Vol. 38 (Nº 33) Año 2017. Pág. 32

Miroslava Gennadevna GLUKHOVA 1; , Nataliya Nikolaevna SHILOVA 2; Elena Petrovna KISELICA 3

Received: 20/05/2017 • Approved: 30/05/2017

ABSTRACT: Negative impact of industrial enterprises on the environment determines the need to search for and adopt the environmentally friendly technology of production. The best available technology (BAT) is aimed at improving the efficiency of environmental protection of the enterprises operation, with the economic feasibility of its use. Implementation of investment projects for the adoption of new technique and technology at various stages of the enterprise life cycle takes into consideration a variety of conditions and factors that influence the decision-making on the use of BAT. The article has justified the methodical approach of making managerial decisions on the adoption of the best available technology by enterprises in terms of the stages of the life cycle of their activity on the market, describing the conditions and factors of stimulating the adoption of BAT at the enterprise, as well as the environmental and economic efficiency of the projects under consideration in a highly competitive environment. Reasonable decision-making on the adoption of BAT in terms of a highly competitive target market will allow to ensure the effective development of the enterprise, and to improve the environmental safety of its activities. The suggested methodical approach provides an increase in motivation to adopt both economically profitable BAT and environmentally safe technology of production at industrial enterprises. |

RESUMEN: El impacto negativo de las empresas industriales sobre el medio ambiente determina la necesidad de buscar y adoptar la tecnología de producción ecológica. La mejor tecnología disponible (BAT) tiene como objetivo mejorar la eficiencia de la protección ambiental de la operación de las empresas, con la viabilidad económica de su uso. La implementación de proyectos de inversión para la adopción de nueva técnica y tecnología en diversas etapas del ciclo de vida empresarial toma en consideración una variedad de condiciones y factores que influyen en la toma de decisiones sobre el uso de las MTD. El artículo ha justificado el enfoque metódico de tomar decisiones empresariales sobre la adopción de la mejor tecnología disponible por las empresas en términos de las etapas del ciclo de vida de su actividad en el mercado, describiendo las condiciones y factores que estimulan la adopción de MTD en el mercado Así como la eficiencia medioambiental y económica de los proyectos considerados en un entorno altamente competitivo. Una toma de decisiones razonable sobre la adopción de MTD en términos de un mercado objetivo altamente competitivo permitirá garantizar el desarrollo efectivo de la empresa y mejorar la seguridad medioambiental de sus actividades. El enfoque metódico sugerido proporciona un aumento en la motivación para adoptar tanto las MTD económicamente rentables como la tecnología de producción ambientalmente segura en las empresas industriales. |

The issue of increasing the load on the ecosystem remains the most acute environmental problem with the highest social and economic importance. Environmental stress level affects all areas of human activity and life, but the problem of revising the principles of functioning and development of the industrial sector of the economy becomes particularly acute. The growth of industrial production of most enterprises is directly related to the growth of environmental pollution by industrial wastes, which constitute a danger both for the ecosystem and for the economic structures that produce such pollutants. Industrial enterprises whose production process focuses on extraction, processing and transportation of mineral resources increase the load of all kinds on the ecosystem in the process of production and marketing activities:

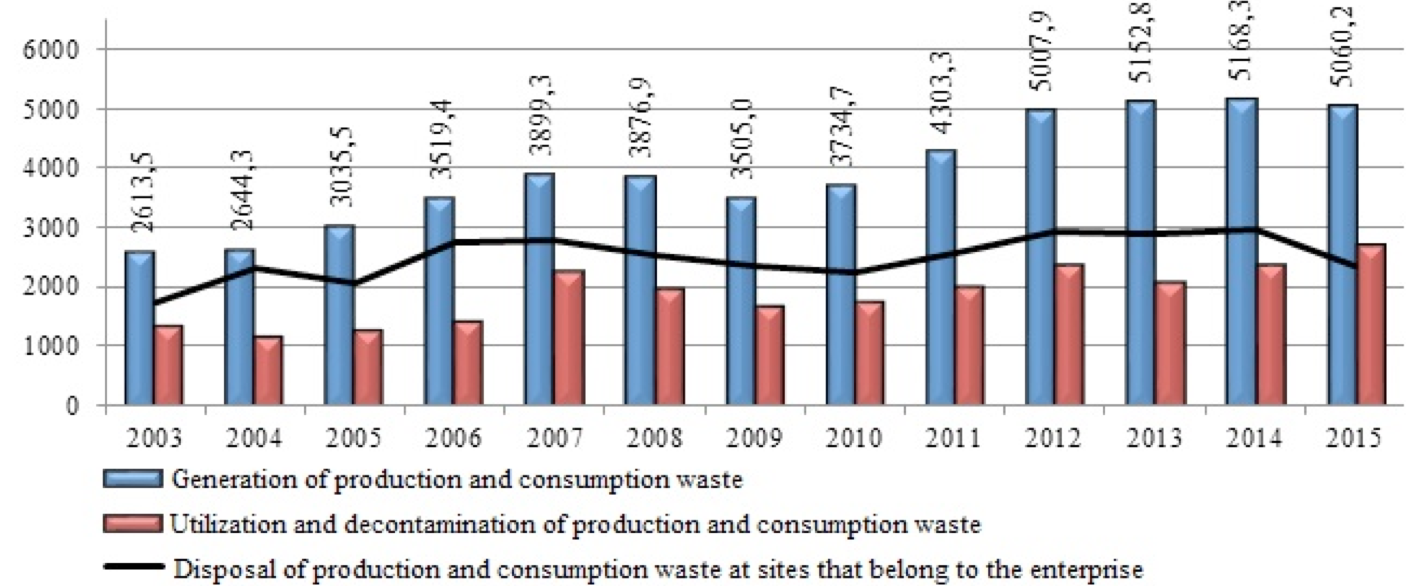

One can judge about the scale of the problem in the Russian Federation (further the RF) by the volume of generation of production and consumption waste, level of its utilization, neutralization and disposal of production and consumption waste at sites that belong to enterprises that produce waste (Figure 1).

Figure 1. Dynamics of the scale of generation, utilization, decontamination

and disposal of production and consumption waste at sites that belong

to enterprises, mln tons (compiled by the authors using sources:

Glukhova, and Petukhova, 2014; Koptyug 1992)

According to the Federal Service for Supervision of Natural Resource Usage, as of the beginning of 2014, RF has accumulated more than 35 bln tons of waste. The total volume of generation of hazardous waste (I-IV hazard class) per unit of GDP in current prices amounted to 1,741 (t/mln rub.).

