Vol. 38 (Nº 22) Año 2017. Pág. 38

Isis Gonçalves de TOLEDO Alexandre 1; André Valdir da SILVA 2; Alvaro Guillermo Rojas LEZANA 3; Mauricio Uriona MALDONADO 4; Fernando Antônio FORCELLINI 5

Recibido: 18/10/16 • Aprobado: 29/11/2016

2. Business process management

ABSTRACT: The present article aims at reviewing and assessing suppliers’ development process of a manufacturing plant, identifying processes, current models, analysis and process redesigning using business process management methodology. The use of BPM tools optimizes procurement main role and contributes to development process lead time reduction around 40% and 56%, besides seeking alternative suppliers and materials, thereby meeting organizations needs regarding delivery warrantee and profitability. |

RESUMEN: El presente artículo tiene como objetivo examinar y evaluar los procesos de desarrollo de los proveedores de una planta de fabricación, la identificación de procesos, modelos actuales, análisis y rediseño de procesos utilizando la metodología de gestión de procesos de negocio. El uso de herramientas de BPM optimiza la función principal de adquisiciones y contribuye al proceso de desarrollo de reducción de tiempo de espera alrededor de un 40% y un 56%, además de buscar proveedores y materiales alternativos, respondiendo así a las organizaciones con relación a las necesidades de garantía de entrega y la rentabilidad. |

Supplier relationship management (SRM) plays a key role in the overall performance of manufacturing organizations by providing the structure for how relationships with suppliers will be developed and maintained (Lambert and Schwieterman, 2012).

According to these authors, management identifies those suppliers and supplier groups to be targeted as part of the firm’s business mission. The supplier relationship management teams work with key suppliers in order to tailor product and service agreements (PSAs) and to meet the organization’s needs, as well as those of the selected suppliers.

While the supply chain activities among different companies enables specialisation and economies of scale, many critical issues and problems need to be solved for successful supply chain operations (Trkman et al., 2007).

Research shows that SRM might impact revenues in about 50%, which demands systematic efforts in order to create and maintain a network of competent suppliers (Hahn et al., 1990; Degraeve and Roodhooft, 1999).

In this sense, the SRM might offer competitive advantages by monitoring market conditions, by establishing relationships with new suppliers and by improving the capabilities of existing ones.

However, even when there is a department in the company responsible for performing SRM, the process may be triggered by reasons other than strategic advantage (Silva, 2004). First, the purchasing department might receive several proposals from supplier competitors, offering the same materials or alternative materials or even replacing ones. Also, the purchasing department might decide to switch suppliers after considering costs or maintenance of manufacturing operations. In other cases, the switch may come from senior management, due to environmental factors, competitive pressures or technological change in the industry where the company operates (Krause, 1999). According to Silva (2004) SRM might also stem from the specific needs of a customer or governmental regulatory bodies, which set legal and fiscal parameters that require a change in the features of purchased material or changes in manufacturing conditions, marketing, transportation processes, among others. And finally, the most common situation is when the supplier presents chronic performance problems, either in quality, service delivery, time delivery or other indicators.

The challenge of remaining competitive in an increasingly global environment has led many firms to focus on improving their supply chains in order to deliver superior customer value and thereby create and maintain a strategic competitive advantage. Undeniably, effective supply chain management (SCM) has been associated with a variety of advantages including increased customer value (Handfield and Nichols, 1999), profitability (Claycomb et al., 1999) and reduced cycle times. According to Christensen et al., 2007, as organizations and supply chains reduce process and system variability they are able to maintain more effective operations at much lower inventory levels and with shorter lead-times.

Reducing delivery lead times is a way to diminish the average inventory levels. Financial benefits are also achieved by the organisation with project lead time reductions that focus on cost savings.

In this sense, specialized literature has acknowledged that the improvement of supply chain processes could be based on process-centric approaches (Trkman et al., 2007). The aim of the article is to reduce the lead time of the supplier relationship management process in a large manufacturing company in Brazil. In order to do so, it was improved the SRM process by following the business process management (BPM) approach.

This article is structured in five sections, including this introduction, and then presenting the theoretical framework, the research methodology used, results and conclusions.

Over many years, organizations have been focused mainly on products. They used to concentrate strength on scale production, manufacture a large number of standardized products was pretty important, and handled customers indiscriminately.

Dumas et al., (2013) defines Business Process Management (BPM) as the art and science of overseeing how work is performed in an organization to ensure consistent outcomes and seize improvement opportunities. In this context, the term “improvement” may take different meanings depending on the objectives of the organization. Typical examples of improvement objectives include reducing costs, execution times and error rates. Dumas emphasizes that BPM is not about improving the way individual activities are performed. Rather, it is about managing entire chains of events, activities and decisions that ultimately add value to the organization and its customers. These “chains of events, activities and decisions” are called processes.

