2015).

No RS 199 mil pessoas estão envolvidas diretamente na atividade de bovinocultura de leite (ZH Campo E Lavoura, 2015). A produção de leite no RS cresceu o dobro nos últimos dez anos (2004/2014) em comparação com a brasileira: 103,39% contra 56,72%, respectivamente (Sindilat, 2015). A produtividade é uma das melhores do Brasil, chegando a 2.430 l/vaca ordenhada por ano (Kirchof, [201-]). Apesar do aumento na produção, muitos produtores estão abandonando a cadeia do leite. De acordo com Colussi (2015) isto está ocorrendo devido à baixa remuneração do trabalho e o aumento dos custos de produção, agravados por falta de pagamento e falência de empresas, algumas envolvidas em fraudes. O autor também afirma que nos últimos cinco anos o RS pode ter perdido mais de 20 mil produtores.

As fraudes destacadas pelo autor se referem, especialmente, ao fato que desde o ano de 2013 no RS, foram descobertas adulterações no leite no qual foram adicionados produtos tais como: soda cáustica, bicarbonato de sódio, água oxigenada, formol entre outros.

Em 2014 o Ministério da Agricultura, Pecuária e Abastecimento (Mapa) procurou tranquilizar os consumidores e garantiu que o leite gaúcho, na maioria, é de qualidade. Entretanto, isso ocorreu depois de representantes do órgão confirmarem que houve fraude nos produtos de duas grandes cooperativas que beneficiam leite no Estado, com a detecção de álcool etílico para mascarar a adição de água no produto. (Kannenberg, 2014). Segundo o diretor do Departamento de Inspeção de Produtos de Origem Animal (DIPOA) do Mapa, Leandro Feijó, 97,4% das análises do leite produzido no Rio Grande do Sul tem índice de conformidade. Ainda segundo o diretor, a média de aprovação gaúcha é maior que a nacional, que é de 96,2%. No entanto, o índice é sobre leite UHT, pasteurizado e em pó, no produto final. As análises que foram detectadas com irregularidade foram sobre leite cru, ou seja, antes de chegar à indústria (Kannenberg, 2014).

Em 2015 o Ministério Público do Rio Grande do Sul deflagrou mais uma fase da Operação ‘Leite Compen$ado’. Em dois anos foram várias etapas de uma ofensiva das autoridades para tentar acabar com uma fraude de adulteração na cadeia de produção do leite no Estado (Freitas, 2015). Considerando a importância do tema coloca-se o seguinte problema de pesquisa: Quais as alternativas estão sendo utilizadas por cooperativas de leite para enfrentar os problemas com as fraudes e/ou adulterações, aprimorar a coordenação da cadeia de suprimentos e recuperar a credibilidade após divulgação de fraudes no leite no RS? Em suma, o presente trabalho teve como objetivo verificar quais as consequências dos ‘escândalos’ relacionados às fraudes no leite para as cooperativas do RS e qual elo da cadeia de suprimentos é mais suscetível às fraudes na perspectiva das cooperativas.

A seguir apresenta-se o referencial teórico que embasou o estudo, a metodologia utilizada na pesquisa e, por fim, os resultados obtidos, indicando as principais conclusões decorrentes da investigação.

A metodologia adotada nesta pesquisa foi o Estudo de Caso. Yin (2005: 32) define o Estudo de Caso como “uma investigação empírica que investiga um fenômeno contemporâneo dentro do seu contexto de vida real, especialmente quando os limites entre o fenômeno e o contexto não estão claramente definidos”. Entretanto, destaca-se que foram realizados três estudos de caso, pois a pesquisa aborda três cooperativas. Tais cooperativas foram escolhidas intencionalmente por trabalharem com a coleta e processamento de leite, não estarem envolvidas em casos de fraude ou adulteração de leite e por estarem representando distintas regiões geográficas do RS, permitindo ter uma visão e conhecimento mais abrangente da realidade do estado.

Destaca-se que o elo focal deste Estudo de Caso, dentro da cadeia produtiva do leite, foram as indústrias de processamento, especificamente as cooperativas. Assim, adota-se o conceito de cadeia de produção como “uma sucessão de operações de transformação dissociáveis, capazes de ser separadas e ligadas entre si por um encadeamento técnico” (Batalha, 2007: 6).

Como técnica de coleta de dados utiliza-se a pesquisa documental e entrevistas em profundidade. A documentação corresponde a toda forma de registro e sistematização de dados, informações, as quais são coletadas para análise por parte do pesquisador (Kauark, Manhães, Medeiros, 2010); a entrevista parte da interação entre pesquisador e pesquisado, sendo uma técnica de coleta de informações com assunto pré-definido (Kauark, et al., 2010). As entrevistas foram realizadas em três cooperativas, sendo realizadas com representantes que tivessem pleno conhecimento dos acontecimentos e temas a serem investigados, sendo nos três casos os gerentes comerciais (três gerentes). As entrevistas ocorreram em outubro de 2015.

Foram realizadas análises qualitativas das informações coletadas nas entrevistas e documentos. Primeiramente descreve-se caso a caso e, num segundo momento, realiza-se a análise comparativa dos casos estudados. Por fim, realiza-se uma análise das consequências das fraudes na cadeia de suprimentos das cooperativas. O nome das cooperativas estudadas não será mencionado no decorrer deste trabalho e serão denominadas de C1, C2 e C3, a sequência é mesma da qual foram feitas as entrevistas.