The amount of production and consumption waste generated in 2015 is 5,060.2 mln tons, of which 2.18% is hazardous waste, 53.06% of production and consumption waste was utilized and decontaminated, about 7% was buried and 40% was stockpiled for storage in disposal areas, tailings of refinement and flotation, sludge accumulators and other sites of waste disposal. Almost all the hazardous waste generated in the country is of industrial origin.

The influence of the industrial sector of the RF on the level of environmental pollution ranges from 92.77% in 2005 to 97.54% in 2015. According to the Federal Service for Supervision of Natural Resource Usage, the share of mining operations in the structure of waste generation in the RF was 93%, the share of processing industries was 4.7% in 2014. The leading positions in the manufacturing industry in terms of the share in the volume of industrial waste of the RF are as follows:

|

‒ 22.94% |

|

‒ 17.95% |

|

‒ 15.95% |

|

‒ 8.80% |

|

‒ 7.98% |

|

‒ 5.76% |

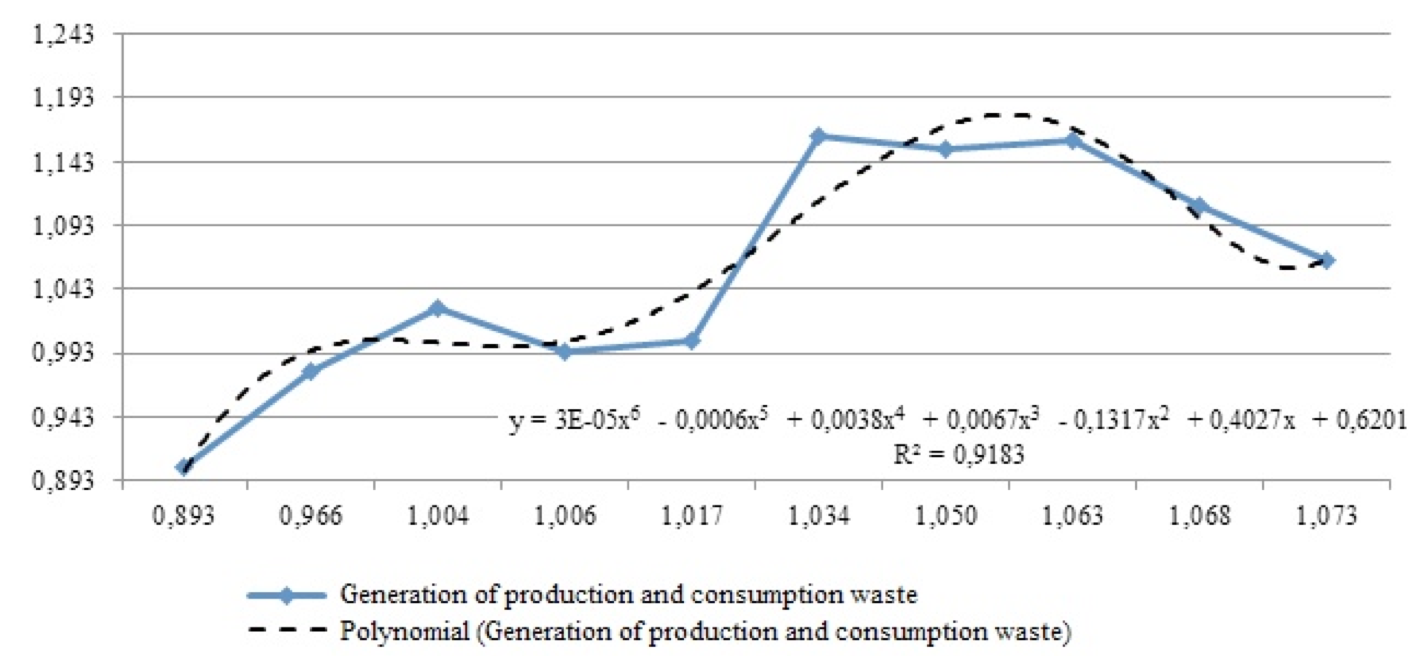

The impact of industrial production on the level of generation of production and consumption waste can be described by a mathematical dependence with 91.8% probability (Figure 2).

The main causes of environmental pollution are the use of outdated equipment, imperfect manufacturing technology, deterioration and critical condition of some production sites; liquidation and conservation of hazardous production facilities associated with the use of mineral resources are accompanied by a number of environmental problems.

Figure 2. The impact of industrial production growth rates on the

dynamics of the scale of generation of production and

consumption waste, chain index (compiled by the authors using

sources: Glukhova and Petukhova, 2014; Koptyug 1992)

The ingredient composition of industrial waste depends on the nature of business of industrial enterprises:

The burden on the ecosystem also increases due to the risks of industrial disasters, such as:

The largest environmental disasters have predetermined the development and adoption of environmental policy in the world and in the RF. Being in constant interaction with nature, the society increasingly feels the substantiated relevance of the creation of interrelations with the ecosystem that would ensure a stable environmental and economic compromise without violation of the natural balance and the evolutionary development of the planet; this relates to the current systems and new projects: progressive legal framework, modern concept of the technical diagnostics and timely repair of technical systems, use of the best available technology.

The authors deemed it necessary to study the detailed approach to the system of management and control of industrial processes of industrial enterprises based on the best available technology (hereinafter BAT) aimed at ensuring coordination of environmental and industrial policy, taking into consideration the modernization of production and improvement of technological processes. According to the Federal Law “On Environmental Protection” (Rebrik, Erokhina and Toschev, 2015), BAT is a technology of production of goods (products), performance of works and provision of services defined on the basis of contemporary achievements of science and technology and the best combination of criteria for achieving the targeted environmental protection, if there is a technical possibility of its application.

The legal framework on the use of the best available technology includes a set of laws and bylaws regulating the standards of the permissible environmental impact resulting from the adoption of BAT, sets the basic rules for regulating the introduction of BAT at enterprises through the total determination of the category of production facilities of all the enterprises located in the territory of the RF by the degree of negative impact on the environment, and obliges groups of enterprises that produce the most dangerous types of industrial production to adopt BAT on a mandatory basis, according to approved reference books (Lyugai, Pystina, Akopova, Popadko and Kosolapova, 2013).