According with Chen et al., (2004) customer responsiveness is a key building block in competitive advantage. Some researchers have argued that customer responsiveness transcends other measures of competitive advantage and that it permeates all the value-adding activities and functions of the supply-chain system. In a similar spirit, customer service, encompassing customer responsiveness, was recently found to have a direct positive relationship with financial performance.

Due to that, constant adjustments to an ever changing external world was mandatory.Thus, organizations had to adapt in order to answer to those quick changes. Nowadays organisations are increasingly interested in deeply understanding the role they play; so that they become skillful managing events more properly.

Concerned on that, skillful business processes management became an alternative capable of ensuring a good benchmarking, representing a set of methods and techniques assisting organizations in managing businesses based on knowledge and understanding their processes.

BPM´s main task, according to Muehlen (2005), is creating an alignment among the individual elements of the process: Inputs (information and resources), Outputs, Structure and Objectives. If the best alignment among these components is achieved, total performance of processes might be increased concerning quality, for example, fast suitability to environmental changes such as reduced cycle time, less waste, shorter downtime and dreased rework.

According to Weske (2012), Business Process Management or BPM; by means of proper documentation and wise automation of business processes within an organization provides cost, time and mistakes reduction while performing essential procedures. BPM also provides greater control on business operation, ability to adapt to unexpected situations, leading to these processes improvement, while turning it more profitable, in short, upgrading the whole organization.

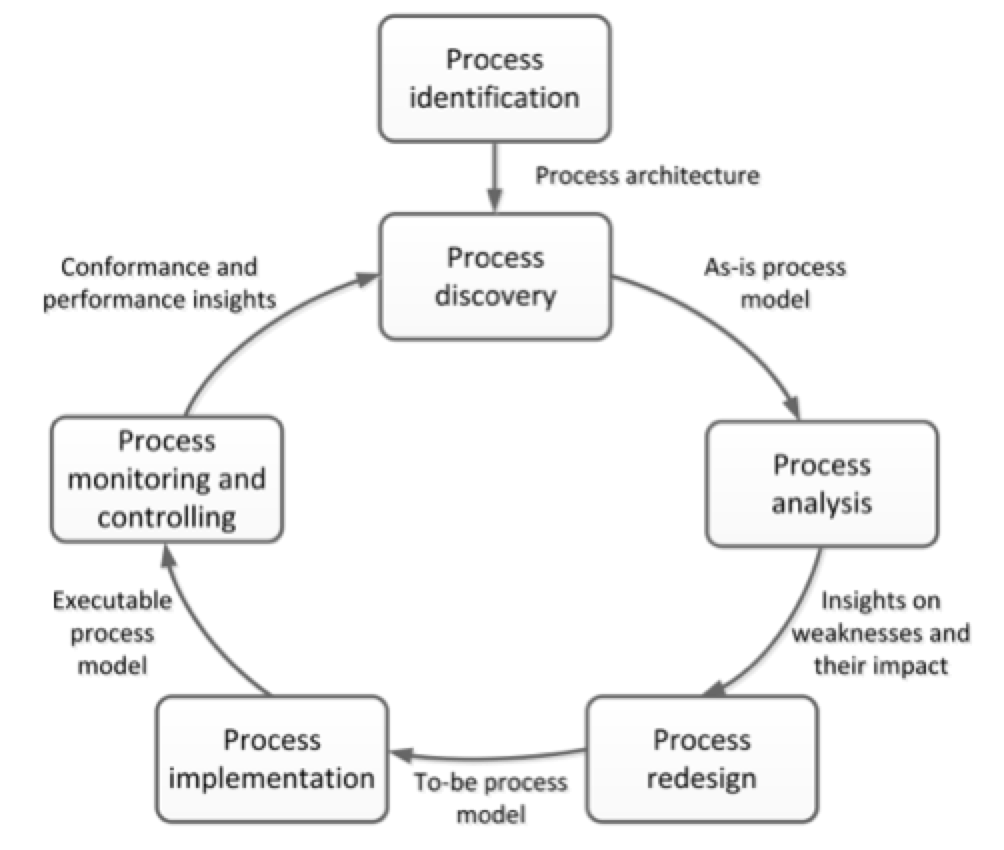

Business processes cycle defined by BPM according to Dumas et al., (2013), is illustrated in Figure 1, showing six major steps.

