HOME | ÍNDICE POR TÍTULO | NORMAS PUBLICACIÓN

HOME | ÍNDICE POR TÍTULO | NORMAS PUBLICACIÓN Espacios. Vol. 37 (Nº 23) Año 2016. Pág. 20

Wellington PEREIRA 1; Nilson de PAULA 2

Recibido: 12/04/16 • Aprobado: 30/04/2016

2. Types of biofuels and new technological routes

3. Biorefineries as a window of opportunity for Brazil

ABSTRACT: Ethanol production started mainly based on first generation ethanol, further technological innovation has made possible the use of farming and forestry residues as raw material for producing second generation ethanol. However, a big challenge lies ahead regarding production cost reduction and technological improvement. The main purpose of this article is to discuss the challenges and technological paths determining the evolution and prospects of ethanol, focusing on the assumption that natural resources can provide the foundation for technological leaps, also bringing about economic and environmental benefits. In this context, modern biorefineries using biomass have embodied windows of opportunities for the ethanol sector. |

RESUMO: A inovação tecnológica tornou possível utilizar resíduos agrícolas e florestais como matéria-prima para a produção de etanol de segunda geração. No entanto, existe um grande desafio em relação à redução de custos de produção e progresso tecnológico. Assim, o principal objetivo deste artigo é discutir os desafios e caminhos tecnológicos que determinam a evolução e as perspectivas do etanol, amparando-se no argumento de que os recursos naturais podem favorecer os saltos tecnológicos, também trazendo benefícios econômicos e ambientais. Neste contexto, as modernas biorrefinarias que utilizam a biomassa são janelas de oportunidades para o setor produtor de etanol. |

The evolution of the ethanol market allows us to understand that the presence of technology is not a specific condition for manufactured goods. Agricultural commodities can have in its production process a diverse range of applications and intensive use of knowledge and technology, including the basic development of raw materials until its final processing. Productive and technological relations prior to production are conditions for competitiveness in the upstream production of agricultural commodities. Such a discussion can be applied to the sugarcane ethanol case. The greater or lesser technological dynamics in a sector is not an isolated and static result from its past production model or from the use of a sort of raw materials. That is a result of the ability to overcome challenges through accumulation of knowledge and use of technologies to urge productivity jumps.

Ethanol is a key biofuel able to complement the whole demand for fuels, while it has the capacity to promote technological advancement and to generate more economic returns. Based on opportunities associated to the use of biomass for the production of second-generation biofuels, this can be a good window of opportunity for some countries like Brazil.

This paper aims to present the discussion about the use of natural resources and how the technological challenges that can generate positive externalities that can go beyond the production of ethanol. Thus, the use of biomass and its processing in biorefineries can be a window of opportunity. So, we argue Brazil can stand out in the use of sugarcane to make technological leaps and creating new market opportunities associated with the new use of biomass (organic or lignocellulosic materials).

Traditionally, ethanol production in Brazil has been associated with traditional methods for sugarcane processing. However, in the recent period it has been possible to incorporate new possibilities for the production of biofuels through new technological routes. Furthermore, ethanol can also be produced by converting cellulose (from organic raw materials) into sugar which is fermented to produce ethanol. The cellulose sources include biomass, such as agricultural waste, fast growth plants, forest residues and a big range of vegetal species (DOE, 2010). The technological frontier in biofuel production has evolved in a way that it is possible to use agricultural and forestry by-products for energy generation and for large scale biofuels production. However, the big challenge is how to reduce costs and how to enlarge the technological knowledge about the feasible use of lignocellulosic materials to produce second-generation or cellulosic biofuels in a sustainable and affordable way.

This sort of fuel is still in a relatively early stage about its production scale compared to the first generation ethanol, like the sugarcane ethanol in Brazil. Thus, the greater the efficiency and production of biofuels from biomass, the greater will be the potential for reducing costs of production compared to other current options. Therefore, investments in R&D performed by private companies and the public sector has become a key variable in this context (SIMS et al, 2008). This can be a great window of opportunity to be seized in order to stimulate the use of natural resources to advance in research, development and generation of new perspectives for biofuels and energy markets.