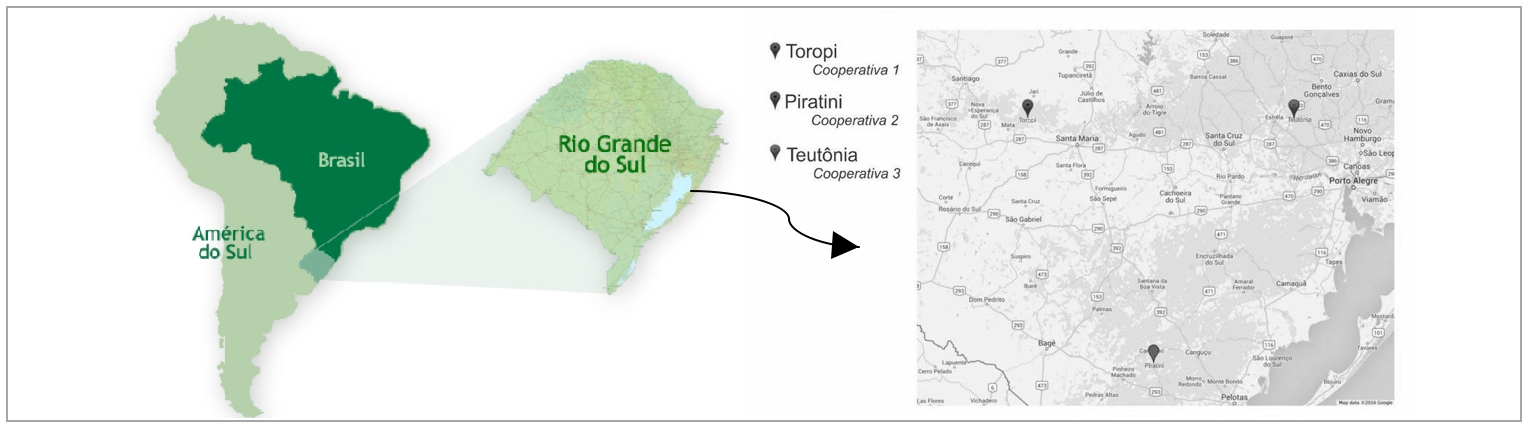

A Figura 1 demonstra a localização das Cooperativas pesquisadas, que foram eleitas porque não se envolveram em nenhum escândalo divulgado na mídia. Inicialmente o intuito do estudo era pesquisar Cooperativas que haviam se envolvido nos problemas divulgados pela mídia. Todavia, depois da negativa das mesmas em colaborar com a pesquisa optou-se por focar em organizações cooperativas não envolvidas nas fraudes, modificando o foco da pesquisa.

Figura 1. Localização geográfica das cooperativas pesquisadas.

Fonte: Elaborado pelos autores com base no Google Maps.

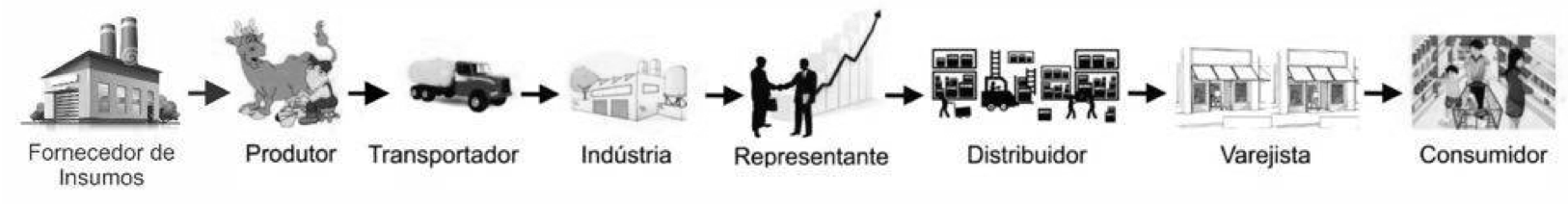

Uma cadeia produtiva é composta por vários elos, que vão desde o produtor de insumos para a produção de leite até o consumidor final. Um conjunto de relações comerciais e financeiras que estabelecem, entre todos os estados de transformação, um fluxo de troca, situado de montante a jusante, entre fornecedores e clientes (Batalha, 2007). De acordo com Viana e Ferras (2007) a cadeia envolve toda a atividade de produção e comercialização de um produto, de forma que, no decorrer da mesma, os produtos são crescentemente elaborados, obtendo agregação de valor. A Figura 2 apresenta de forma ilustrativa uma cadeia produtiva.

Figura 2 - Cadeia produtiva do leite.

Fonte: Adaptada de Canziani (2003).

Dentre os principais representantes da cadeia produtiva do leite, podemos considerar quatro categorias: os fornecedores de insumos, máquinas e equipamentos aos produtores; os produtores rurais, que podem ser divididos em especializados e não especializados; a indústria, a qual influencia significativamente na cadeia, já que tem o papel de coletar o produto junto aos produtores e distribuí-los aos varejistas, supermercados e padarias, os quais são considerados o último elo na categoria deste sistema agroindustrial (Canziani, 2003).

Vários fatores contribuíram para melhor competitividade do produto no Brasil, dentre eles destacam os investimentos em pesquisa, bem como na alimentação dos animais, genética e também em equipamentos específicos para refrigeração do leite e ordenha (Viana e Ferras, 2007).

A qualidade é fundamental nos processos da cadeia de produção e consiste nas características do produto que vão ao encontro das necessidades do cliente e, dessa forma, proporcionam a satisfação (Juran, 1991). A coordenação de qualidade é um conjunto de atividades planejadas e controladas por um agente coordenador, contribuindo para a melhoria da satisfação dos clientes e para a redução dos custos e das perdas em todas as etapas da cadeia. Os benefícios gerados pela prática de coordenação da qualidade incrementam a competitividade da cadeia de produção, seja pela otimização dos recursos aplicados na fabricação de produtos, seja por assegurar a qualidade e segurança dos produtos alimentícios que elabora (Borrás e Toledo, 2006).

No intuito de busca por qualidade e seguir a legislação brasileira a Instrução Normativa 62 (IN 62) foi criada em dezembro de 2011com objetivo de regulamentar a produção, identidade, qualidade, coleta, e transporte do leite tipo A, leite cru refrigerado e leite pasteurizado.

A IN 62 estabelece que o leite deverá ser analisado em laboratórios credenciados para o monitoramento de sua qualidade. A indústria deverá enviar, pelo menos uma vez por mês, amostras do leite de cada produtor para análise em laboratório credenciado na Rede Brasileira de Laboratórios de Controle de Qualidade do leite (RBQL). Os produtores receberão o resultado de suas análises. Com isso, o MAPA vai acompanhar a qualidade do leite em cada propriedade rural, e exigir que os problemas detectados sejam resolvidos. (Dürr, 2012: 25).

De acordo com Dürr (2012) as análises feitas pela RBQL são: contagem bacteriana total (CBT); contagem de células somáticas (CCS); determinação dos teores de gordura, lactose, proteína, sólidos totais, sólidos desengordurados e pesquisa de resíduos de antimicrobianos.