Figure 1 – BPM Lifecycle

Source: Dumas et al., (2013).

Process identification:In this phase, a business problem is exposed, processes relevant to the problem being addressed are identified, assessed, delimited and related to each other. The outcome of the process identification is a new or updated process architecture that provides an overall view of the processes in an organization and their relationships. In some cases, it is executed along with performance measurement identification, which can also be done with the process analysis phase.

Process discovery: At this step, process models named "As Is" are generated, representing the current situation. The main goal here is to understand what and how workflows are implemented within organization, i.e.; which activities are performed in the business process, deployment of these activities, people or departments involved and which business goals are reached by the process. These models are used as documentation of organization´s current processes and serve as next step basis of BPM´s life cycle.

Process analysis:In this phase, issues associated to the “As Is” process are identified, documented and whenever possible quantified using performance measures. The output of this phase is a structured collection of issues which are typically prioritized in terms of their impact, and sometimes also in terms of the estimated effort required to solve them.

Processes redesign: Also called process improvement, the goal of this phase is to identify changes to the process that would help addressing the issues identified in the previous phase and allow the organization to meet its performance objectives. To this end, multiple change options are analyzed and compared in terms of the chosen performance measures. This entails that process redesign and process analysis go hand-in-hand: As new change options are proposed, they are analyzed using process analysis techniques. Eventually, the most promising change options are combined, leading to a redesigned process. The output of this phase is typically a “To Be” process model, which serves as a basis for the next phase.

Process implementation: In this phase, the changes required to move from the “As Is” process to the “To Be” process are prepared and performed. Process implementation covers two aspects: organizational change management and process automation. Organizational change management refers to the set of activities required to change the way of working of all participants involved in the process. Process automation on the other hand, refers to the development and deployment of IT systems (or enhanced versions of existing IT systems) that support the “To Be” process.

Processes monitoring and controlling:Once the redesigned process is running, relevant data are collected and analyzed to determine how well the process is performing with respect to its performance measures and performance objectives. Bottlenecks, recurrent errors or deviations concerning the intended behavior are identified and, corrective actions are undertaken. New issues may then arise, in the same or in other processes, requiring the cycle to be repeated on a continuous basis.

According to Palmberg (2010), the reasons why an organization seeks BPM are particular to each organization. However, it is possible to identify the most common reasons according to Jeston and Nelis (2014), as shown below:

This article constitutes a descriptive exploratory study therefore sought to evaluate and suggest improvements in the process of suppliers / materials development from a Brazilian manufacturing industry, with the objective of reducing the high lead times of development processes.

Regarding the procedures used in the research, this can be considered a sources or search field research. When searching for sources include bibliographical and documental research. In field research the researcher observes the facts according to occur in reality, using techniques of interviews and direct observation.

The steps implemented after the literature review, during this study, were:

1) Process Identification;

2) Process Discovery (“As Is” Process Model);

3) Process Analysis (Cause identification);

4) Process Redesign (“To Be” Process Model).

To this end, it was used the Bizagi tool for process mapping “As Is” and “To Be”, lead times measurements, data analysis and causes analysis.

This case study was performed wihin a Brazilian industry inserted in the manufacturing segment. With revenues of nearly USD 200 million annually, the business holds the second position in domestic sales in its segment and is the largest exporter of its segment in Latin America, roughly 10% of company's sales is supplied to more than 35 countries. The company started its operations in the 50s and since then it operates on a family basis management. Its quality policy features mainly commitment with customer´s satisfaction. For such, continuous improvement is a main issue in the corporation, transferring technology and innovative designs to the whole market, always trying to exceed customers´ expectations and encouraging participative management and partnerships.

The object of this paper shall be applied in the Supplier Development Department, a sub-area of Procurement Department, in charge for ensure that the inputs purchase is always performed from reliable suppliers, providing cost savings to the organization. It´s important to observe that the company´s main goal is to maintain a range of supply chain partners able to offer competitive advantages in the medium and long run. In order to achieve that, it seeks strengthening existing supply base, ensuring development programs for the supply chain, production management, financial management and quality assurance areas. However, some suppliers may not always meet the needs of the case study company at the same speed rate the market requires, or not always willing and motivated to foster that partnership. These features are evaluated by Supplier Management, where delivery, quality and supply capability will be assessed indicating what measures can be individually taken.

