HOME | ÍNDICE POR TÍTULO | NORMAS PUBLICACIÓN

HOME | ÍNDICE POR TÍTULO | NORMAS PUBLICACIÓN Espacios. Vol. 37 (Nº 17) Año 2016. Pág. 13

Eduardo Guilherme SATOLO 1; Laiz Eritiemi de Moura HIRAGA 2; Lucas Furlani ZOCCAL 3; Gustavo Antiqueira GOES 4; Wagner Luiz LOURENZANI 5

Recibido: 25/02/16 • Aprobado: 22/03/2016

ABSTRACT: The Lean Production System has been adopted by various organizations that seek to improve their production processes through the waste elimination. However, agribusiness organizations are poorly explored in literature about Lean philosophy application. Thus, this article aims to evaluate the Lean Production System in a laying poultry farm. As a research method, a case study was conducted with the application of interviews, on-site visit and observation, which resulted in the triangulation of information obtained. As a result it was identified that the farm owns the Lean system actions, even though they are unfamiliar with this. |

RESUMO: Portugués Inglés Español O sistema de produção enxuta tem sido adotado por várias organizações que buscam melhorar seus processos de produção através da eliminação de resíduos. No entanto, organizações de agronegócio são mal exploradas na literatura sobre a aplicação da filosofia Lean. Assim, este artigo tem como objetivo avaliar o sistema de produção Lean em uma granja postura. Como um método de pesquisa, foi realizado um estudo de caso com a aplicação de entrevistas, visita in loco e observação, o que resultou na triangulação das informações obtidas. Como resultado foi identificado que a fazenda possui o Lean ações do sistema, mesmo que eles não estão familiarizados com isto. |

The agribusiness, according to Zylberstajn (2013), was created to designate the inseparable connection between the agricultural production activity and industrial activity, both the inputs to it addressed, either to the processing of production it has generated. In 2014, year in which the exported volume and average prices in dollar presented, respectively, a small decrease of 6% and 1% compared with 2013, the agribusiness sector was responsable for generating a $98 billion revenue in exportation in the Brazilian economy, contributing to the surplus of trade balance in approximately $80 billion (Cepea, 2014).

Such importance of this sector carries the need for continuous organizational improvement, resulting in competitive gains in a global market where there is the need for continuous search for the optimization of organizational processes. Various management models, philosophies and management strategies have been developed over the past decades in order to achieve a more effective system. One of these management models which presents major highlight is the Lean Production System.

Lean Production, which has as its origin the Toyota Production System, recommends the constant pursuit of perfection through continuous organizational improvement and is supported by a set of techniques and tools that help on analysis, monitoring, control and management of various organizational aspects of production in order to reduce and eliminate waste in the production system.

Studies on Lean Production Systems in literature are diverse and wide, but not for the agribusiness sector. In a recent survey, Hiraga, Zoccal and Satolo (2014) identified six Brazilian publications that relates the implementation of Lean Production systems with the agribusiness sector. It was further observed that two of these studies have similar characteristics to metal-mechanic sector, being focused on equipment suppliers companies, with four cases portraying the processing of agricultural products.

Such a survey carried by the authors, although restricted to Brazilian researches, portrays the lack of studies in national scenario.

In this context of uncertainty about the current stage demonstrating the applications of Lean Production systems by the agribusiness sector, this article aims to report a case study relating the use of philosophy, techniques and tools of Lean Production Systems in a laying poultry farm.

The poultry industry is one of the most important elements of national and international agribusiness. With a production of 34,730 million units of eggs, corresponding to 4% of world production, the domestic production of eggs has been increasing in recent years, having occupied in 2012 the seventh global placement (Anualpec, 2014).

The quality of eggs and technological investment in the sector have been showing the development of the poultry industry that is symbol of growth and modernization of agribusiness in Brazil. According to data from Brazilian Yearbook of Poultry and Swine Industry in his last published edition, it was shown that in 2012 the export of national product reached 26,800 tons, which represents an increase of 61.2% compared to 2011 and with revenues of $42.6 million.

Besides obtained economic returns, it is worth mentioning the paradigm change regarding the consumption of eggs in Brazil. According to data from Uba (2014), the annual per capita consumption in Brazil has increased from 149 to 170 eggs between 2010 and 2013, representing an increase of 4.5% per year. However, the consumption is low when compared to other countries, such as Mexico, with a consumption of 374 eggs per capita per year (Uba, 2014). Yet, this slight increase demonstrates an upward trend for the coming years, especially because of the campaigns aimed at promoting consumption of eggs (nutritious and healthy) and also the replacement of egg in diet as an alternative protein with a better cost and benefit relation (Mendes, 2014).

These data show the importance of the laying poultry segment in Brazil and the great potential for growth. It is therefore up to study and assess how are the production management practices in these industrial settings, which have their own characteristics, but which are nonetheless facing a competitive and fierce market.