Despite the intensive development of the legal framework and the creation of infrastructure of the regulatory authorities for the adoption of the BAT program in industrial enterprises, high penalties for environmental pollution are the key incentive for the BAT adoption (Kiselica and Golovkova, 2014). As such, enterprises face an alternative choice between using the advanced technology based on BAT and paying high penalties for pollution of the environment using old technology. In most cases, the BAT adoption becomes a priority, but an unconditional increase in the dynamics of the introduction of BAT at enterprises will be possible if it ensures real economic efficiency in the near future (Vesnina, Khristoforova and Kosorukova 2015; Ismailov and Ismailov, 2015).

There are following criteria inherent in BAT and innovative technology:

- use of low-waste technology;

- use of substances that are least dangerous for humans and the environment;

- consumption and nature of raw materials (including water) used in the process;

- possibility of regeneration and recycling of substances used in production (Andrutskiy 2009).

In this regard, the economic point of the BAT use is based on energy efficiency, resource husbandry and financial benefits of its use. At the same time, unlike the US and the EU, the adoption of BAT in the RF will be focused on energy efficiency in the first place (Decree of the Government of the Russian Federation dated December 24, 2014 N 2674-r). The energy strategy of Russia for the period until 2030 determines the place and role of energy conservation and energy efficiency of industrial enterprises on a long-term horizon, which has determined the priority of these indicators in assessing the efficiency of the BAT adoption (Shilova 2006; Economic and Environmental Benefits of Plants "MEGAPOLIS" of "ECOS", 2011; Energy Strategy of Russia Through to 2030, 2011). Resource husbandry is the second most important criterion used to assess the efficiency of the advanced technology. As practice has shown, this indicator allows making a choice between alternative options of the projects on adoption of the advanced technology in most cases. The technology able to ensure the best values of resource husbandry indicators will be recognized as the best (Glukhova, 2008). All the BATs included in the reference books in a mandatory manner contain estimates of energy efficiency and resource husbandry, according to legal standards and rules (Decree of the President of the Russian Federation dated June 4, 2008 No. 889). The real economic efficiency of the BAT use on a long-term horizon will be based on the financial capabilities of enterprises.

Meanwhile, the researchers identified a range of factors that should be taken into account when assessing future benefits and costs: boost in productivity, increase in the innovative potential of the enterprise, new markets development, improvement of confidence, stability, search for new sources of financing, etc. (Belozerskiy 2011, Oil and gas Extraction, N. D.). At the same time, this method is quite labor-intensive and contains miscalculations, since it requires a considerable amount of data, most of which should be provided in monetary terms, taking into consideration the long-term forecast of their use. Also of interest is the recommendation of the International organization OECD on the use of the methods of risk assessment and cost benefit analysis to find the economic efficiency and priority of adoption of environmental measures in the development and implementation of the public environmental expenditure programs (OECD Environmental Performance Reviews: Austria 2013). Despite the practice of using these methods, they have the above drawbacks. This can be confirmed by the calculations for similar environmental measures made several years later, where assessment brought different results.

The purpose of adoption of BAT at the enterprise is to increase the efficiency of environmental and economic production figures, which allow to ensure a stable economic growth and to improve the overall competitiveness in the industry. That said, the strategic objectives of the enterprise development on the market and the improvement of environmental policy in particular must be the key decision in the choice of the advanced technology and substantiation of the expediency of its adoption.

The authors suggest to form the concept of the system of managing the environmental policy and decision-making on the adoption of BAT based on the accounting of: the life cycle of the enterprise activity in the target market segment; purposes of the environmental management of the enterprise; possibility to achieve the production efficiency criteria in general. Each stage of the life cycle is described by the peculiarities of development of production and environmental management, as well as the availability of financial capabilities of the enterprise, which determines the prospects for the efficiency of the BAT adoption (Table 1).

Table 1. Characteristics of the BAT adoption system at various stages of the life cycle of the enterprise

Stages of the enterprise development |

Stage of the environmental policy |

Basic criteria for the BAT adoption |

Early stages: inception, formalization, accumulation of experience |

Response to the external environment and the possibility of the BAT adoption |

|

Active growth |

Understanding of the priority areas of environmental development and protection of the growth stability |

|

Maturity |

Information and ideological management of the environmental safety |

|

Recession, liquidation |

Liquidation of the accumulated environmental damage |

|

Each stage of the life cycle of the enterprise has its impact on both the development of production activities and the environmental policy of the enterprise and determines the priority of choosing a certain innovative technology. For example, it is advisable to consider the use of BAT that allows to create the best competitive advantages at the stage of the enterprise inception. This means that the enterprise will consider the boldest decisions in the field of BAT that feature an increased risk but expect the best result.

At the same time, the choice of the best technology will take into consideration the financial possibilities of the enterprise and the investment attractiveness of projects that ensure the significant reduction of the costs of environmental safety – a project that needs the least investment at high risks of projected revenues will be in priority when analyzing future costs and benefits. This approach will reflect not only in the priorities of the adoption of new technology, its analysis and evaluation, but also in the establishment of the environmental policy of the enterprise. In particular, the environmental monitoring at the stage of formation of production activities will provide the accumulation of experience and formalization of current tasks to ensure environmental safety. In turn, these tasks will be reflected in the plans for the strategic development of the enterprise in the industry.

A culture of environmental management is established at the stage of active development of the enterprise business, which is reflected in the integrated approach to the formation of the BAT adoption programs, the priority allocation of projects that ensure stable and reliable growth in the efficiency of production activities and environmental safety. High-risk projects will not be of interest, while technology that provides long-term financial benefits and improve competitiveness, on the contrary, will be in priority. At the same time, it is advisable to take measures aimed at developing the corporate culture of environmental management, promote the objectives of the environmental policy at the enterprise and tighten in-house requirements and sanctions for violators of environmental safety.

The enterprise strives to maintain competitive advantages and established traditions of environmental policy at the stage of maturity. A conservative approach to the BAT adoption programs is recommended in regard to the selection of the projects that will allow to ensure the industry average standards of the environmental safety. From the point of view of economic expediency, the projects aimed at reducing current costs, providing resource husbandry and increasing energy efficiency of production activities are more effective. In this regard, the system of preventive and defensive measures of environmental protection comes to the forefront, which reflects in the comprehensive planning of the production and environmental activities of the enterprise.