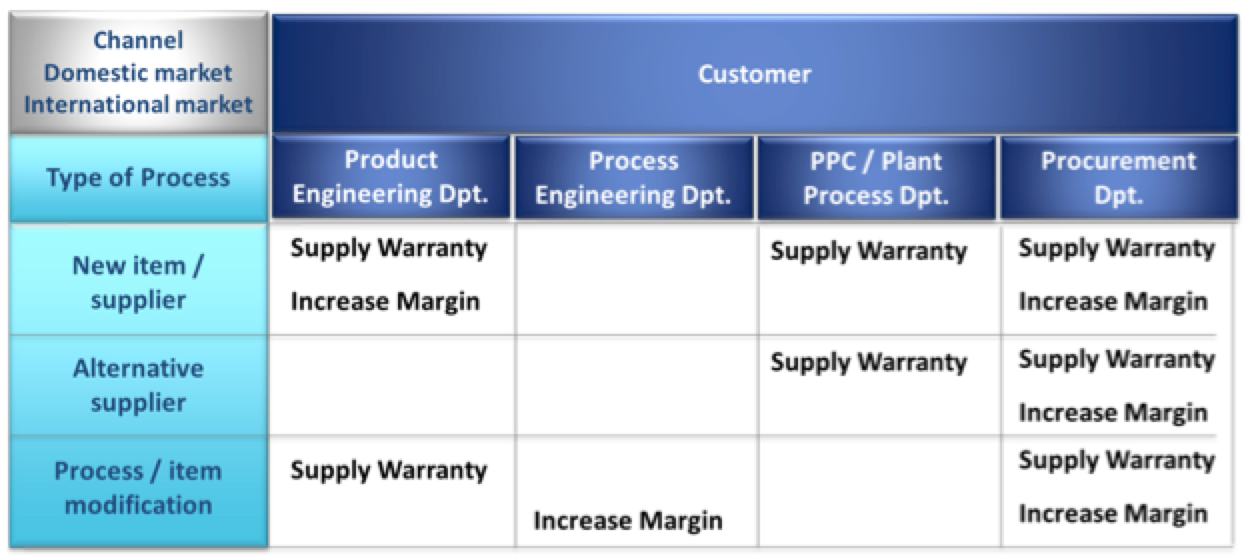

In order to define the process architecture, Dijkman approach was used regarding customers, kind of products, processes, and channels concerning Suppliers´ Development assessment.

The Suppliers´ Development department has as internal customers the following departments: Purchasing Department, Product Engineering Department, PPC (Production, Planning, and Control) Department and Plant Process. The supply warranty is regarded as products to these customers. The kinds of processes to supply these products are subdivided into new items or new suppliers, alternative vendors as well as changing existing processes or items. Both developments may happen considering both national and international markets, therefore here considered as channel types. In order to better understand how these aspects are interlinked, Figure 2 shows the products delivered to each customer and processes.

Figure 2 – Relationship Matrix for Process, Customer, Product.

Usually the Product Engineering Depatment requests the development of new purchasng items to be used in new products for future launching into the market, or changes in purchased items due to problems detected in the field, which can be solved with changes in materials or manufacturing processes. On the other hand, the Process Engineering Department requests items developments able to replace home manufactured items, seeking cost reductions, usually with changes in materials or manufacturing processes.

The PPC Department, following up increased consumption of purchased goods, points the necessity of developing alternative suppliers in order to meet new demands or in situations where present home manufacturing area is not able to supply the internal customers, so seeking for outsourcing Plant Process areas usually require developments when they have equipment breaking troubles identifying that purchased items can replace home manufacturing until the problems are solved.

The Procurement Department comprised by Purchasing and Supplier Development area, observe developments demands in various fields, wheter material changes opportunities or purchased items processes, aiming at reducing costs or improve supply assurance when even without financial gains, but suppliers point they will be changing sold items features. Alternative sources development are also considered by Development team in times of low quality and poor delivery rates by the current suppliers, as well as identifying opportunities for financial gains developing alternative suppliers. It is worth emphasizing that alternative suppliers are seen as companies belonging to the supply chain of the company; however they may not be approved for supplying certain items. Finally, new suppliers development happens in order to meet capacity, cost, quality requirements, innovation available in the market ,suppliers not belonging to company ´s suppliers roll.