This article is divided into five sections to present the results. This first section presents the research contextualization and the gap holding up its achievement. The second section theoretically based three central topics of this research concerning Lean Production systems, the characteristics of an agribusiness production system and the national sector of egg production. The third section presents the research method and its stages. The fourth section reports the conducion of this case study. Finally, the article ends with the fifth section presenting the conclusions and perspectives for future works.

The Lean Production System has a philosophy that aims to identify and minimize or phasing out sources of waste based on five key principles: the definition of (i) value from the customer view and their needs, that determines (ii) the value chain, which are required activities to offer the product to the customer with the lowest level of wastage. Then the product is manufactured using a (iii) continuous flow, which is triggered only when the client performs the request. That is, using the logic of (iv) pull production. Based on these four principles and the use of continuous improvement (kaizen) or radical improvements (kaikaku) the fifth fundamental principle is reached, which is the (v) system perfection (Calarge et.al. 2012).

These waste minimization or elimination (MUDA in Japanese) are crucial for companies to optimize their activities and to eliminate times and processes that do not add value and are classified into seven types, namely: overproduction, waiting, transportation, motion, over processing, rework and inventory (Vinodh, Somanaathan, Arvind, 2013).

However, the creation of the Lean Production System has gone at the end of the Second World War, when the Japanese industry had to rethink their production model, appearing then the Toyota Production System (TPS) that, due to the shortage of productive resources, sought to produce with the lowest possible cost, especially by combating the so-called wastage (Singh, Singh, 2015).

But the term Lean Production has been defined in late 1980s in a research project at Massachusetts Institute of Technology (MIT), which studied the global automotive industry, with the main focus on the Japanese Toyota model in order to map out the best industry practices, by means of interviews with employees, trade unionists and government officials (Lucato et. al. 2014).

The adoption of the Lean Production System is also the target of studies by several authors proposing studies to report the steps of its implementation and methods to ensure their success through a structured conduction of the entire process.

After 20 years studying the Toyota Production System, Liker (2007) is one of the largest reference work when referred to the implementation of this system. During this period, Likert identified 14 management principles that drive the Lean Production techniques and tools.

These principles, according to Liker (2007), can be grouped into four main categories for organizational assessment, as follows: philosophy category covers the principle 1; the process category covers principles from 2 to 8; the employees and partners category includes from 9 to 11; and problem solving category includes the principles from 12 to14, all described in Table 1.

Table 1 – The 14 principles for evaluation of the Toyota Production System implementation.

Categories |

Principles |

Description |

Philosophy |

Principle 1 |

To base management decisions on a long-term philosophy, even at the expense of short-term financial goals. |

Process |

Principle 2 |

To create a continuous process flow to put problems in evidence. |

Principle 3 |

To use pull systems to avoid overproduction. |

|

Principle 4 |

To level the workload. |

|

Principle 5 |

To build a culture of stopping and solving problems to obtain the desired quality on the first try. |

|

Principle 6 |

Standardized tasks are the basis for continuous improvement and employee training. |

|

Principle 7 |

To use visual control so that no problems are hidden. |

|

Principle 8 |

To use only reliable and fully tested technology that meets the needs of employees and processes. |

|

Employees and partners |

Principle 9 |

To develop leaders who completely understand the work, really live up the philosophy and teach others. |

Principle 10 |

To develop exceptional people and teams who follow the company's philosophy. |

|

Principle 11 |

To respect its partner and suppliers network by challenging them and helping them to improve. |

|

Problem Solving |

Principle 12 |

To see by yourself to fully understand the situation. |

Principle 13 |

To take decisions slowly by consensus, thoroughly considering all options; implementing them quickly. |

|

Principle 14 |

To become a learning organization through a tireless reflection and continuous improvement. |

Source: Liker (2007)

The implementation of Lean Production system in organizations uses various techniques and tools, which should take place in a coordinated and structured way (Pettersen, 2009); (Hunter, 2004). These techniques and tools assist this process of minimization or waste elimination by bringing results such as: reducing lead times, cost savings, quality improvement and increased productivity, making them agile and more competitive (Walter, Tubino, 2013); (Saurin et. Al. 2010). Thus, these techniques and tools are a valuable aid in improving a product or process in a wide variety of organizations (Feld 2001).

Walter and Tubino (2013) gathered in a single material 48 papers from national and international literature published between 1996 and 2012, and noted the usage frequency of Lean Production techniques and tools by organizations in various sectors of the economy, as highlighted in Table 2.