The lignocellulosic materials may become relatively less expensive as a source for ethanol production because they are abundant and they are not part of the human food chain (80% of the world's biomass comes from the forest). Thus, the factors that still limit the production of cellulosic ethanol are mainly of technological and economic nature (DOE, 2010). Despite the enormous availability of biomass, its use accounts for only 10% of global energy consumption, while the other 90% is distributed between non-renewable fossil fuels (80%), nuclear energy (6%), hydroelectricity (2%) and renewable solar energy. Biomass can be classified into two groups. The first one refers to the traditional use of biomass which is more primitive, like using firewood in stoves and polluting more. The second one refers to "modern" biomass, produced in a sustainable way and used to generate electricity and liquid fuels. It also includes forest, animal and agricultural residues, such as straw and bagasse from sugarcane (GOLDEMBERG, 2011; HIGAM and SINGH, 2011).

The biomass uses must be viewed in the context of the technological revolution involving new production techniques and the discovery of new energy sources (IDB, 2007). The conversion of cellulose into ethanol is an industrial process, but with biochemical feature, which requires extensive further development of scientific and technological knowledge. However, overcoming the challenges related to its economic viability has only been possible through State action. In this sense, the US has stood out for its investments in this activity and the federal government has given support for technological development for biofuels made from biomass. Thus, this issue has gained more importance in the political, environmental and economic agenda worldwide, particularly in Brazil, the second largest producer of ethanol and one of the countries with the highest potential in this market.

Biofuels can be classified in three groups according to the raw materials used and the technology applied in the production (IEA, 2010; HIGAM and SINGH, 2011):

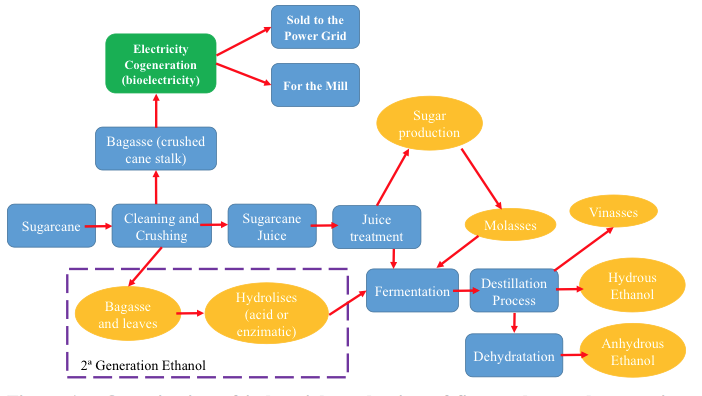

The second-generation biofuel production can be seen in the Figure 1. Although toward the production of first generation sugarcane ethanol, the scheme allows to understand all steps of first-generation ethanol production, as well as the complementary second-generation ethanol production linked to same industrial facility.

Figure 1 – Organization of industrial production of first and second-generation ethanol

Source: VALDES (2011, p. 08).

Figure 1 shows that the production of cellulosic ethanol from the byproducts of sugarcane (such as bagasse and straw) is associated with the production of first generation ethanol. Thus, the second-generation ethanol can be obtained both in industrial facilities which already have first-generation ethanol production, as well as for those which can produce autonomously (it will depend on the availability and the kind of biomass which will be used). In this case, Brazil has a favorable feature since the use of sugarcane byproducts reduce associated problems to the logistics of distribution of biomass, which is still a problem to be overcome for other sort of feedstock in other countries, like in the US.

Despite presenting the structure for sugarcane ethanol production, Figure 1 also illustrates the production of other second-generation biofuel as well. It turns out that second-generation biofuels production base is lignocellulosic biomass in its different options, thus it can be processed through different technological routes (HIGAM and SINGH, 2011; MELAMU, R and BLOTTNITZ, 2011). To increase the production of biofuel from the lignocellulosic biomass means it is necessary to know and understand about the cell wall structure in the plants. In some plants, whose structures are more flexible, cellulose and hemicellulose represent a major part of the cell wall, while in other cases the lignin is predominant, as it is the case of more rigid plants and wood. Thus, the cellulosic biomass has a set of more complex molecules than the existing liquid obtained in corn and sugarcane from traditional methods for first-generation ethanol production (FULLER, 2014; DASHTBAN, SCHRAFT and QIN, 2009).