In case of liquidation of the production or operation of the enterprise, it is generally recommended to implement programs aimed at reducing the accumulated environmental damage – advanced technology of reclamation and rehabilitation of natural resources. As practice shows, such projects are implemented with the involvement of public services, which often fund and control execution of the programs. In turn, environmental standards for landscaping, water purification, fauna restoration, etc. will be the target indicators for such projects. Forecasting the environmental situation in the production liquidation areas doesn’t just allow to identify the actual damage, but also serves as a basis to amend the sectoral environmental norms and standards.

Selection and implementation of projects on improvement of the production technology that ensure an increase in the level of environmental safety at various stages of the life cycle of the enterprise are focused on a differentiated end result.

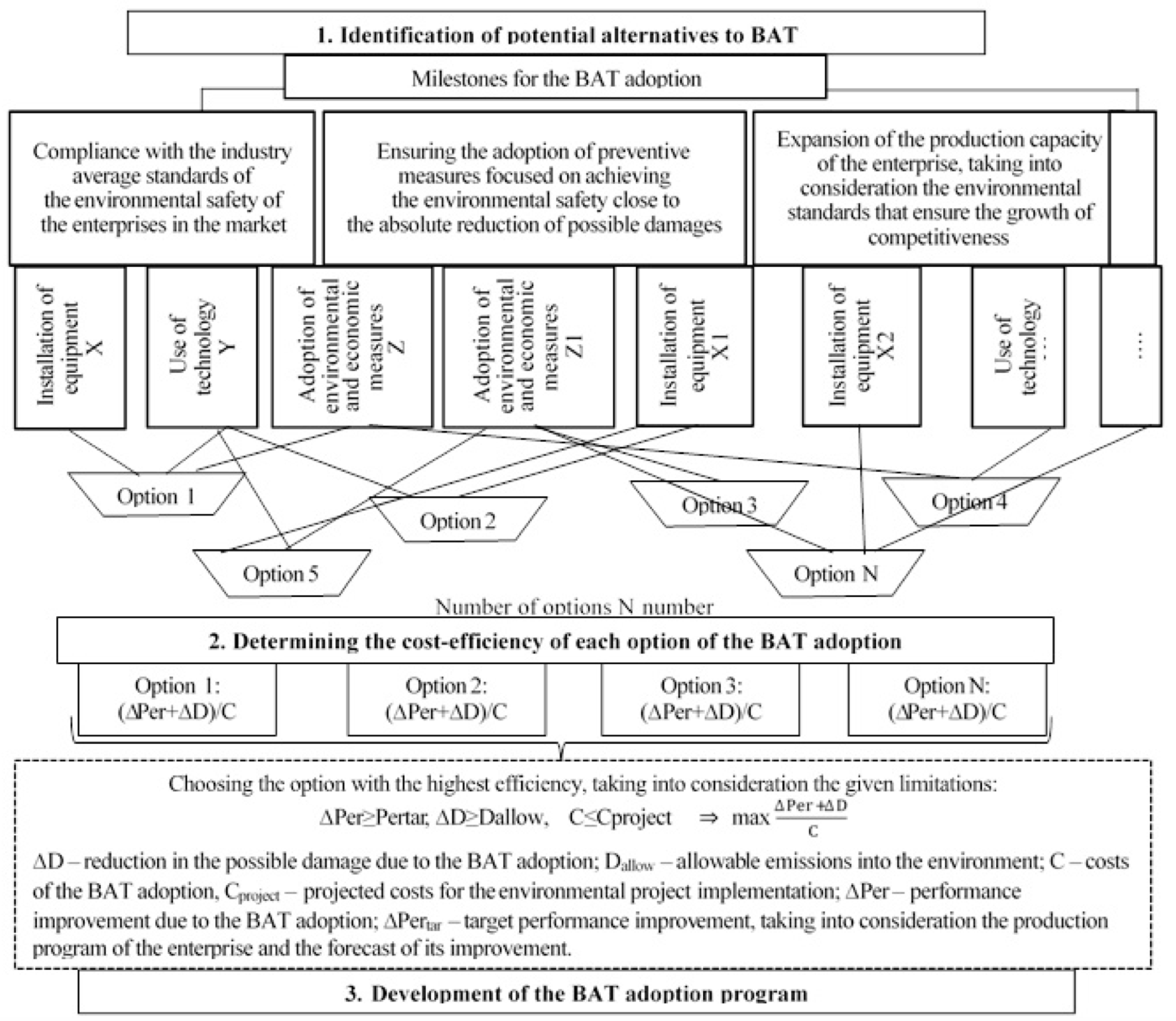

The authors suggest using the combinatorial optimization method in terms of the multi-variant implementation of measures to improve the environmental and economic activities of the enterprise – maximization of the possible increase in the enterprise productivity with minimization of the possible costs of the BAT adoption (Berezyukm, Rumyantseva, Merzlikina and Makarova, 2014). Limitations are accepted on maximizing and minimizing indicators, taking into consideration the planned volume of the output of products (works, services) and the standardized level of capital expenditures on the implementation of measures for the adoption of the best available technology. The recommended model of combinatorial optimization is adopted within the framework of the conceptual algorithm of the BAT establishment program and the assessment of the environmental and economic efficiency of the BAT projects (Figure 3).

Figure 3. Conceptual and logical model for drafting the BAT adoption program

based on the use of combinatorial optimization of the environmental

and economic efficiency of the projects

The suggested approach will allow to form a program of the BAT adoption, which ensures the expansion of production capacities at the expense of the adoption of new technology and the implementation of environmental projects aimed at reducing the possible damages, taking into consideration the limited costs of the program implementation.

Successful practices in applying the best available technology were noted at exporting enterprises in the first place. The oil and gas enterprises were the most vivid representatives of such practice. For example, the JSC Gazprom's greenhouse gas emission standard was revised using the reference book BREF “Oil and Gas Refineries” (Comments, Review of Amendments to 219-FZ, Gradual Transition of Enterprises to the Best Available Technology (BAT), N. D.). Positive practices were noted by pulp and paper organizations in the Arkhangelsk region which optimized the standards of discharging the biologically treated waste water. The application of the best available technology in the pulp and paper industry with deeper wood processing has provided an increase in both the environmental and economic efficiency of production activities (Begak and Guseva, N. D.).