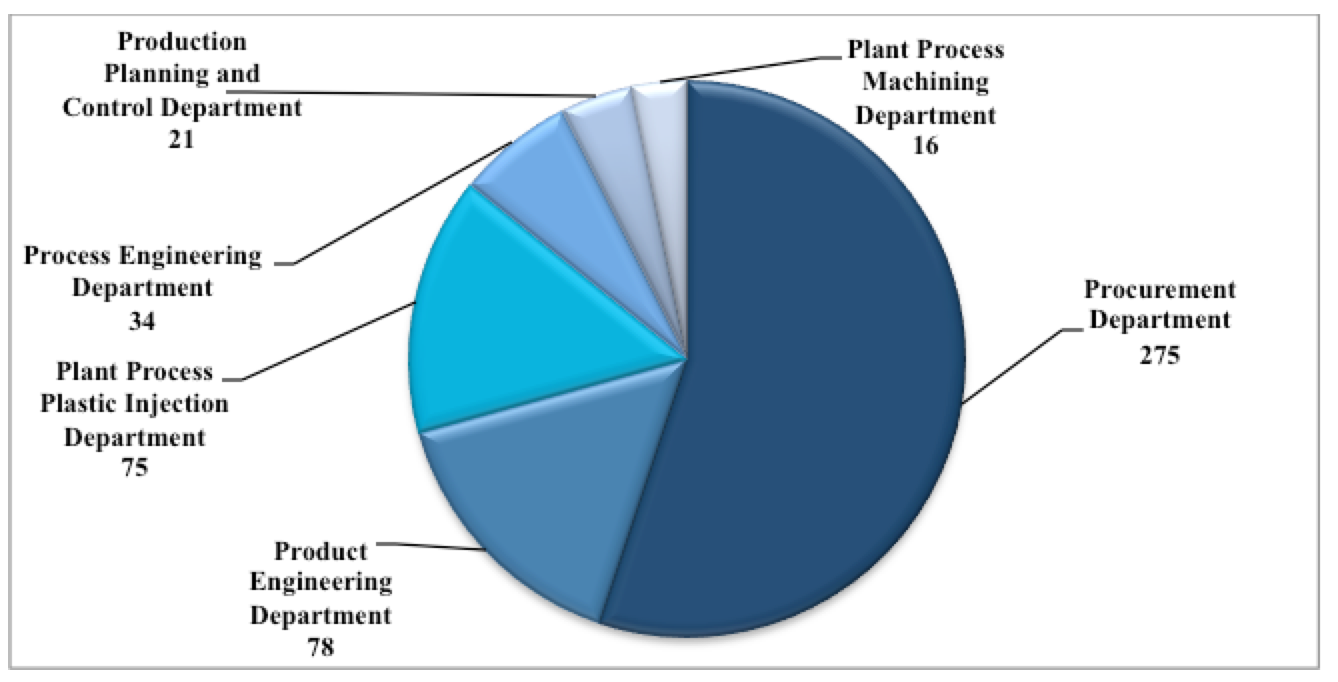

Currently, hightech developments requests are seen, however, due to a lack of methodology for criteria prioritization, long waiting times are observed besides long times of development cycle. Customers´different needs, make them compete among them because there isn´t an assured real capacity of the supplier development process. As shown in Figure 3, in the year of the case study, there are 499 requests and developments ongoing.

Figure 3 – Applications and Developments ongoing concerning Customer Area.

Considering that the central task in BPM, according to Muehlen (2005), is create an alignment linking processes individual elements, aiming at increasing the total performance of all processes, in a qualitative and quantitative basis, such as: shorter cycles, less waste, lower downtimes and elimination of rework. The organization tried to evaluate suppliers development process following the steps:

1) Process identification;

2) Mapping the current situation “As Is”;

3) Analysis and causes identification;

4) Redesign of the process with suggestions for improvements “To Be”.