Segundo Santos (2007) o leite deve ser resfriado dentro de duas horas após a ordenha para a temperatura de aproximadamente 4°C. Esse resfriamento é fundamental para garantir que não haja a proliferação de microrganismos garantindo assim um manejo adequado visando à qualidade do produto final. O transporte desse leite também é importante, pois “o leite cru refrigerado deverá ser transportado a granel da propriedade para a indústria, em tanques rodoviários isotérmicos” (Sebrae, 2010: 24). Ao chegar ao destino, ao ser recebido na plataforma de recepção, é submetido a algumas análises preliminares antes de ser liberado para seguir no fluxo da linha de produção dentro do laticínio (Silva; Silva; Ferreira, 2010).

A próxima etapa é a de padronização do produto, “o principal objetivo da padronização do leite é a obtenção de um produto com composição química definida, a qual atenda aos requisitos básicos para elaboração de diversos produtos lácteos” (Silva et al., 2012: 68). O próximo passo é de pasteurização que consiste em submeter o leite a um nível de aquecimento onde todos os microrganismos patogênicos presentes neste alimento sejam destruídos (Meldau, 2015).

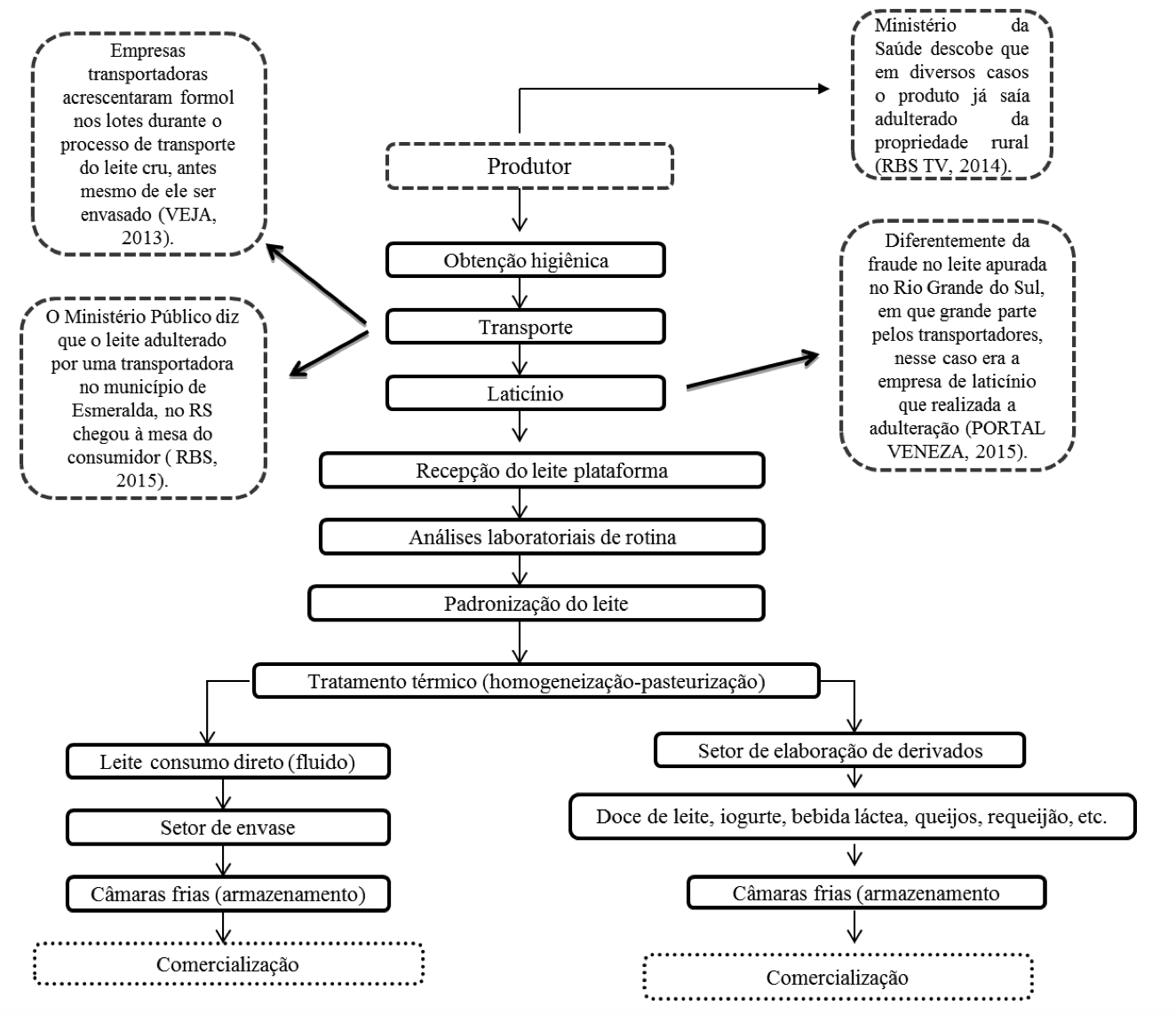

A Figura 3 esquematiza esse processo e problematiza algumas etapas. Para melhor entendimento, foi incluído o elo produtor e destacados os elos em que já ocorreram denúncias na mídia sobre a adulteração do leite que são: produtor, transporte e indústria.

Figura 3 - Fluxo do leite na indústria com destaque dos elos onde pode ocorrer a adulteração.

Fonte: Adaptada de Silva, Silva e Ferreira (2012).

Diante da complexidade exposta na Figura 2, pondera-se que o encadeamento das diferentes etapas resulta da ação de diferentes elos e exige confiança entre as partes para que a cadeia de suprimentos funcione adequadamente.

O conceito de cadeia de suprimento teve sua origem na logística, onde inicialmente a ênfase era dada à facilitação da movimentação de materiais e coordenação da demanda entre fornecedor e cliente (Borrás e Toledo, 2006). Atualmente, o conceito de gestão da cadeia de suprimentos está relacionando-se a outros conceitos como parcerias, alianças estratégicas e outras relações cooperativas entre os membros da cadeia de suprimento, resultando em aumento da ênfase dada aos fatores transacionais nela presentes (Borrás e Toledo, 2006). Existem diversas definições de Gerenciamento da Cadeia de Suprimentos (GCS), praticamente todas complementares e concebidas sob a perspectiva de seus autores (Pires, 2010).

Dentro da cadeia de suprimentos as cooperativas podem assumir um papel peculiar, pois atendem melhor as necessidades dos agricultores/fornecedores, já que o elo processador é representado organizacionalmente pelos próprios agricultores/fornecedores, aproximando os elos ‘produtor x indústria’.