Of particular interest is the practice of the BAT adoption at the enterprises of the metallurgical industry. For example, the project to improve the efficiency of air emissions purification in the production of aluminum was implemented on the basis of the approved environmental policy in 2011 in UC Rusal. Within the implementation of this project, new equipment for dry gas purification, complex gas removal system and automatic feed of raw materials was installed as the BAT adoption (Management of Production and Consumption Waste, N. D.). The new technology allows to reduce the greenhouse gas emissions several times, and to considerably reduce energy consumption and the cost of production.

The list of successful adoption of BAT in current enterprises in various industries is extensive. The peculiarities of the above examples include the use of the advanced technology in enterprises at the stage of maturity, which is noted in the specific nature of the applied environmental policy, system of the project investment and the results obtained.

Most enterprises already have a corporate environmental policy aimed at ensuring the environmental protection corresponding to the industry average standards of environmental safety. Projects are largely funded at the expense of own means or investment of holding structures. The implementation of projects for the BAT adoption results in a significant environmental effect and ensures a reduction in the need for resources. Moreover, the economic effect is ensured by reducing expenditures and production costs, rather than expanding production capacity and obtaining additional benefits.

At the stage of inception, establishment of new enterprises and production capacities, the BAT is adopted at the phase of the project development. The use of the advanced technology is aimed at both satisfying the demand in the market and obtaining perspective benefits, as well as preserving the environment in accordance with legally established standards. Such projects are normally funded through raised funds, lending from or investment by outside project participants. For example, of interest is the practice of establishment of a plant for the production of automotive glass – the Guardian project – Guardian Glass Rostov, launched in 2012 in Krasny Sulin in the Rostov region. Another project of establishment of a plant for the production of automotive sheet glass with the BAT use is LLC “Trakya Glass Rus” that was opened in 2013. The project was developed and implemented by well-known multinational corporations: the French Saint-Gobain and the Turkish Trakya Cam Sanayii (Federal Law dated January 10, 2002 No. 7-FZ). The project of production of Megapolis plants by Ecos also deserves special attention. The Megapolis plants ensure the technological processes of wastewater treatment, neutralization and disinfection of the exhaust air, i.e. installation of sewage treatment plants with zero waste emissions, and at the same time allow to achieve the reproduction of electricity and supply of treating agents located within the residential development. The practice of using this project is demonstrated for one of the countries of the Persian Gulf, supported by an investment company from Qatar (Chechkin 2014). The project is interesting due to its resulting efficiency of wastewater treatment, reproduction of electricity and the receipt of treating agents from recycled raw materials. The economic effect achieved from the use of this technology allows to apply it not just for residential buildings, which ensures a significant social effect, but also for industrial enterprises with the purpose of using treated sewage for technical water supply of industrial production.

In the context of reorganization of the market of industrial equipment and active production development at Russian machine-building enterprises, the BAT adoption constitutes one of the most important tasks in the production development. The plant of Kurgankhimmash LLC was a vivid example of the launch of the project of the use of the advanced technology in the production of industrial equipment. A batch of offshore tank containers to transport hydrochloric acid was first manufactured at the production facilities of this plant in 2016 by order of Gazprom Neft. The project is unique in its production technology, which has provided the company with not just the output of popular product and increase in revenue, but also with the reduction in greenhouse gas emissions and the amount of electricity consumed. The project was funded through the participation of partner enterprises and was controlled at the level of the Russian Ministry of Industry and Trade. The successful practice of the BAT adoption allowed Kurgankhimmash LLC to formalize a program of sustainable economic development that ensured the environmental safety of industrial production.

The BAT adoption at the stage of liquidation or conservation of production facilities is described in the RF national standard GOST R 55100-2012 only in emergency cases. This standard specifies the need to adopt preventive measures to stop environmental pollution. Environmental protection measures in the BAT framework, which are aimed at eliminating the actual environmental damage, are duly considered in standard regulations that refer only to the state property or to the territories of settlements. However, any type of extractive production faces the need for conservation of production facilities, sooner or later. The existing methods of assessing the actual environmental damage allow to make a conclusion about an almost irreparable threat to the environment from oil and gas enterprises, mining enterprises and other types of industries. Currently, the landscaping measures are adopted at the territories of closed production facilities, as well as cleaning from mechanical impurities, soil fertilizing, etc. However, none of these measures can recover more than 5% of the actual environmental damage. In this regard, the BAT development for the purposes of preemptive impact, as well as aimed at reclamation and environmental rehabilitation of the natural resources used is one of the most relevant tasks for the development of the environmental policy of the country. In our opinion, enterprises should take the costs of these measures into account as early as at the design stage. This approach will allow to assess both the economic and environmental efficiency of the implemented projects more reasonably.

A fragment of the BAT adoption program on the basis of the use of combinatorial optimization is presented in Table 2.

Table 2. Fragment of the BAT adoption Program at the coke-chemical production enterprise

# |

Contents of the measure |

Environmental impact (∆D≥Dallow) |

Performance impact, provided ∆Per≥Pertar |

Size of funding in current prices, provided C≤Cproject |

Executive in charge |

Adoption schedule (adoption priority) |

1 |

2 |

3 |

4 |

5 |

6 |

7 |

1. Inception stage (1979-1986) |

||||||

1. |

Development and approval of the Program of production control in the field of waste management |

840 thous. rub. |

40 thous. rub. |

15 thous. rub. |

Chief Technology Officer |

July 1979 |

2. |

Keeping a register of waste generation and movement |

167.5 thous. rub. |

64 thous. rub. |

75 thous. rub. |

Environmental Engineer |

Monthly |

3. |

Conclusion of an agreement with organizations for acceptance and transfer of industrial waste |

428 thous. rub. |

687 thous. rub. |

184 thous. rub. |

Environmental Engineer |

October 1979 |

4 |

Reconstruction of coke oven batteries |

380 thous. rub. |

495 mln rub. |

25.6 mln rub. |

Chief Technology Officer |

August 1985 |

5. |

…….. |

|

|

|

|

|

|

2. Active growth (2002-2007) |

|||||

1 |

Reconstruction of the benzol-scrubber department with a design capacity of 100 thous. m³ of gas per hour |