Thus, it is necessary to breakdown the structures and molecules present in the cell wall to obtain cellulosic ethanol from biomass (such as bagasse and straw sugarcane). Most of the technologies associated with the production of cellulosic biofuels is still under development and recently began to be used on a commercial scale. But, the understanding of the technological processes to breakdown molecules started in Germany at the beginning of the twentieth century when some scientists applied some techniques to wood (BASTOS, 2007).

Alternative raw materials, such as biomass and inedible products are a way to overcome problems associated with first-generation biofuels, increasing the production in an environmentally and sustainable way, reducing the emission of greenhouse gases (LUQUE et al 2008; DASHTBAN, SCHRAFT and QIN, 2009). The production of ethanol from lignocellulose biomass requires further technological advances for dealing with genetic modifications of microorganisms that will digest the cellulose organic waste, what can become an affordable source for cellulosic ethanol production. In the case of sugarcane ethanol, its challenge lies in how to use the sugarcane byproducts (wasting biomass like straws and bagasse) with competitive costs in front of other currents competitors in the fuels market.

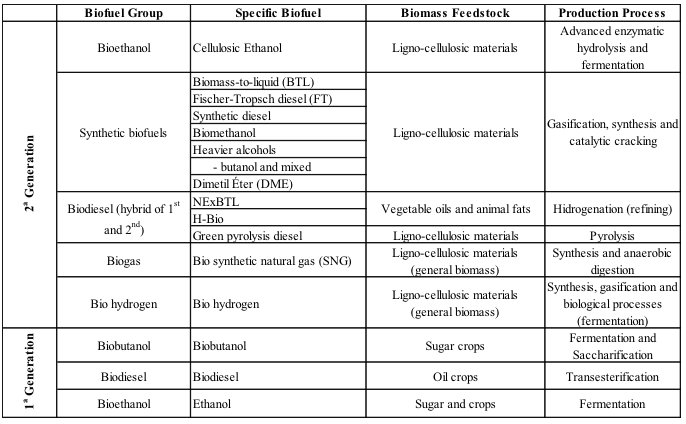

Second-generation biofuels are classified into different groups depending on the technology conversion route (chemical, biological or thermochemical) used for its production:

Table 1 allows identifies all biofuels of the first and second-generation that can be produced from the chemical, biological and thermochemical routes, which contributes to observe them based on the kind of raw materials and techniques used.

Table 1 – First and second-generation biofuels production from different raw materials and technologies

Source: from SIMS et al (2008, p. 43) and LUQUE et al (2008, p. 545).

Although doubts persist about one or another technology route, it is possible to establish their differences from its main features. The success of chemical and biological route also depends on the reduction of pre-treatment costs and on the improvement of the efficiency of enzymes (biologic route). The differential of thermochemical route has been the successful actions to reduce costs (SIMS et al, 2008). There are fewer obstacles for the thermochemical route because its technology has been available for longer and it has been more tested. The biomass gasification technology is already known and can already be used at lower costs, although advances are still necessary and the space for additional cost savings seems to be lower than in other cases (SIMS et al, 2008; LUQUE et al, 2008; BONOMI, 2010a).

The lignin obtained as a residue from the acid and/or enzymatic hydrolysis process can be used for power generation and heating boilers. In the thermochemical route (or biomass-to-liquid method - BTL) lignin is converted into gas together with cellulose and hemicellulose (SIMS et al, 2008; LUQUE et al, 2008). An important feature of thermochemical route is that it has the advantage of having a wide range of biomass options derived from agricultural and forest residues, byproducts of the food industry, etc. to be converted into biofuel. In addition, the thermochemical route makes possible to obtain fuels and chemicals products that can be used as substitutes for petroleum based products (DOE, 2010). But the main disadvantages of thermochemical conversion are the high costs to remove toxic substances from the gases. This has become a less efficient process due to the need for high temperatures to perform the conversion (DOE, 2010).