O cenário cooperativista do mundo demonstra potencial e alcance do setor cada vez maior; antes como instituições pequenas e simples, hoje as cooperativas modernizam e figuram como instituições fortes que geram renda e impulsionam o desenvolvimento do planeta; o setor já está presente nos cinco continentes, reúne um bilhão de pessoas em mais de 100 países e gera mais de 100 milhões de empregos (Menezes, 2012).

De acordo com o relatório da Organização das Cooperativas do Brasil 46 milhões de brasileiros estão envolvidos no cooperativismo e 11,5 milhões estão ligados de forma direta a uma das 6,8 mil cooperativas atuantes no país nos diferentes ramos (OCB, 2014). Em 2014 5,3 bilhões foi o volume de exportações por cooperativas brasileiras, entre 2004 e 2013 houve um crescimento de 87,9% no número de cooperados no Brasil e um crescimento de 83,2% no número de empregos gerados por cooperativas. (Relatório OCB, 2014). Desde 2002 a força de trabalho das cooperativas, quase dobrou, passando de 171,3 mil empregados para 340 mil; o ramo agropecuário é o que mais gera empregos diretos: 164,2 mil (51%), em seguida, aparecem às cooperativas de saúde (78,2 mil) e crédito (38,1 mil) (Portal Do Cooperativismo Financeiro, 2015). O número de cooperativas no ramo agropecuário é de 1.561 e o total de empregos diretos gerados por essas cooperativas é de 164.223 (Dias Junior, 2013).

Cabe destacar que o foco desta pesquisa é apenas o ramo agropecuário, que “reúne produtores rurais, agropastoris e de pesca que detêm os próprios meios de produção (Relatório OCB, 2014: 16). Este “é um dos ramos com maior número de cooperativas e associados no Brasil, e o leque de atividades econômicas, abrangidas por esse ramo é enorme e sua participação no PIB é significativa.” (SESCOOP, 2007: 34).

As cooperativas de produção formam o ramo economicamente mais forte do cooperativismo brasileiro; é o ramo cooperativo de maior expressão numérica em todo o mundo, mais de 50% das cooperativas são de produtores agropecuários, abrangendo todas as atividades econômicas do setor primário (SALES, 2011). A atuação da cooperativa abrange três estágios do setor agropecuário: antes, durante e após o processo produtivo; essa atuação é importante, inicialmente, para o fornecimento de bens de produção: sementes, fertilizantes, mecanização, planejamento, e distribuição dos insumos; assegura-se durante a fase produtiva, assistência técnica, controle integrado e aplicação de insumos e na pós-colheita, serviços de recebimento, de limpeza, de classificação, de acondicionamento e de armazenamento bem como a agroindustrialização, a comercialização e exportação dos produtos (SALES, 2011).

A importância das cooperativas gaúchas pode ser evidenciada pelo fato de que em 2014 o governo do estado assinou um documento que dá origem a uma plataforma de negócios entre o RS e a China, através de quatro cooperativas gaúchas. O acordo visa respaldar a entrada de empresas gaúchas no mercado chinês, principalmente na zona de livre comércio de Xangai, através de medidas prática como identificação de produtos, certificação e exposição (Revista Leite e Derivados, 2014). O que fortalece a importância das cooperativas e sua contribuição no setor da cadeia produtiva do leite.

Entretanto, faz-se necessário destacar as especificidades das cooperativas, tanto do ponto de vista conceitual quanto operacional. Uma cooperativa se diferencia de outros tipos de associações por seu caráter essencialmente econômico. A sua finalidade é colocar os produtores e serviços de seus cooperados no mercado, em condições mais vantajosas do que eles teriam isoladamente (Sebrae, Cooperativa, 2009: 9).

Já Batalha (2007: 711) define uma cooperativa como “organizações entre economias particulares dos cooperados, de um lado, e o mercado, de outro, aparecendo como estruturas intermediárias, formadas em comum”. As cooperativas não irão possuir, do ponto de vista econômico, uma existência autônoma e independente dos seus membros, como ocorre na sociedade de capital, mas deverão existir como organização econômica intermediária, posta a serviço da satisfação das necessidades das economias particulares dos cooperados (Batalha, 2007).

Assim, “... o cooperativismo apresenta, para o produtor rural, uma grande vantagem, uma vez que esta forma de organização comprovadamente aumenta seu nível de renda, apresentando-se, portanto, como uma empresa altamente interessante” (Batalha, 2007: 730).

Conforme Batalha (2007) a dificuldade de negócio é a própria doutrina do cooperativismo quanto à inexistência do lucro, levando a uma situação em que poderá existir uma tendência de maximização do ganho isolado do produtor, e não de sua cooperativa, o que pode resultar em dificuldades financeiras e administrativas. Isto porque de um lado o produtor é o ‘dono’ da cooperativa, mas de outro, pode ser visto como fornecedor, que deseja a otimização do seu produto individual, gerando uma complexidade nas relações estabelecidas.

Esse aspecto (relacionado ao fato do produtor ser o ‘dono’) leva a crer na hipótese de que deve haver maior confiabilidade ao longo da cadeia, o que resultaria em maior segurança para o consumidor. O que não põe em dúvida os rigorosos mecanismos de controle que existem (via de regra) nas demais empresas privadas, relacionando-se apenas a um suposto nível de comprometimento dos fornecedores (no caso os produtores).

Primeiramente apresenta-se uma descrição dos casos, mapeando os elos que fazem parte da cadeia produtiva, identificando o comprimento do canal de comercialização e apontando qual destes é considerado o mais crítico em termos de risco de adulteração/fraude nas realidades estudadas. Após faz-se uma breve sistematização dos casos. No segundo item são apontados os impactos na comercialização e mecanismos de prevenção adotados, identificando o objetivo da organização para o futuro da cooperativa, traçando perspectivas para a cadeia produtiva em que estão inseridas.

A cooperativa denominada Cooperativa 1 (C1) caracteriza-se como uma cooperativa de produção mista fundada em 1964 e comercializa o produto dos seus associados, agricultores familiares da região. A sede da C1 fica na cidade de Toropi/RS na região central do estado, a 357 (quilômetros) km de Porto Alegre. Sua área abrange os municípios de São Gabriel, Júlio de Castilhos, Tupanciretã, Jari, São Martinho da Serra, Quevedos e Dilermando de Aguiar. Possui ainda duas filiais em São Pedro do Sul.