6.8 mln rub. |

926 mln rub. |

126 mln rub. |

Chief Technology Officer |

February 2003 |

2 |

Overhaul with partial relocation of oven walls and commissioning of coke oven batteries on “cold conservation”. |

40.4 mln rub. |

1.4 bln rub. |

38 mln rub. |

Chief Technology Officer |

April 2002 |

3 |

…. |

|

|

|

|

|

3. Maturity (2008 – present time) |

||||||

1 |

Installation of auto-dosers on coal silos with automatic system of controlling the process of the charge preparation |

60.2 mln rub. |

102 mln rub. |

6.8 mln rub. |

Chief Technology Officer |

March 2008 |

2 |

Reconstruction and commissioning of a coke oven battery with a design capacity of 440 thousand tons per year. |

64.8mln rub. |

480.2 mln rub. |

10.2 mln rub. |

Chief Technology Officer |

February 2010 |

3 |

Commissioning of a plant for purification of phenolic wastewater |

79.4 mln rub. |

1.2 mln rub. |

4.6 mln rub. |

Chief Technology Officer, Environmental Engineer |

October 2011 |

4 |

…. |

|

|

|

|

|

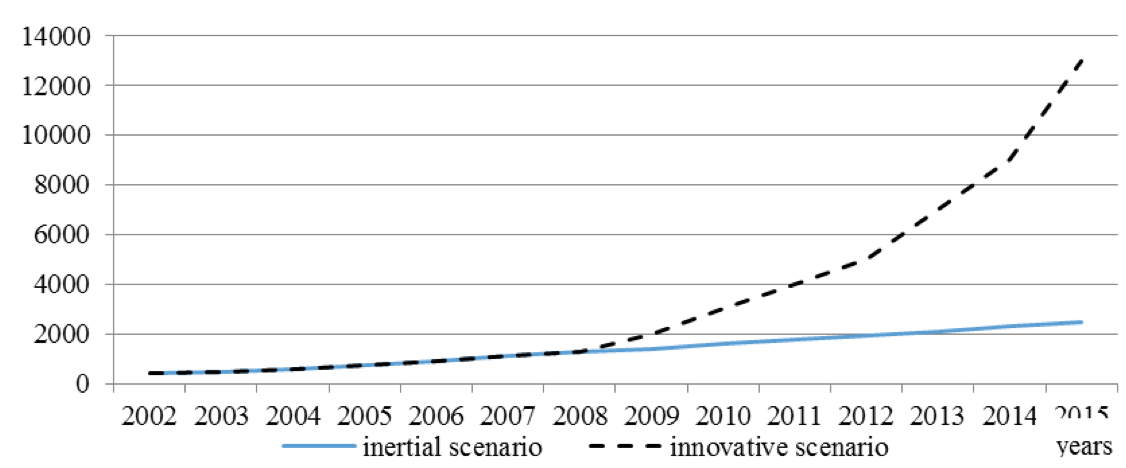

The combinatorial optimization method defines the priority of adoption of environmental protection measures, along with the introduction of new technology of expanding productivity in accordance with the principles of implementation of environmental policy in the framework of the life cycle stage, and is aimed at adoption of measures that result in the greatest impact both in terms of reducing possible damages and expanding the enterprise production capacity. The forecast of the dynamics of the prevented environmental damage due to the BAT adoption according to the “inertial” and “innovative” scenarios is shown in Figure 4.

Figure 4. Forecast of the dynamics of the prevented environmental damage

according to the "inertial" and "innovative" scenarios (due to the BAT adoption), mln. rub.

(compiled by the authors using sources: Kiselica and Golovkova, 2014; Chechkin 2014)

The forecast of the dynamics of the prevented environmental damage illustrates the feasibility of adoption of the best available technology that will allow enterprises to reduce the level of negative environmental impact, to increase the investment attractiveness of projects across the industry and the country, as well as to increase the competitiveness of the products.

The methodical approach to the economic substantiation of managerial decisions on the adoption of the best available technology by enterprises of the RF oil and gas sector in the context of the life cycle of their activities in the market, which was proposed by the authors, has been developed and tested in the framework of the initiative research project “Issues and prospects of development and modernization of the economy of Russia and the Tyumen region” (No. 01201254088 2012– 2015). The implementation of the author's approach ensures:

- establishment of the concept of the system of managing the industrial and environmental policy of the enterprise based on making managerial decisions on the adoption of the best available technology resulting from combinatorial optimization of the environmental and economic efficiency of the projects (of the life cycle of the enterprise activity in the target market segment;

- establishment of the goals of environmental management of the enterprise;

- creation of the possibility of achieving the production efficiency criteria.

The conceptual and logical model of establishment of the program of the BAT adoption based on the use of combinatorial optimization of the environmental and economic efficiency of projects is applicable to the use in any sectors of a production field. Its application is not limited by the harsh regulatory frameworks – the enterprise management can build its own combination of the system of the options to be assessed from the proposed range of targets for its technological development and basic criteria for the BAT adoption.

The authors see the following areas of further research: study of the industry specific nature of impact of technological factors of the macro environment, in-depth specification and the creation of the baseline criteria for the BAT adoption, adapted to industry specifics depending on the stage of the enterprise life cycle and the peculiarities of the development of the industry markets.

The concept of sustainable development in the modern world assumes achieving an optimal balance between the socio-economic development of mankind and preservation of the environment, along with the evolution of technological progress that ensures rationalization of the consumption of natural resources (Kiselica and Golovkova, 2016). The Russian environmental legislation switched to the principles of the best available technology only in 2008. However, thus far, most enterprises are considering the adoption of new technology only with the purpose to reduce penalties for environmental pollution. The practice of foreign companies in the BAT adoption is not always applicable for copying by domestic enterprises, taking into consideration legislative differences, distinctive features of the national economies, etc. The majority of Russian enterprises face the problem of insignificant funding of such projects and the availability of high risks in the adoption of innovative developments. It is almost impossible to ensure the proper result without the participation of state support in the implementation of major projects of national scale. The development of the regulatory and legal framework, infrastructure of the bodies regulating the BAT adoption at enterprises, the system of penalties and state support through the provision of the investment tax credit all increase the motivation to adopt the environmental safety programs through implementation of projects on adoption of the advanced production technology. However, small and medium-sized businesses still face high barriers in the adoption of innovative projects aimed at increasing the market development with a high level of competitiveness, which would meet the world standards of environmental safety of production. There are many projects and proposals to increase the development of the adoption of new technology in newly created enterprises, which attract the interest of the state, private enterprises, and society as a whole (Ricci, Eichhorst and Bongardt, 2008; On the State and Protection of the Environment in the Russian Federation in 2014).