Table 2 - Frequency approach of the techniques and tools of Lean Production System

Techniques and Tools |

Use frequency |

Voice of the Customer (VOC) |

0.0 |

Single Minute Exchange of Die (SMED) |

68.7 |

Group Technology (GT) / Cellular manufacturing |

37.5 |

Takt Time |

0.0 |

Marketplace |

0.0 |

Pull Production and Continuous Flow |

75.0 |

Work Standardization |

33.3 |

Production Leveling |

25.0 |

Kaizen |

31.2 |

Value Stream Mapping (VSM) |

35.4 |

Total Productive Maintenance (TPM) |

50.0 |

Economic order quantity |

0.0 |

Kanban |

0.0 |

Supply Chain Integration |

60.4 |

Heijunka Box |

0.0 |

Visual Management |

43.7 |

Multifunctional workforce |

58.3 |

FIFO |

0.0 |

Team Development |

39.6 |

Lean Suppliers (JIT) |

22.9 |

Concurrent engineering |

16.7 |

Six Sigma/DMAIC |

0.0 |

Poka-Yoke (Error Proofing) |

0.0 |

Cause and Effect Diagram (Ishikawa Diagram) |

0.0 |

Statistical Process Control (SPC) |

22.9 |

Total Quality Management (TQM) / Zero Defects |

58.3 |

Autonomation / Jidoka |

18.7 |

5S/8S |

39.6 |

Source: Adapted from Walter and Tubino (2013).

Among 28 such tools and techniques commonly assigned to Lean Production System, Walter and Tubino (2013) identified 18 and five of which that are evidenced: Pull Production and Continuous Flow; Single Minute Exchange of Die (SMED); Supply Chain Integration; Total Quality Management (TQM) and Zero Defects; Multifunctional workforce.

The agribusiness production system, according to Watanabe and Zylbersztajn (2011), is constantly changing along with its concept. Thus, the agribusiness system concentrates its study to examine the relationships between the different players in a chain in order to design business strategies and public policies. However, regardless of the system diversity, the focus of this paper is centered on possibility of the projection of business strategies.

Batalha and Silva (2008) points out that much of the modern management tools have been developed for sectors other than the agribusiness. This may be the reason why there are difficulties to implant the techniques and tools, as well as a resistance on the researchers side to adapt, implement and analyze the use of these in agribusiness environments.

Authors from agribusiness sector demonstrate which are the specificities of the agribusiness production systems and these are highlighted in Table 3.

Table 3 - Specificities of the agribusiness production systems

Specificities |

Authors |

||

Batalha and Silva (2008) |

Zuin and Queiroz (2006) |

Araujo (2013) |

|

Seasonal availability of raw materials |

X |

X |

X |

Quality variations of raw materials |

X |

X |

|

Perishability of raw materials |

X |

X |

X |

Consumption seasonality |

X |

X |

|

Perishability of final products |

X |

X |

X |

Quality and health surveillance |

X |

X |

|

Sociological aspects of foods |

X |

X |

|

Biological and edaphoclimatic conditions of foods |

|

X |

X |

Impact of cross-sectional technologies such as biotechnology |

X |

|

|

Production dispersion |

|

|

X |

Low added value of agricultural products |

|

|

X |

Source: Prepared by the authors.

The authors of this research also adds another specificity not highlighted in Table 3. It is about the number of raw materials suppliers. Every organization requires raw materials, which serve as inputs in the productive system and which are transformed in the processes to generate the goods. Many of agribusiness segments have a large number of raw materials suppliers, such as the segments of: milk, meat, sugarcane, rubber, soybeans, among others. This brings a high degree of difficulty for management and integration of these suppliers with the agribusiness.

The laying poultry farm has been taking an important role in the national socio-economic context. By being a low cost animal protein, the eggs have been increasingly consumed by the Brazilians (Uba, 2014).

Technological development in egg production has become reality with the development of techniques to achieve higher productivity at the lowest cost (Kakimoto, 2008). Thus, the food, nutrition, sanity, environment and management must be harmonized in order to facilitate the full potential expression of commercial laying hens (Augusto, Kunz, 2009).

The bigger producers of eggs are vertically integrated backwards, featuring several production units, feed factory, raising chickens and eggs factory (Martins, 1996). This results in that producers are mostly independent by performing the preparation of their own feed and working with traditional open sheds. However, the gap between small and large poultry farmers are notorious when it comes to the automation of egg production (Covre, Fassarela, 2010).