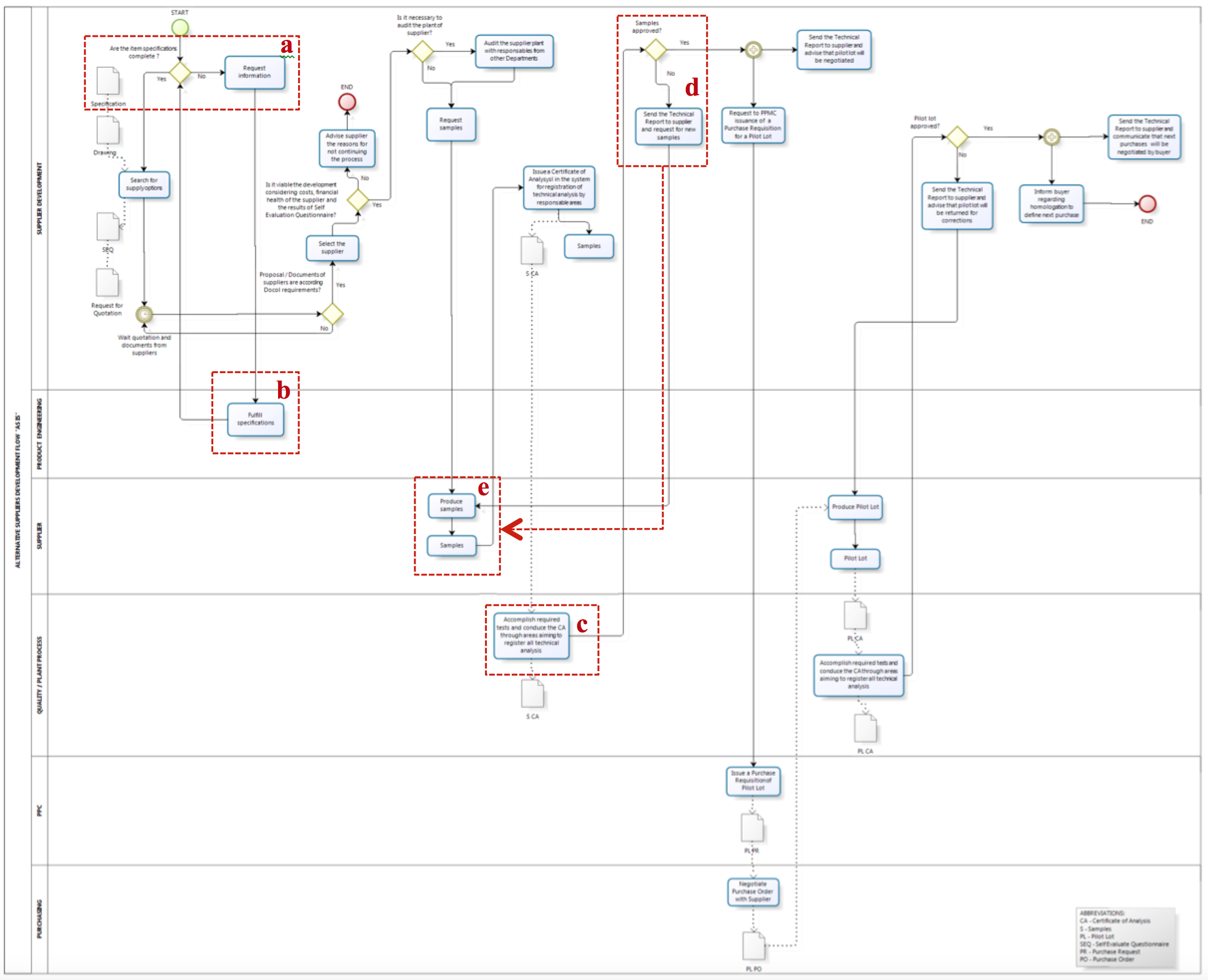

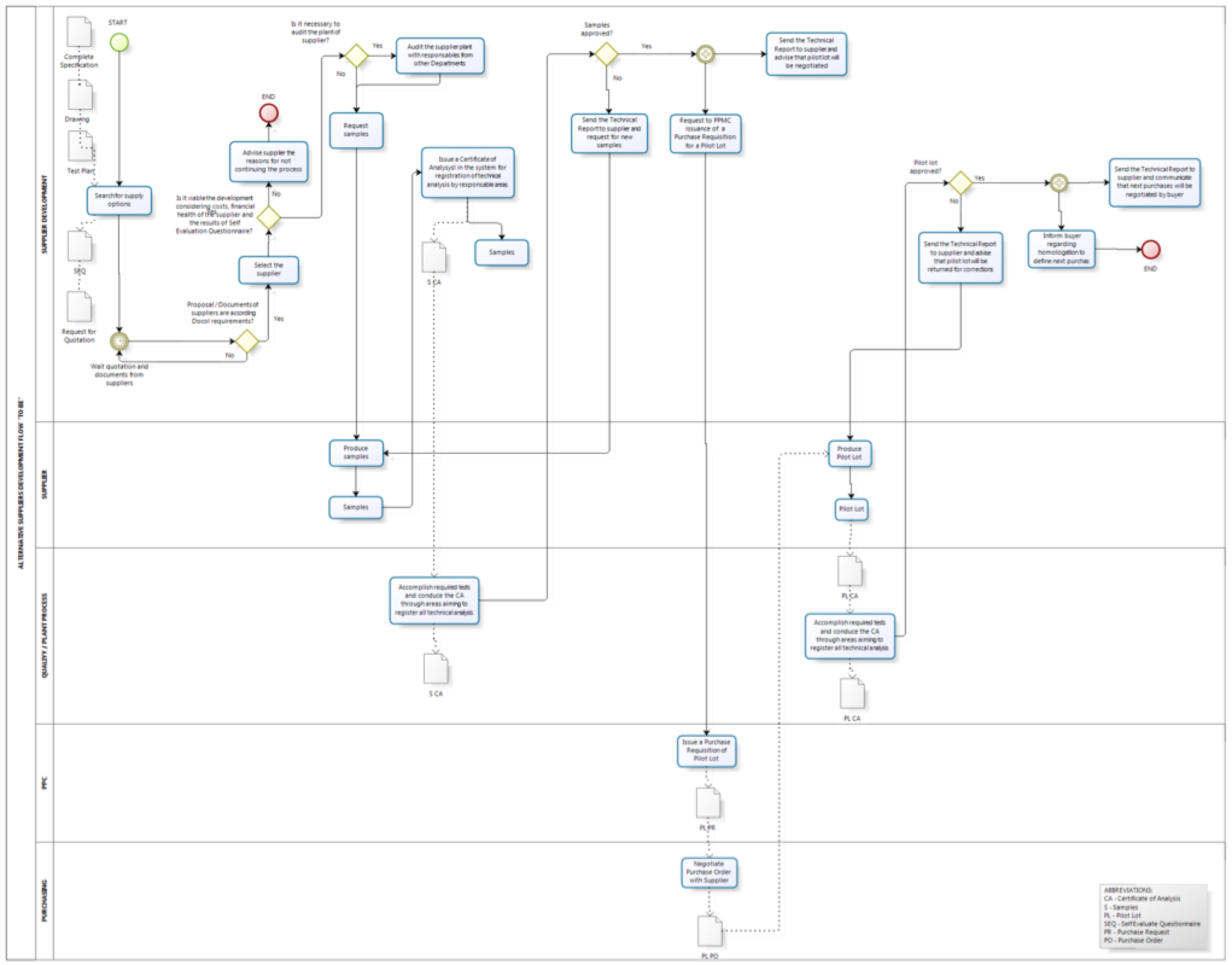

Considering different variables, which may directly impact on the various development kinds, as well as particularities of each process, it was tried to outline the present case study, mapping "As Is" of alternative suppliers’ process development, as shown in Figure 4.

For this study, it were considered for analysis, two families of materials, bronze raw material and packaging cardboard boxes, which have as reference the following current lead times for development:

• Raw material Bronze: Actual lead time - 6 months

• Cardboard Boxes Packaging: Actual lead time - 5 months

Figure 4 – Alternative Suppliers Development Flow "As Is"

After mapping the current situation, it was possible to identify the meaning cause of elevated lead time of developments, which interferes mainly in the activities highlighted in red on the Mapping “As Is”, which will be detailed as below:

It was possible to identify so, that the main reason for long developmet times, it was incomplete specifications and lack of descriptive of tests, which entailed in waits in various stages of the process, as well as rework for the supplier and departments of the company, both wastes that could be avoided.

These analyses supported the redesign of the process, so for the mapping “To Be”, highlight the importance of:

With the implementation of the suggestions presented in the “To Be” Model, it is estimated that the lead time for the development of bronze raw material and packaging cardboard boxes will occur as planned times, which means a significant reduction of 66% and 40%, respectively, compared with the current situation.

• Raw material Bronze: Plan lead time - 2 months – Reduction 66%