Adoption of the best available technology is aimed at reducing the general level of environmental pollution and will ensure the accelerated technological production development. Environmental protection legislation on the BAT principle will allow to diversify the environmental standards for enterprises, given the specific of the natural conditions of the enterprise operation in various industries, use of various types of raw materials and energy resources, etc. The approved methodological provisions for assessment of the efficiency of the BAT adoption projects will increase the validity of their implementation in practice and ensure the investment attractiveness. An integrated approach to the development of the environmental protection on the basis of innovative production development will increase the interest of companies and multiply incentives for the adoption of the best available technology in various production industries.

The methodological approach to the selection of projects for the BAT adoption, which takes into consideration the stages of the enterprise life cycle, will ensure:

1. Increase in the productivity of the enterprise capital through:

2. Increase in the validity of decision-making on the BAT adoption through the identification of:

3. Strengthening of the investor confidence through:

4. Strengthening of evolution of programs to improve the level of environmental safety and conserve natural systems through demonstration of preventive attitude to environmental protection measures; implementation of the projects that take into consideration both the economic interests of individual economic entities and the environmental policy of the state and the world in general;

Improvement of the environmental situation in the RF and the competitiveness of Russian enterprises due to implementation of the modern methods of the system of managing the environmental protection will make a significant contribution to ensuring the sustainable development of the national economy in the world.

Andrutskiy, R., (2009). AD HOC analiz investitsiy na osnove CBA [AD HOC Investment Analysis on the Basis of CBA]. Accounting and Finance, 1. Date Views 05.03.2014 www.cfin.ru/finanalysis/invest/cost-benefit.shtml.

Applying Strategic Environmental Assessment: Good Practice Guidance For Development Cooperation, (2006). Date Views 16.08.2016 https://www.oecd.org/environment/environment-development/37353858.pdf

Belozerskiy, Yu.A., (2011). Adaptatsiya spravochnykh dokumentov po nailuchshim dostupnym tekhnologiyam k usloviyam vysokogo riska [Adaptation of Reference Documents on Best Available Technology to High-risk Conditions]. Advances in Chemistry and Chemical Technology, 25 (13): 57-62

Begak, M.V. and T.V. Guseva. (N. D.). Ekologicheskaya reforma v Rossii: ozhidaniya, problemy, illyuzii [Environmental Reform in Russia: Expectations, Problems, Illusions. National Information Agency "Natural Resources". Date Views 11.08.2016 www.burondt.ru/informacziya/publikaczii/publikacziya.html?PublishingType=1.

Berezyukm M.V., A.V. Rumyantseva, Yu.B. Merzlikina and D.N. Makarova, (2014). Vybor nailuchshikh dostupnykh tekhnologiy: ekonomicheskiye aspekty [Choosing the Best Available Technology: Economic Aspects]. Bulletin of UFU. Economics and Management Series, 2: 109-121.

Bina, O., A. Jurkeviciute and Z. Hui, (2009). Transition from Plan Environmental Impact Assessment to Strategic Environmental Assessment: Recommendations of the Project “Policy Instruments for a Chinese Sustainable Future”. Date Views 16.08.2016 www.sea-in-china.com/files/27_EN.pdf.

Chechkin, E.I., (2014). Rossiyskiy rynok stekla: “Vse prozrachno” [Russian Glass Market: "Everything is Transparent"]. Expert-Ural, 7: 588.

Dobycha nefti i gaza [Oil and gas Extraction]. (N. D.). Date Views 24.08.2016 oilloot.ru/component/content/article/85-promyshlennaya-bezopasnost-okhrana-truda-ekologiya-strakhovanie-opasnykh-obektov/354-vzaimovliyanie-sistem-truboprovodnogo-transporta-i-prirodnoj-sredy.

Decree of the Government of the Russian Federation dated December 24, 2014 N 2674-r "Ob utverzhdenii Perechnya oblastey primeneniya nailuchshikh dostupnykh tekhnologiy [About Approval of the List of Areas of Application of the Best Available Technology].

Decree of the President of the Russian Federation dated June 4, 2008 No. 889 "O nekotorykh merakh po povysheniyu energeticheskoy i ekologicheskoy effektivnosti rossiyskoy ekonomiki” [About Some Measures to Improve the Energy and Environmental Efficiency of the Russian Economy].

Ekonomicheskiye i ekologicheskiye preimushchestva Stantsiy “MEGAPOLIS” KOMPANII “EKOS” [Economic and Environmental Benefits of Plants "MEGAPOLIS" of "ECOS"], (2011). Industrial and Environmental Safety, 2 (52): 24-25.

Energy Strategy of Russia Through to 2030, approved by the Decree of the Government of the Russian Federation dated November 13, 2009 No. 1715-r.

Federal Law dated January 10, 2002 No. 7-FZ "Ob okhrane okruzhayushchey sredy” [On Environmental Protection].

Federal Law of the Russian Federation dated 23.11.2009 No. 261-FZ "Ob energosberezhenii i o povyshenii energeticheskoy effektivnosti i o vnesenii izmeneniy v otdelnyye zakonodatelnyye akty Rossiyskoy Federatsii” [On Energy Saving and Energy Efficiency Improvement and on Amendments to Certain Legislative Acts of the Russian Federation].

Glukhova, M.G., (2008). Ispolzovaniye kombinatornogo podkhoda pri formirovanii programmy rekonstruktsii gazotransportnoy sistemy predpriyatiya [Use of a Combinatorial Approach in the Formation of the Program of Reconstruction of the Gas Transportation System of the Enterprise]. In Fundamental and Applied Issues of the Efficient Development of the FEC and its Infrastructure. Tyumen: Tyumen Industrial University, pp. 128-136.

Glukhova, M.G. and M.S. Petukhova, (2014). Ekologo-ekonomicheskoye razvitiye sistemy normirovaniya vozdeystviya na okruzhayushchuyu sredu predpriyatiy neftegazovoy otrasli [Ecological and Economic Development of the System of Normalization of Adverse Impact of the Oil and Gas Industry Enterprises on the Environment]. Geology and Oil and Gas Content of the West Siberian Megabasin (Experience, Innovation). In the Proceedings of the Ninth International Scientific and Technical Conference, pp. 74-79.