Thus, recent research on these technologies applied to the production of biofuels has shown that there is greater potential for cost reduction in the case of chemical and biological routes if compared to the thermochemical route where there is a smaller room for technological advances. Between the three routes, the biological route is still the most expensive and that which demands the largest technological developments, but also it is the option with wider margins for progress and cost reduction, which may make it more competitive and efficient.

A few years ago, when it started some important attempts at developing cellulosic ethanol in Brazil, the technological option adopted was different from that prevailing in the US. Rather than the biological route (with enzymatic hydrolysis) to produce cellulosic biofuel, the acid hydrolysis (chemical route) was preferred by companies in Brazil. Even though the chemical route gained more space in Brazil, there are already more attempts and studies to advance the production of cellulosic ethanol by the enzymatic pathway (SOUZA, 2013).

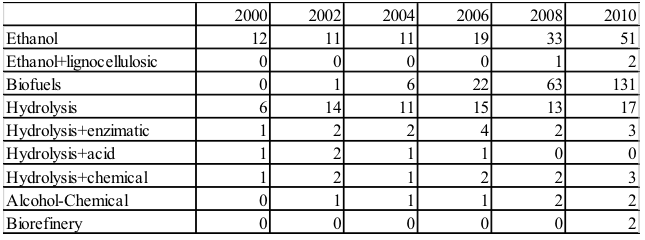

The research that has been conducted in Brazil on the second-generation ethanol are still highly concentrated in public universities, as shown Souza (2013). The author surveyed all research groups in the CNPq data platform and he was able to demonstrate the evolution of research groups related to areas whose keywords are linked to the second-generation ethanol. One of the filters used by Souza (2013) was trying to see if there were some terms related to ethanol in the name of research groups, in the name of research areas and/or in the keywords of these research areas. Table 2 presents the results and shows that after 2000 the attention to issues related to cellulosic ethanol increased in the country. Thus, the Table 2 allows you to check the number of groups that have straight relation with the selected keywords. Additional data presented by Souza (2013) showed that when the filter is applied to the same words in the bibliographical references and or in the titles of papers, the amount of related groups had a bigger growth.

Table 2 – Number of research groups related to keywords selected, 2000-2010

Fonte: SOUZA (2013, p. 98).

Dedini S/A was one of the first companies in Brazil to research and to order research associated the cellulosic ethanol. This company produces machines and equipments for sugarcane facilities, and it has interests in provide technical support for the production of cellulosic ethanol in large scale. The project called Dedini Rapid Hydrolysis (DHR) was a pioneer in this sense (BASTOS, 2007). Dedini was also a pioneer in establishing a great partnership with FAPESP (The São Paulo Research Foundation). These attempts began in 1987 with ethanol conversion tests on inputs using a process called Organosolv and other with sulfuric acid diluted in the hydrolysis (BON and FERRARA, 2007; RODRIGUES, 2006). The Organolov was the dissolution of lignin in some solvent to break all the cellulose structure, with the chemical hydrolysis of hemicellulose and cellulose. The process could be mixed with acidic or enzymatic hydrolysis. But the DHR method chose the acid route because it was already better known and a tested technology (CGEE, 2009). The DHR method has been patented in the United States, Russia and European Union (VARRICHIO, 2011).

The chemical route, with the use of acids requires a better control to avoid undesired reactions, but it is known and relatively less expensive than the enzymatic hydrolysis technology. However, the use of acids requires advances in the treatment of potential corrosion that may damage vehicle engines, for example (BASTOS, 2007; RODRIGUES, 2006).