No momento de realização da pesquisa estava com 3.250 associados, sendo que 255 trabalham com a atividade produtiva do leite. Além do leite, a cooperativa trabalha com: milho; soja; feijão; trigo e arroz (foco principal). Está atuando no mercado de laticínios com recebimento e resfriamento desde 1983 (há 32 anos), atualmente recebem uma média de 6.200.000 litros/ ano e este produto é vendido in natura para uma empresa que fica localizada em Ijuí e na própria cidade sede da C1.

Dentro da cadeia de suprimentos, a C1apenas faz a coleta do leite com os agricultores/fornecedores que são seus associados e armazena nas condições adequadas para ser vendido para uma indústria que será a responsável pelo restante do processo e, com isso, a C1 não tem mais ligação direta com os outros elos da cadeia, visto que sua função é apenas refrigerar o leite. Segundo a C1, o risco de ocorrer a adulteração do leite são equivalentes em todos os elos, ou seja: produtor; transportador e indústria.

A Cooperativa 2 (C2) é uma cooperativa de produção mista, localizada na cidade de Piratini/RS à 347 quilômetros de Porto Alegre. Foi fundada por assentados da reforma agrária em 1995, em que vinte e três associados faziam parte do grupo coletivo.

Quando da realização da pesquisa, a C2 possuía 53 associados, todos trabalhando com a bovinocultura de leite. Os associados responsáveis pela produção de leite são: 1- Treze produtores que trabalham de forma individual e 2 – o restante são produtores que optam pela produção coletiva. Na produção coletiva os animais são ordenhados diretamente na C2.

Faz dez anos que beneficia o leite no local e no momento industrializa leite pasteurizado e queijo, este último comercializado informalmente. A comercialização do leite tipo C é feita através da venda para os mercados locais de três municípios: Piratini; Candiota e Pinheiro Machado. A distribuição é feita também para o Programa Nacional de Alimentação Escolar (PENAE) dos municípios de Piratini e Candiota e para o Programa de Aquisição de Alimentos (PAA) em vários locais. No que se refere à venda para o varejo, são comercializados os produtos em lojas da região e da própria cidade sede.

A média de produção varia entre 30 e 35 mil litros de leite beneficiado/mês. Quando a produção extrapola esse valor, o excedente é vendido para outra cooperativa.

A Cooperativa 3 (C3) é caracterizada como cooperativa de produção mista, que atua em vários seguimentos, quais sejam: laticínios, aves e suínos, embutidos, rações e varejo (supermercado e loja agropecuária). A C3 fica no município de Teutônia, distante 100 quilômetros de Porto Alegre. Dispõe dos próprios supermercados que ficam localizados nos municípios de Teutônia, Poço das Antas e Bom Retiro do Sul. Também possui lojas de produtos agroveterinários, no município de Cruzeiro do Sul e Teutônia. Quando da realização da pesquisa possuía 6.100 associados sendo que destes 1.700 são produtores de leite. Fundada em 1955, atua no setor de lácteos desde 2005, quando ocorreu a construção da indústria de laticínios e iniciou com a transformação de 140 mil litros de leite por dia. Quando da realização da pesquisa produziam 480 mil litros de leite/dia (e todo leite coletado é oriundo apenas dos associados).

No laticínio ocorre a produção de leite longa vida (UHT), leite pasteurizado e derivado como o iogurte; doce de leite; requeijão e nata, também há a terceirização para a fabricação de queijo e leite em pó. A comercialização destes produtos é feita através das nove centrais de distribuição no estado, onde recebem a mercadoria de todas as plantas (aves, suínos, embutidos, laticínios, rações e varejos) e redistribui para o varejo de diferentes portes. Fora do estado possuem uma central em Santa Catarina, onde ocorre também à venda para grandes redes.

A partir do exposto tem-se que os casos escolhidos caracterizam-se por cooperativas distintas, tanto pelos aspectos organizacionais (escala de produção, número de associados, etc.) quanto pela forma de comercialização adotada. Para melhor visualização dos elementos gerais das cooperativas pesquisadas, os principais dados obtidos estão descritos no Quadro 1.

Quadro 1– Síntese das cooperativas estudadas.

Característica |

Cooperativa 1 |

Cooperativa 2 |

Cooperativa 3 |

Tempo atuação na área de laticínios |

32 anos |

10 anos |

10 anos |

Número de Associados |

3.250 |

53 |

6.100 |

Número de associados que trabalham com leite |

255 |

53 |

1.700 |

Volume leite |

516.66 l/mês |

30-35 mil l/mês |

14.400 mil l/mês |

Produtos (relacionados ao leite) |

Leite resfriado |

Leite tipo C pasteurizado, queijo. |

Leite UHT, iogurte, doce de leite, requeijão, queijo, nata e leite em pó. |

Comercialização |

Empresa privada |

Varejo local |

Varejo regional e nacional |

Produção principal |

Arroz |

Leite tipo C pasteurizado |

Leite UHT (longa vida) |

Transporte |

Próprio |

Próprio |

Próprio |

Fonte: Elaborado pelos autores com base nos dados da pesquisa.

Dos três casos estudados, a C1 é a que está a mais tempo no mercado, a C2 e C3 ambas estão atuando a dez anos negócio. Nota-se que na C1, do total de associados, apenas 7,8% trabalham com o leite, fornecendo em média para a cooperativa 2 mil l/mês. Na C2 100% dos associados estão envolvidos na atividade principal, e cada associado contribui em média com 700 l/mês. Já na C3, do total dos associados, 27,8% trabalha com a produção de leite, ofertando uma média 8,5 mil l/mês.

Quanto à comercialização, a C1 fornece para uma empresa privada e a C2 somente para o varejo local. Apenas a C3 abastece o varejo nacional, que é realizado através da central de distribuição localizada em Santa Catariana. Nota-se também, que as três cooperativas possuem transporte próprio, buscando que ocorra o comprometimento do transportador com a organização.

Quando ocorrem divulgações de fraudes no leite, toda a cadeia fica fragilizada, não apenas aquele elo que sofreu adulteração, mas todos aqueles que compõem a cadeia produtiva e, de forma particular, a cadeia de suprimentos das indústrias. Esses problemas causam insegurança ao consumidor, a credibilidade se rompe, já que nem a legislação nem as ‘superestruturas’ conseguem garantir a idoneidade do produto final.

Conforme as informações obtidas pela pesquisa, as divulgações feitas pela mídia sobre fraudes no leite causaram nas cooperativas impactos positivos e negativos, ao mesmo tempo, como descrito no Quadro 2.