GOST R 54097-2010 Group T58 The Russian Federation National Standard Resursosberezheniye. Nailuchshiye dostupnyye tekhnologii. Metodologiya identifikatsii. [Resource Husbandry. Best Available Technology. Methodology of Identification]. RCS 13.020 dated 01.01.2012.

Ismailov, R.A. and M.R. Ismailov, (2015). K voprosu ob ekologicheskoy modernizatsii predpriyatiy promyshlennosti [On the Question of Ecological Modernization of Industrial Enterprises]. Ecologist’s Reference Book, 1: 10-18.

Kiselica, E.P. and I.A. Golovkova, 2014. Organizatsiya i razrabotka innovatsionnykh ekologicheskikh proyektov s ispolzovaniyem tekhnoparkov [Organization and Development of Innovative Environmental Projects Using Technology Parks]. New University: Economics and Law Series, 4 (38): 4-8.

Kiselica, E.P. and I.A. Golovkova, (2016). Ekologicheskaya kompetentnost personala v obespechenii ekologicheskoy bezopasnosti proizvodstva neftegazodobyvayushchikh kompaniy. Problemy realizatsii upravlencheskoy kompetentnosti rukovoditelya organizatsii [Environmental Competence of Personnel in Ensuring the Environmental Safety of Production of Oil and Gas Companies. Issues of Realization of Administrative Competence of the Head of Organization]. Shadrinsk: ShSPU, pp. 248.

Kommentarii, obzor izmeneniy 219-FZ, poetapnyy perekhod predpriyatiy na nailuchshiye dostupnyye tekhnologii (NDT), kategorii obyektov, kriterii otneseniya, gos.uchet, PEK, prirodookhrannyye meropriyatiya [Comments, Review of Amendments to 219-FZ, Gradual Transition of Enterprises to the Best Available Technology (BAT), Categories of Objects, Classification Criteria, Government Accounting, IEC, Environmental Protection Measures]. Date Views 07.08.2016 ecostaff.ru/novosti/3029-219-fz-poetapnyj-perekhod-predpriyatij-na-nailuchshie-dostupnye-tekhnologii-ndt.

Koptyug, V.A., (1992). Konferentsiya OON po okruzhayushchey srede i razvitiyu [UN Conference on Environment and Development]. June 1992, Rio de Janeiro, pp. 20.

Lyugai, D.V., N.B. Pystina, G.S. Akopova, N.V. Popadko and E.V. Kosolapova, (2013). Nailuchshiye dostupnyye tekhnologii v neftegazovom komplekse [Best Available Technology in the Oil and Gas Complex]. Scientific and Technical Collection Bulletin of Gas Science, 2 (13): 9-13.

Obrashcheniye s otkhodami proizvodstva i potrebleniya [Management of Production and Consumption Waste]. (N. D.). Date Views 26.08.2016 gks.ru/free_doc/new_site/oxrana/tabl/oxr_otxod3.xls.

OECD Environmental Performance Reviews: Israel 2011, (2011). Date Views 16.08.2016 http://www.oecd.org/israel/oecd-environmental-performance-reviews-israel-2011-9789264117563-en.htm

OECD Environmental Performance Reviews: South Africa 2013, (2013). Date Views 16.08.2016 http://www.oecd.org/env/country-reviews/oecd-environmental-performance-reviews-south-africa-2013-9789264202887-en.htm

OECD Environmental Performance Reviews: Germany 2012, (2012). Date Views 16.08.2016 http://www.oecd.org/env/country-reviews/germany2012.htm

OECD Environmental Performance Reviews: Austria 2013, (2013). Date Views 16.08.2016 http://www.oecd.org/env/country-reviews/austria2013.htm

Recommendation of the Council on Good Practices for Public Environmental Expenditure Management. Date Views 23.08.2016 http://acts.oecd.org/Instruments/ShowInstrumentView.aspx?InstrumentID=175&InstrumentPID=171&Lang=en&Book

Rebrik, I.I., Yu.M. Erokhina and D.A. Toschev, (2015). Proizvodstvo alyuminiya v Rossii s tochki zreniya nailuchshikh dostupnykh tekhnologiy [Aluminium Smelting in Russia in Terms of the Best Available Technology]. BAT. Application in Various Industries, 2: 70-82.

Ricci, A., U. Eichhorst and D. Bongardt, (2008). Techniques for Impact and BAU Assessment in SEA. Date Views 25.08.2016 www.sea-in-china.com/ publications.html.

Shilova, N.N., (2006). Teoriya I Metodologiya Formirovaniya Sistemy Ratsionalnogo Ispolzovaniya Promyshlennykh Otkhodov Na Predpriyatiyakh Regionalnogo Stroitelnogo Kompleksa monografiya [Theory and Methodology of Formation of a System of Rational Use of Industrial Waste at enterprises of the Regional Construction Complex]. Tyumen: Tyumen State Architectonic Building University.

State Report “O sostoyanii i ob okhrane okruzhayushchey sredy Rossiyskoy Federatsii v 2014 godu [On the State and Protection of the Environment in the Russian Federation in 2014]. (N. D.). Date Views 10.08.2016 www.ecogosdoklad.ru/2014/wwwAir1_1.asp.

Strategic Environmental Assessment in Development Practice: A Review of Recent Experience, (2012). Date Views 21.08.2016 www.oecd-ilibrary. org/development.

Vesnina, E.N., G.I. Khristoforova and I.A. Kosorukova I.A., (2015). Normirovaniye negativnogo vozdeystviya na okruzhayushchuyu sredu na osnove nailuchshikh dostupnykh tekhnologiy v tsellyulozno-bumazhnoy promyshlennosti [Normalization of Adverse Effect on the Environment Based on the Best Available Technology in the Pulp and Paper Industry]. Application in Various Industries, 2: 101-118.

1. FSBE Institution of Higher Education “Industrial University of Tyumen”, P.O. Box 625000, Russia, Tyumen, Volodarsky's street No. 38. Email: mira_gluhova@mail.ru

2. FSBE Institution of Higher Education “Industrial University of Tyumen”, P.O. Box 625000, Russia, Tyumen, Volodarsky's street No. 38.

3. Tyumen State University, Russia, 625003, Tyumen, Volodarskogo Street, 6