Brazil has a great benefit and it should be used as an advantage in the race to increase the production of ethanol from hydrolysis (either acid or enzymatic). Brazil has a high volume of raw material derived from sugarcane bagasse, which is already ready for hydrolysis because all that lignocellulosic biomass was previously milled, and this process reduces the size of the molecules in advance. Thus, Brazilian sugarcane mills have competitive advantages in terms of cost and logistics for storage, transportation and distribution compared to the countries that do not use sugarcane.

The sugarcane bagasse is composed by 46% of cellulose, 25% of hemicellulose, 21% of lignin and 8% of other components (GOLDEMBERG, 2011). Together the cellulose and hemicellulose account for 71% of the sugarcane biomass, which is a rich source for cellulosic ethanol production.

The Brazilian insertion in the future shape of ethanol market, including cellulosic ethanol from biomass and all the advanced technologies which will be demanded, should be considered in the design of competitive strategies for the sector by policy. Moreover, it means not only to find ways to increase the production of more environmentally sustainable biofuels, but also to enable the use of the window of opportunities associated to the second-generation ethanol. This can contribute to the economic dynamics and to the scientific and technological progress in a sector where Brazil has a historical advantage.

Projections indicated that the first facilities to produce cellulosic ethanol would effectively be ready only in 2012. However, the first large facilities began to get ready only in 2014, both in Brazil and in the US. Even so, there are still doubts whether the production of this biofuel will have the capacity to meet global demand for biofuels in 2030 (SIMS et al, 2008; EGGERT, Greåker and PORTTER, 2011). The number of companies which are already developing some sort of cellulosic ethanol production in Brazil is still small, but there are important initiatives. Some companies can be mentioned: Agroindustrial Odebrecht (former ETH Bioenergia), São Manoel Mill (linked to Coopersucar) in partnership with the Technology Center for Sugarcane - CTC, Raizen (joint-venture between Shell and Cosan), GranBio (managed by GranInvestimentos S/A, in Alagoas) and Petrobras, which has been working on developing its own technology (SOUZA, 2013).

However, despite the high expectation for researches related to enzymatic hydrolysis in Brazil, Souza (2013, p. 159) concludes that the country "is not generating enough efforts in research related to these issues". It is known the enzymatic conversion is considered the most promising in terms of technological leaps and productivity. Thus, it is important to pay attention to this result because the technological evolution is running fast and Brazil can appear in a disadvantaged position if compared to other international producers such as the US, where research on enzymatic conversion has been encouraged through public policies.

The barriers to the expansion of the second-generation biofuels production should not be neglected. As pointed earlier, in addition to economic and technological constraints there are logistical challenges in transportation and storage of raw materials (lignocellulosic biomass). This is a minor problem for the Brazilian sugarcane, but not for other sort of raw materials, particularly in US. To overcome these problems will be necessary more participation by the fuel industry and more acceptance by the consumers. For these reasons, the government should develop actions for this segment in order to accelerate this process and to unveil a promising scenario, minimizing the uncertainties that have inhibited investment in biofuel production and thereby contributing to economic, technological and environmental development.

The technological challenges should not be seen as insurmountable barriers or even not stimulate new projects for the expansion of biofuels production. The ethanol market can generate opportunities, which may encourage more production and more consumption of cleaner and environmentally sustainable biofuels. Thus, this will tend to help boosting innovation efforts that will contribute to generate more economic benefits.

Technological development of new genetic varieties of sugarcane and the second-generation ethanol will create a positive impact over the entire sugar and ethanol industry in the next years. An essential part of that context is the modern biorefineries that use biomass as an input. We can be observing an important window of opportunity for this industry and to other economic activities related. Besides the positive potential and other good features that distinguish sugarcane ethanol compared to more polluting fossil fuels, there is a possibility of integrated production for first and second-generation ethanol. Moreover, other products can be obtained from the same basic raw material what can be an opportunity. The opportunities are associated with the new products and biofuels obtained from the industrial processing of biomass in biorefineries. Thus, the ethanol producer segment could be reshaped in a way to expand and diversify the list of products obtained from the expansion of the bioindustry. A strategic variable in the sustainability of this industry is the organization of raw materials/biomass supply (BOMTEMPO and CHAVES, 2014). So far, Brazil has advantages in logistics and in regular sugarcane biomass supply. However, these possibilities are conditioned to struggles for more innovation in the bioproducts industry (bioeconomy), whose structure is still gaining more specific definitions (BOMTEMPO e CHAVES, 2014).