Quadro 2 - Cenário das cooperativas em relação aos impactos e vendas.

Variáveis |

Cooperativa 1 |

Cooperativa 2 |

Cooperativa 3 |

Impactos |

Negativos |

Positivos e negativos |

Positivos e negativos |

Vendas |

Diminuíram |

Aumentaram |

Aumentaram |

Fonte: Elaborado pelos autores com base nos dados da pesquisa.

Conforme se observa no Quadro 2 os impactos negativos foram sentidos nas três cooperativas. A C1 se sentiu prejudicada em relação aos preços, já que ocorreu queda no valor recebido pelo leite in natura. Já a C2 e C3 saíram lesados devido à perda de confiança dos consumidores. Por outro lado, após as fraudes, houve um aumento nas vendas das C2 e C3 dentro do estado, sendo que a C2 aumentou 30% a quantidade comercializada. Isso se justifica pelo fato destas cooperativas não estarem envolvidas em escândalos de adulteração. Já para a C1 os impactos causados na comercialização foram considerados apenas negativos, pois teve queda no valor pago pelo leite in natura, consequência da redução no consumo (lembrando que a C1 atua como posto de recebimento e resfriamento).

É consenso nas cooperativas estudadas que os principais elos em que pode ocorrer a fraude são: produtores; transportadores e nas próprias indústrias.

Para evitar que episódios de fraude e/ou adulterações venham acontecer dentro da organização, a C1 intensificou o treinamento dos produtores e transportadores para garantir a qualidade do leite. A C2 realiza reuniões periódicas para conscientizar os produtores da importância da qualidade do produto, também é feita análise do leite na propriedade e quando chega à cooperativa. A C3 também faz análises do produto e dá uma bonificação ao produtor pela qualidade do leite. Em todos os casos percebe-se uma intensificação na sensibilização dos produtores, através de capacitação ou recompensa, isto ocorre com objetivo de conscientizá-los da necessidade da qualidade do leite. Todas essas ações demonstram que o relacionamento com o fornecedor foi aprofundado, reforçando os laços dentro da cadeia de suprimentos.

Quanto às ações para reduzir os impactos negativos das fraudes, a C1, por ser um posto de recebimento e resfriamento, não utiliza nenhuma, pois não tem contato com o consumidor final. A C2 utiliza do marketing “boca a boca”, o que se torna mais fácil pelo fato deles mesmos fazerem a entrega do produto ao consumidor. A C3 não dispõe de propagandas para intensificar a venda dos produtos. Em nenhum dos casos ocorrem iniciativas para incentivar o consumo do leite e derivados, o marketing é apenas para aumentar as vendas.

Os três casos estudados possuem seu próprio transportador, sendo assim, supõe-se que há uma tendência de verticalização do transporte. Desta forma, sustenta-se que as organizações estão ‘investindo’ neste elo para evitar fraudes durante o deslocamento do produto, evitando fontes de incerteza. Portanto, esse fator foi visualizado como um dos mais importantes para a prevenção das fraudes nos casos estudados.

O presidente do Sistema de Organizações Cooperativas do Brasil (2015) durante a abertura do 2° Encontro Pan-Americano de Jovens Produtores de Leite afirmou que o futuro da produção leiteira está intimamente ligado ao cooperativismo (OCB, 2015). Diante disto, percebe-se a importância das cooperativas no futuro do desenvolvimento da cadeia produtiva do leite. Dessa forma, destaca-se que nos três casos estudados não foram verificados problemas com adulteração.

Pondera-se como fator explicativo, o fato de poder haver o comprometimento dos fornecedores, que também são os ‘donos’ das unidades de beneficiamento, organizadas juridicamente na forma de cooperativas, o que garantiria maior confiabilidade e segurança ao longo da cadeia de suprimentos, representada pelo compromisso dos agricultores/fornecedores.

Visando melhorar a qualidade do produto, vê-se um esforço do Ministério da Agricultura, Pecuária e Abastecimento para atualizar e adequar as legislações do setor com vistas a garantir a qualidade dos produtos e a saúde pública, (por exemplo, o Regulamento Técnico de Identidade e Qualidade dos Produtos Lácteos, do MAPA (2015). Entretanto, após os escândalos observa-se que persiste a desconfiança por parte dos consumidores, já que a imagem dos laticínios e dos transportadores ficou prejudicada após a operação judicial que investigou, descobriu e deflagrou fraudes na cadeia produtiva do leite (BREITENBACH; TRINDADE, 2015).

Numa pesquisa realizada com consumidores de todo Brasil constata-se que as fraudes resultaram em consequências negativas que impactam todos os agentes (BREITENBACH; TRINDADE, 2015). Os resultados da pesquisa também indicaram que os consumidores passaram a escolher melhor as marcas de leite no varejo. Portanto, a redução no consumo se concentra em maior grau naquelas marcas relacionadas às empresas que tiveram fraudes identificadas e divulgadas na mídia (BREITENBACH2; TRINDADE, 2015). Isso foi corroborado pelo presente estudo, já que, para além dos efeitos negativos, as cooperativas estudadas sentiram também impactos positivos, porque seus nomes não estavam envolvidos nos escândalos, resultando em reforço da confiança do consumidor em relação as suas marcas.

Por fim, apesar das denúncias comprovadas, que envolveram pelo menos duas grandes cooperativas lácteas do RS, alerta-se para a importância das organizações cooperativas no setor leiteiro. Estas historicamente contribuíram para o desenvolvimento da atividade, atuando na produção, agroindustrialização e comercialização do produto.

Do ponto de vista prático, os casos divulgados na mídia e mencionados anteriormente são graves porque afetam a qualidade de um alimento que é caracterizado pelo consumo de lactantes e crianças, o que torna ainda mais crítico do ponto de vista da segurança alimentar e saúde humana. Constata-se que existiu falha no controle sanitário, especialmente no recebimento da matéria-prima. Demonstrando que mesmo estando com estrutura física adequada e de acordo com a legislação as agroindústrias não garantem ao consumidor a confiabilidade esperada. Observa-se falta de controle por parte do Estado, que não cumpre seu papel em fiscalizar a qualidade, já que para além das questões materiais são necessários controles de processo e relações que elevem o nível de confiança ao longo da cadeia.