• Cardboard Boxes Packaging: Plan lead time - 3 months – Reduction 44%

The implementation of above proposals, with the monitoring processes will enable the optimization of processes, and so all the steps present in the BPM lifecycle, demonstrated by Weske (2012) may result in cyclical manner, enabling not only the lead time reduction of processes, but greater overall performance of the business, with less waste and lower costs.

Figure 5 –"To Be" Alternative Suppliers Development Flow.

The analysis of the real capacity of the Supplier Development Process as well as the development of prioritization criteria aligned with identified skills may be considered for future work.

This case study has shown that business processes management is an alternative capable of ensuring good results compared to competitiveness, featuring a set of methods and techniques table to assist the organization in managing its business based on knowledge and processes understanding. BPM is able to provide greater control for running the business, leading to processes improvement, as well as improving results and the whole organization.

The focus of this paper was achieved, demonstrating that using BPM concept in Supplier Development can reduce lead times of process and contribute to the primary objective of the area, which is operate efficiently and effectively, considering needs and strategic planning scope, promoting guaranteed delivery and increased margins for Organization.

The current situation mapping identified that incomplete specifications were the main reasons for long lead times to develop alternative suppliers. Incomplete specifications were also responsible for delays at process different stages, besides wasting time with reworks due to lack of consistent information.