Regarding the sugar and ethanol industry, the possibilities associated with bioproducts and second-generation biofuels are wide, particularly because they require more technological efforts, including the costs reduction with the sugarcane, which represents 60-68% of the overall costs for the current ethanol production (Rosillo-CALLE, 2010). Thus, as stated Cortez (2010), the 'Brazilian model' characterized by the production of sugar and ethanol should change and incorporate a new ethanol production paradigm where there is a complete use of the sugarcane. That can promote the expansion of the capabilities and competitiveness in the different economic areas related to sugarcane from a more competitive use of biomass.

However, the exploitation of this potential must be seen from the perspective of an ongoing process that is still shaping a new industry. That is, besides increasing the production of ethanol and other biofuels, the biorefinery may also provides raw materials and inputs for other products/industries, such as chemical from biomass (BOMTEMPO and CHAVES, 2014). Additionally, the products obtained from biomass can contribute to the reduction of emission of pollutants throughout its life cycle. In this context, "the biorefinery concept is based on those similar to technologies used in the petrochemical refinery, [... but] offering greater potential because of the huge variety of renewable biomass" (Franco and GARZÓN, 2010, p. 761). Biorefineries can use biomass from animal or vegetal origin, like organic wastes such as bagasse from sugarcane (SOUZA AGUIAR and SILVA, 2010). The use of biomass has been occurring for a long time, but the biomass processing with more advanced techniques for electricity generation and biofuels on a large scale, for instance, is relatively recent (BOMTEMPO, 2010).

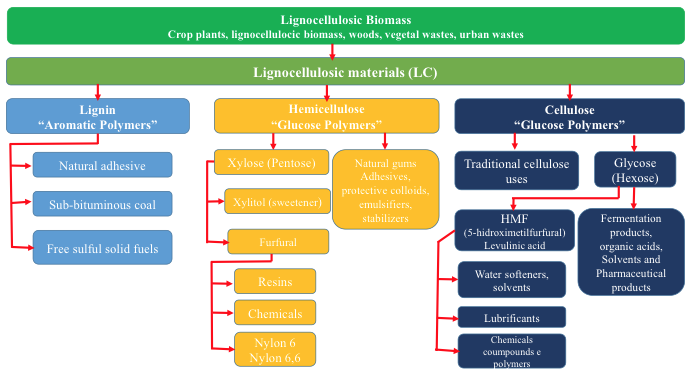

To achieve competitiveness and to use all the lignocellulosic biomass, biorefineries must be able to process all three components of biomass, which are lignin, hemicellulose and cellulose (PEREIRA JUNIOR, 2010; BOMTEMPO, 2010). Each of these three parts of the biomass can produce different products, as shown in Figure 2. It shows that there is a wide range of products which can be obtained, enhancing and adding more competitiveness and economic return to the industrial process from the biomass in biorefineries, what can go much beyond the ethanol.

Figure 2 – Products that can be obtained from the processing of lignocellulosic biomass

Source: Franco and Garzón (2010, p. 764).

Specifically regarding to ethanol, efforts to increase production and economic/environmental returns are directly related to the expansion of biorefineries, which has become essential in the ethanol productive and innovative system. As stated by Bomtempo (2010), the integrated biorefinery (first and second-generation ethanol production in an integrated industrial facility) has not became part of sugar-ethanol industry in a large-scale so far. That is because only recently the first plants to produce second-generation ethanol began operating in Brazil and the US. Thus, the concept of integrated biorefineries, in which treatment and conversion occur together, still need to be tested and accepted in the current sugar-ethanol industry (BOMTEMPO, 2010; BOMTEMPO and Chagas, 2014).