Desde o nível teórico, não se pode furtar de trazer à tona lições mais abrangentes, especialmente uma reflexão sobre os temas segurança alimentar e confiança entre os agentes ao longo da cadeia. Nesse sentido, cabe ressaltar que a responsabilidade pela segurança alimentar do consumidor é de todos os agentes da cadeia produtiva, e se um deles falhar, todo processo fica comprometido. É o que ocorreu nesses episódios de fraude, já que nos casos investigados foram condenados alguns agentes da cadeia, mas todos são prejudicados em maior ou menos grau. E, ainda, o consumidor final que é o principal foco da produção, pode ter a segurança alimentar comprometida.

Além disto, considera-se relevante fazer algumas considerações sobre o perfil do consumidor brasileiro de leite. Embora se discuta recentemente que o consumidor de alimentos tem elevado suas exigências, de um modo geral ainda é pouco observador e sensível a produtos e organizações diferenciadas. É o que fica visível quando as pesquisas apontam que o preço continua sendo o principal fator de decisão na hora da compra do leite pelo consumidor. Isso pode ajudar explicar que o fato das cooperativas não estarem envolvidas nos escândalos não trouxe vantagens substanciais fora da região onde atuam. Ou seja, o público consumidor não tem “maturidade” de consumo para identificar a origem do leite como vindo de empresas ou de cooperativas.

Por fim, destaca-se que o enfraquecimento do sistema cooperativo perante os desafios cooperativos num agronegócio competitivo e concorrencial, apontam para a dificuldade das cooperativas se fortalecerem enquanto tal. Ou seja, o fato de serem cooperativas e terem associados como fornecedores de matéria prima, por si só, não diminuem consideravelmente as chances de sofrer este tipo de escândalos, em comparação com as empresas. Para que isso ocorra, é necessário que as cooperativas estabeleçam mecanismos de controle da produção ao longo da cadeia da mesma forma que as empresas privadas. Portanto, a confiança entre agentes não demonstra ser maior nas cadeias de suprimentos gerenciadas em organizações cooperativas do que em organizações privadas, mostrando que nestas duas formas de organização este aspecto merece ser desenvolvido e melhorado especialmente quando se fala em cadeia produtiva do leite.

O objetivo da presente pesquisa foi verificar quais as consequências dos ‘escândalos’ relacionados às fraudes no leite para três cooperativas do RS e identificar qual elo da cadeia de suprimentos está mais suscetível às fraudes/adulterações na perspectiva das cooperativas. Constatou-se que o setor cooperativo, considerada suas características descritas nesse trabalho, passou por esse processo com prejuízos, mas merece destaque que não foram todas as organizações cooperativas prejudicadas já que muitas não se envolveram em processos judiciais, como os casos pesquisados.

Isso ocorre já que essas organizações não tiveram problemas de fraude nas cadeias de suprimento que fazem parte, bem como não tiveram exposição negativa de suas marcas e nomes na mídia. Nesse contexto, reforçaram sua imagem positiva perante os consumidores, especialmente se comparado a outras organizações que, estando envolvidas em processos fraudulentos, perderam credibilidade.

Entretanto, observou-se que se as cooperativas por um lado tiveram aumento nas vendas, por outro, tiveram sua imagem prejudicada fora do estado, pois o consumidor ficou com receio em comprar produtos que tenham sido produzidos no RS, pela dificuldade dos consumidores em identificar e memorizar especificamente as organizações que estiveram envolvidos nos escândalos.

Visando evitar problemas futuros, as cooperativas – especialmente as que fazem o processamento do produto - estão focando e investindo em dois elos da cadeia: transportador e produtor. Acreditam que através da verticalização do transporte podem diminuir as incertezas na cadeia, já que passam a ter maior controle do processo. Já acerca do produtor, o foco é na sensibilização e comprometimento dos mesmos, além da capacitação e, ainda, o pagamento por qualidade do produto.

Compreende-se que um terceiro agente deveria receber atenção especial das organizações, que são os consumidores. Estes comprovadamente têm memória curta acerca de marcas e organizações quando envolvidas em algum processo fraudulento. Nesse sentido, acabam generalizando negativamente o leite em nível de estado, sendo que são pontuais os casos de adulteração, estando as cooperativas estudadas livres de qualquer envolvimento. Neste caso, campanhas promocionais, propagandas e marketing de modo geral, no sentido de promover o produto e mostrar essa realidade, além de apresentar a importância do leite e derivados para a saúde humana, seriam fundamentais para o crescimento do setor.

ABRASSO. Associação Brasileira de Avaliação Óssea e Osteometabolismo.Osteoporose atinge 10 milhões de brasileiros. 2015. Acessado em 14/05/2016. Obtido em: http://abrasso.org.br/noticia/abrasso-alerta-sobre-riscos-da-osteoporose-doenca-que-atinge-10-milhoes-de-brasileiros

AGROANALYSIS. Será um ano de recuperação. 2013. Obtido em: http://www.agroanalysis.com.br/6/2013/mercado-negocios/setor-leiteiro-2013-sera-um-ano-de-recuperacao

ALTÍSSIMO, Fabiano. Produção de leite cresce e país passará a exportar mais do que importar. FETRAF-sul. 2015. Obtido em: http://www.fetrafsul.org.br/index.php?option=com_content&view=article&id=3041:producao-de-leite-cresce-e-pais-passara-a-exportar-mais-do-que-importar&catid=1:ultimas-noticias&Itemid=104

BATALHA, Mário O. Gestão Agroindustrial. Coord. Batalha, M. O. 3. Ed. São Paulo: Atlas. 2013

BORRÁS, Miguel Á.l A.; TOLEDO, J. C. de Agronegócios: gestão e inovação. Org. Zuin, Luís F. S.; Queiroz, Timóteo R. São Paulo: Saraiva. 2006

BREITENBACH, Raquel.; TRINDADE, Frederico Dos S. Fraudes do leite e imagem do setor: quais agentes o consumidor responsabiliza e em quem ele confia?. Simpósio do Leite. Anais... Erechim. 2015

RISPOA, Brasil. Lei Nº 5.764, de 16 de dezembro de 1971.. Obtido em: http://www.planalto.gov.br/ccivil_03/Leis/L5764.htm

CANZIANI, José R. F. Programa Empreendedor Rural. Cadeias Agroindustriais. Curitiba: SENAR.PR. 2003

COLUSSI, Joana. Pode ter perdido mais de 20 mil produtores de leite em cinco anos, estima FETAG Zero Hora. RS. 2015. Obtido em: http://zh.clicrbs.com.br/rs/noticia/2015/05/rs-pode-ter-perdido-mais-de-20-mil-produtores-de-leite-em-cinco-anos-estima-fetag-4768035.html