The suggestion for developing a quotation checklist repecting materials family featuring necessary technical information including a complete test plan,using Bizagi workflow as a tool, will enable greater information reliability,general process monitoring using indicators to enable constant process optimization.

After the redesign of suppliers and materials development process, the lead time of the families of bronze raw material and packaging cardboard boxes, will be able to achieve an expressive reduction of 66% and 40% respectively. The total time for suppliers’ development of bronze raw material will be 2 months, and no more 6 months like before and the lead time for development of cardboard box packaging, will be 3 months and no more 5 months.

The monitoring of processes will enable the optimization of processes, and so all the steps present in the BPM lifecycle, demonstrated by Weske (2012) may result in cyclical manner, enabling not only the reduction of the lead time of the process, but a greater overall performance of the business, with less waste and lower costs.

In this scenario, it is possible to verify the adherence of the BPM methodology for the reduction of lead times, according to Trkman et. al. (2007) the effective use of IT and the role of business process management, are all vital in supply chain integration projects, since they enable changes in lead-times, process execution costs, quality of the process and inventory costs.

Chen, I. J., Paulraj, A., & Lado, A. A. (2004), “Strategic purchasing, supply management, and firm performance”, Journal of operations management, Vol. 22 No 5, pp. 505-523.

Christensen, W. J., Germain, R. N., & Birou, L. (2007), “Variance vs average: supply chain lead-time as a predictor of financial performance”, Supply Chain Management: An International Journal, Vol. 12 No 5, pp. 349-357.

Claycomb, C., Germain, R., & Dröge, C. (1999), “Total system JIT outcomes: inventory, organization and financial effects”, International Journal of Physical Distribution & Logistics Management, Vol. 29 No 10, pp. 612-630.

Degraeve, Z., & Roodhooft, F. (1999), “Effectively selecting suppliers using total cost of owenership”, Journal of Supply Chain Management, Vol 35 No 1, pp 5.

Dumas, M., La Rosa, M., Mendling, J., & Reijers, H. A. (2013), Fundamentals of business process management, Springer, Berlin.

Hahn, C. K., Watts, C. A., & Kim, K. Y. (1990), “The supplier development program: a conceptual model”, Journal of Purchasing and Materials Management, Vol. 26 No 2, pp. 2-7.

Handfield, R. B., & Nichols, E. L. (1999), Introduction to supply chain management, Prentice Hall, Upper Saddle River, NJ.

Jeston, J., & Nelis, J. (2014), Business process management, Routledge, New York, NY.

Lambert, D. M., & Schwieterman, M. A. (2012), “Supplier relationship management as a macro business process”, Supply Chain Management: An International Journal, Vol. 17 No 3, pp. 337-352.

Krause, D. R. (1999), “The antecedents of buying firms' efforts to improve suppliers”, Journal of operations management, Vol. 17 No 2, pp. 205-224.

Muehlen, M. Z. (2005), “Business Process Management and Innovation, SATM – Stevens Alliance for Technology Management, Vol. 9 No 3.

Palmberg, K. (2010), “Experiences of implementing process management: a multiple-case study”, Business Process Management Journal, Vol. 16 No 1, pp. 93-113.

Silva, J. E. D. (2004), “Um modelo de programa de desenvolvimento de fornecedores em redes de empresas” (“Supplier development program in business networks”), unpublished doctoral dissertation, Federal University of Santa Catarina, Florianopolis, SC.

Trkman, P., Indihar Stemberger, M., Jaklic, J., & Groznik, A. (2007), “Process approach to supply chain integration”, Supply Chain Management: An International Journal, Vol. 12 No 2, pp. 116-128.

Weske, M. (2012), Business process management: concepts, languages, architectures. Springer Science & Business Media, Berlim.

1. Degree Student in Industrial Engineering - Operations Management. UFSC - Universidade Federal de Santa Catarina (Federal University of Santa Catarina State). Email: isis_toledo@hotmail.com

2. Postgraduated in Audit and Business Management. UFSC - Universidade Federal de Santa Catarina (Federal University of Santa Catarina State). Email: andrevaldir@gmail.com

3. Doctor in Industrial Engineering. UFSC - Universidade Federal de Santa Catarina (Federal University of Santa Catarina State). Email: alvaro.lezana@ufsc.br

4. PhD in Engineering and Knowledge Management. UFSC - Universidade Federal de Santa Catarina (Federal University of Santa Catarina State). Email: m.uriona@ufsc.br

5. PhD in Engineering and Product Development. UFSC - Universidade Federal de Santa Catarina (Federal University of Santa Catarina State). Email: fernando.forcellini@ufsc.br