In this context, innovation is an important element related to the success in this kind of integration process that has to work to increase the efficiency in the biorefineries. Thus, the potential opportunities associated with biofuel production and new product from biomass should be a strategic variable in the design and implementation of public policy. Only in this way the country can benefit itself from current and future advantages in this new industry.

Ethanol is a product based on natural resources in which Brazil has competitiveness and it can work as a local catalyst for new markets opportunities. From the opportunities indicated before, there are many scientific and technological challenges that can generate spillovers to other activities which be benefited from the advances derived from the second-generation ethanol production. The history and the extension of the ethanol market, with strong federal government participation, is an important characteristic and that can not be ignored to get success in the future.

Even though ethanol is a product based on natural resource it does not mean that characteristic limits the ways to achieve new capabilities and new technological pathways whose can stimulate more local skills and more knowledge accumulation in and from the sugar-ethanol industry dynamics. If this result is really considered strategic by the federal government, it is important that public policies acts to overcome the competitive challenges related to biomass and take this as an opportunity to seize a new era in the ethanol productive and innovative system.

The opportunities associated with the increase in ethanol production from lignocellulosic materials are subject to risks and uncertainties. But they can be shortened by the State action in a way it can encourage agents in the market to face all the opportunities and long-term returns. Therefore, supports for innovations applied to products intensive in natural resources can be a great opportunity for countries like Brazil.

BASTOS, D.V. Etanol, Alcoolquímica e Biorrefinarias. BNDES Setorial, Rio de Janeiro, n. 25, p. 5-38, mar. 2007.

BOMTEMPO, J. V. Biocombustíveis, bioprodutos e bioprocessos no contexto do desenvolvimento da Química Verde. Química verde no Brasil: 2010-2030. Centro de Gestão e Estudos Estratégicos (CGEE). Brasília, DF: 2010.

BOMTEMPO, J. V. e CHAVES, F. Innovation dynamics in the biobased industry. Chemical and Biological Technologies in Agriculture. SpringerOpen Journal. 2014. Disponível em: http://www.chembioagro.com/content/1/1/19.

BON, E. e FERRARA, M. Bioethanol production via Enzimatic Hydrolysis of Cellulosic Biomass. Paper presented at FAO seminar "The Role of Agricultural Biotechnologies for Production of Bioenergy in Developing Countries". FAO Headquarters, Rome, 2007. Disponível em: http://www.fao.org/biotech/docs/bon.pdf

BONOMI, A. Workshop hidrólise de material lignocelulósico. In CORTEZ, L. A. B. (org) Bioetanol de cana-de-açúcar: P&D para produtividade e sustentabilidade. Blucher, São Paulo, 2010a.

CGEE. Bioetanol combustível: uma oportunidade para o Brasil. Centro de Gestão e Estudos Estratégicos (CGEE). Brasília, 2009.

CORTEZ, L. A. B. (org) Bioetanol de cana-de-açúcar: P&D para produtividade e sustentabilidade. Blucher, São Paulo, 2010.

DASHTBAN, M.; SCHRAFT, H. and QIN, W. Fungal Bioconversion of Lignocellulosic Residues; Opportunities & Perspectives. International Journal of Biological Sciences. vol. 5, n. 6, pp. 578-595, 2009.

DOE. Current State of the U.S. Ethanol Industry. U.S. Department of Energy (DOE) – Office of Biomass Programs. Fulfillment of Subcontract No. 02-5025. November 30, 2010.

EGGERT, H.; GREAKER, M. and PORTTER, E. Policies for second generation biofuels: Current status and future challenges. Statistics Norway, Oslo–Kongsvinger, June, 2011.

FRANCO, T. e GARZÓN, C. Novas possibilidade de negócios do setor sucroalcooleiro: alcoolquímica e biorrefinaria. In CORTEZ, L. A. B. (org) Bioetanol de cana-de-açúcar: P&D para produtividade e sustentabilidade. Blucher, São Paulo, 2010.