DIÁRIO DE SANTA MARIA. Empresário é Denunciado por Adulterar Leite, diz Ministério Público. 2014. Obtido em: http://diariodesantamaria.clicrbs.com.br/rs/noticia/2014/03/empresario-e-denunciado-por-adulterar-leite-diz-o-ministerio-publico-4455553.html

DIAS JUNIOR, Paulo Cr. Cooperativismo Agropecuário. Câmara Temática de Insumos Agropecuários. 2015 Brasília, 25 de novembro de 2013. Obtido em: http://www.agricultura.gov.br/arq_editor/file/camaras_tematicas/Insumos_agropecuarios/71RO/app_ocb

DÜRR, João W. Como produzir leite de qualidade 4. ed. Brasília: SENAR, 2012. Obtido em: http://www.agricultura.gov.br/arq_editor/file/CRC/SENAR%20-%20Produ%C3%A7%C3%A3o%20de%20leite%20conforme%20IN%2062.pdf

FREITAS, Caetano. MP flagra leite azedo e faz nova operação contra transportadora e cooperativa. Zero Hora. 2015. Obtido em: http://zh.clicrbs.com.br/rs/noticias/noticia/2015/05/mp-flagra-leite-azedo-e-faz-nova-operacao-contra-transportadora-e-cooperativa-4759677.html

GRUPO INDEPENDENTE. 5º Maior Produtor, Brasil Não Consome Leite Suficiente. 2013. Obtido em: http://www.independente.com.br/5o-maior-produtor-brasil-nao-consome-leite-suficiente.html

JURAN, Joseph M. Controle da Qualidade. Trad. de Maria Cláudia de Oliveira Santos. São Paulo: Makron, Mc Graw – Hill, 1991.

KAUARK, Fabiana da S.; MANHÃES, Fernanda C.; MEDEIROS, Carlos Henrique. Metodologia da pesquisa. Um guia prático. Bahia, 2010. Obtido em: http://www.pgcl.uenf.br/2013/download/livrodemetodologiadapesquisa2010.pdf

KIRCHOF, Breno. Bovinos de leite. ([201-]. Obtido em: http://www.emater.tche.br/site/area-tecnica/sistema-de-producao-animal/bovinos-de-leite.php#.VhCP49yDGko> [201-]. Acesso em: 03 out. 2015.

LAY-ANG, Giorgia. A importância do leite para a saúde. Brasil Escola. 2015. Obtido em: http://www.brasilescola.com/saude/a-importancia-leite-para-saude.htm.

MELDAU, Débora C. Pasteurização. 2015. Obtido em: http://www.infoescola.com/microbiologia/pasteurizacao/

PACHECO, Weverton F.; ARRUDA, Paulo César L. de; CARMO, Anna Beatriz R. do; LIMA, Francisco W. R. Um estudo sobre a organização da cadeia do leite e análise de rentabilidade de uma fazenda com opções de comercialização de queijo ou leite. Revista Razão Contábil & Finanças. 2014 Obtido em: http://institutoateneu.com.br/ojs/index.php/RRCF/article/view/30

SANTOS, Marcos V. Padrões mínimos de qualidade do leite: é necessária uma nova revisão de IN 62? 2007. Obtido em: http://www.milkpoint.com.br/mypoint/6239/p_padroes_minimos_de_qualidade_do_leite_e_necessaria_uma_nova_revisao_da_in_62_5597>.aspx

SEBRAE. A união que faz a diferença. N° 17, DEZ. 2010, P. 12. Obtido em: HTTP://201.2.114.147/BDS/BDS.NSF/C27EFC1D47AAEFC78325786F0044B33A/$FILE/NT00045502.PDF. Acesso em: 04 OUT. 2015.

SILVA, Gilvan; SILVA, Argélia M. A. D.; FERREIRA, Maria P. B.; Produção alimentícia. Processamento de leite. E-Tec Brasil. 2010. Obtido em:http://200.17.98.44/pronatec/wpontent/uploads/2013/06/Processamento_de_Leite.pdf

SILVEIRA, Leandro. Navegando contra o vento. Revista Leite & Derivados. N° 156, ano XXII, agosto. p. 26. 2015

SINDILAT/RS. Sindilat/Rs Vai à Russia Negociar Exportações de Lácteos. 2015. Obtido em: http://www.sindilat.com.br/index.php/noticias/432-sindilat-rs-vai-a-russia-negociar-exportacao-de-lacteos. 2015

VIANA, Giomar; FERRAS, Robson P. R. Um estudo sobre a organização da cadeia produtiva do leite e sua importância para o desenvolvimento regional. Revista Capital Científico do Setor de Ciências Sociais Aplicadas v. 5, n. 1, 2007. Obtido em:http://www.spell.org.br/documentos/download/32980

KANNENBERG, Vanessa. Após fraude de cooperativas, agricultura cobra mais rigor em análises do leite. Zero Hora. 2014. Obtido em:http://zh.clicrbs.com.br/rs/noticias/noticia/2014/08/apos-fraude-de-cooperativas-agricultura-cobra-mais-rigor-em-analises-do-leite-4572579.html

Yin, Robert. K. Estudo de Caso. Planejamento e Métodos. Porto Alegre: Bookman. 2005.

ZERO HORA. Operação coíbe adulteração de leite no norte do RS. 2013. Obtidoem:HTTP://ZH.CLICRBS.COM.BR/RS/NOTICIAS/ECONOMIA/NOTICIA/2013/05/OPERACAO-COIBE-ADULTERACAO-DE-LEITE-NO-NORTE-DO-RS-4130792.HTML

ZH CAMPO E LAVOURA. O mapa da produção de leite no RS. 2015. Obtida em: http://zh.clicrbs.com.br/rs/noticias/campo-e-lavoura/noticia/2015/05/gisele-loeblein-o-mapa-da-producao-de-leite-no-rs-4770589.html

1. Mestre e doutora em Extensão Rural. Professora do Programa de Pós Graduação em Extensão Rural da Universidade Federal de Santa Maria. E-mail: janainabalkbrandao@gmail.com

2. Mestre e doutora em Extensão Rural. Professora do Instituto Federal do Rio Grande do Sul. E-mail: raquel.breitenbach@sertao.ifrs.edu.br

3. Zootecnista. E-mail: juliany_docouto@hotmail.com