FULLER, J. Cellulosic Biofuel and the Government Role in Enabling Complex Innovation. In SAREWITZ, D. ed. The Rightful Place of Science: Government & Energy Innovation. Tempe, AZ: Consortium for Science, Policy and Outcomes. 2014.

GOLDEMBERG, J. The Role of Biomass in the World's Energy System. In Marcos S. Buckeridge e Gustavo H. Goldman. Routes to Cellulosic Ethanol. Springer. New York, 2011.

HIGAM, P. e SINGH, A. Production of liquid biofuels from renewable resources. In Progress in Energy and Combustion Science. vol.37, pp. 52 – 68, 2011.

IDB – INTERAMERICAN DEVELOPMENT BANK. A Blueprint for Green Energy in the Americas Strategic Analysis of Opportunities for Brazil and the Hemisphere Featuring. The Global Biofuels Outlook 2007. Washington, 2007.

IEA. Sustainable Production of second-generation biofuels potential and perspectives in major economies and developing countries. Information Paper. OECD/IEA. Paris, 2010.

LUQUE, R.; HERRERO-DAVILA, L.; CAMPELO, J.; CLARK, J.; HIDALGO, J.; LUNA, D.; MARINAS, J. and ROMERO, A. Biofuels: a technological perspective. Energy & Environmental Science. vol. 1, pp. 542–564, 2008.

MELAMU, R e BLOTTNITZ, H von. 2nd Generation biofuels a sure bet? A life cycle assessment of how things could go wrong. Journal of Cleaner Production. vol. 19, pp 138 e 144, 2011.

PEDRO, E. S. Estratégias para a organização da pesquisa em cana-de-açúcar: uma análise de governança em sistemas de inovação. Tese (doutorado). Universidade Estadual de Campinas, Instituto de Geociências. Campinas, 2008.

PEREIRA JUNIOR, N. Biorrefinarias - Rota Bioquímica. Química verde no Brasil: 2010-2030. Centro de Gestão e Estudos Estratégicos (CGEE). Brasília, DF: 2010.

RODRIGUES, A. H. Três patamares tecnológicos na produção de Etanol: a Usina do Proálcool, a Usina atual e a Usina do futuro. Tese de Doutorado – Universidade Federal Rural do Rio de Janeiro, 2006.

ROSILLO-CALLE, F. Alimentos versus combustíveis: podemos evitar o conflito? In CORTEZ, L. A. B. (org) Bioetanol de cana-de-açúcar: P&D para produtividade e sustentabilidade. Blucher, São Paulo, 2010.

SIMS, R.; TAYLOR, M.; J SADDLER, J. and MABEE, W. From 1st to 2nd Generation Biofuel Technologies. OECD and IEA - International Energy Agency - Bioenergy. November, 2008.

SOUZA, L. G. A. Redes de inovação em etanol de segunda geração. Tese de doutorado. Escola Superior de Agricultura "Luiz de Queiroz". Universidade de São Paulo. Piracicaba, 2013.

SOUZA-AGUIAR, E. F. e SILVA, A. J. G. Biorrefinarias - Rota termoquímica. Química verde no Brasil: 2010-2030. Centro de Gestão e Estudos Estratégicos (CGEE). Brasília, DF: 2010.

VALDES, C. Brazil's Ethanol Industry: Looking Forward. Report from the Economic Research Service. Bio-02.USDA, Washington, June 2011.

VARRICHIO, P. Uma análise dos condicionantes e oportunidades em cadeias produtivas baseadas em recursos naturais: o caso do setor sucroalcooleiro no Brasil. Tese de doutorado. Departamento de Política Científica e Tecnológica - UNICAMP. Campinas (SP). 2012.

1. PhD in Public Policies and Professor of economics at Federal University of Parana (UFPR). His areas of research include: industrial economics, energy economics, biofuels, agriculture and international trade. E-mail: wdspereira@yahoo.com.br

2. PhD in Economic and Senior Professor in the Graduate Program in Public Policies at Federal University of Parana (UFPR). His areas of research include: agriculture, international trade, food security and industrial economics. E-mail: nilson@ufpr.br