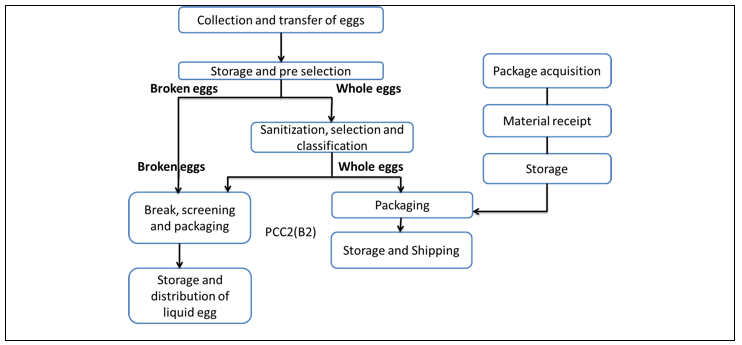

The small poultry farmers still perform activities such as the collection of eggs and distribution of the feed manually and in rudimentary sheds. In contrast, there are big producers whom are choosing for climate adaptation and facilities automation, owning automated plants with electrical classification that, by sensors, grade and pack eggs decreasing waste and consequently costs (Donato et. al., 2009); (Covre, Fassarela, 2010). Nevertheless, regardless of size, the process steps of the egg production (Figure 1) are similar in any factory, diverging only in certain aspects, for example, the implementation of technology and automation.

Figure 1 - Flow Chart of egg production system

Source: EMBRAPA (2004)

The egg production system illustrated in Figure 1 can be described as follows (EMBRAPA, 2004):

This study aims to examine contemporary events in a real and recent context, in which relevant behaviors can not be manipulated and so far have not been clearly defined in literature. Furthermore, there are more variables of interest to be investigated than data to be collected, thus characterizing as a case study (Yin, 2010); (Miguel, 2011).

Considering the purpose of the research, this study has the characteristic of a case study as a theory construction, since identifies and describes the key variables, highlighting the links and the reasons for the relationship between the studied variables (Voss et. al., 2002). Typically, this kind of research is based on application of questionnaires in order to perform a triangulation, in other words, the use and combination of different methods to study the same phenomena. To validate the triangulation process it was also used the on-site visit, the observation and the document analysis (Voss et al., 2002.); (Miguel 2011).

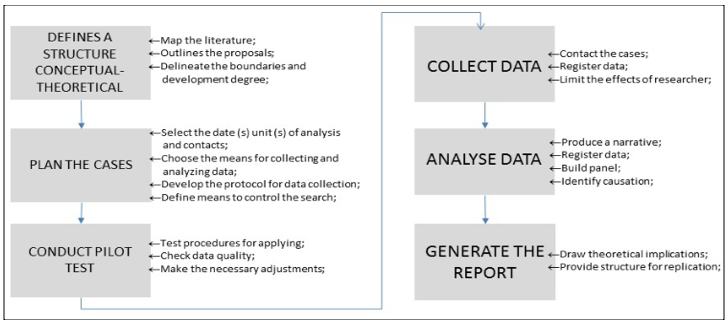

According to Miguel (2011), the conduction of a case study occurs through six main steps which have been adopted for this work. These steps are illustrated in Figure 2 and will be detailed on the results topic of this work.

The selection of the case study in this work was restricted to poultry farms located in State of São Paulo, which accounts 26.5% of national production of eggs. In particular, the city of Bastos stands out in national and state scenario representing 8% and 30%, respectively, of egg production. Known as "national capital of the egg", Bastos had in 2013 a production increase between 10% and 13%, with 190 eggs per second. This advantage was mainly generated by the automation of poultry farms and the modernization of its eggs processing rooms, reflecting in higher productivity and quality of eggs (Avisite, 2014).

Figure 2 - Steps for the case study conduction

Source: Miguel (2011).

Table 4 provides some comparative data that recall the importance of State of São Paulo and the city of Bastos in the laying poultry farm segment.

Table 4 - Brazil, State of São Paulo and the city of Bastos: Commercials Eggs Production, from 2010 to 2013- Quantity of chicken eggs (thousand dozens)

Region |

Year |

Percentage variation (2010-2013) |

|||

2010 |

2011 |

2012 |

2013 |

||

Brazil |

3,246,719 |

3,394,224 |

3,473,021 |

3,619,217 |

11.0 |

Southeast |

1,422,915 |

1,437,147 |

1,472,627 |

1,533,169 |

7.0 |

São Paulo |

867,652 |

881,445 |

897,755 |

959,408 |

11.0 |

Bastos |

213,851 |

226,026 |

235,863 |

288,408 |

35.0 |

Representativeness Bastos/Brazil (%) |

6.6 |

6.7 |

6.8 |

8.0 |

21.2 |

Representativeness Bastos/São Paulo (%) |

24.6 |

25.6 |

26.3 |

30.1 |

22.1 |

Source: IBGE, Research Board, Agricultural Coordination, Research of Municipal Cattle 2010, 2011, 2012 and 2013.

Founded more than 50 years ago and currently being under the control of the second generation of the family, the Research Unit is a traditional company that produces eggs in the city of Bastos. It has recognized quality of eggs produced, which received awards in various editions of Egg Quality Contest.

Among its principles can be highlighted investments in quality, technology, sanity, poultry nutrition and processes automation. Currently, it has around one million laying hens producing nearly 600,000 eggs per day, which corresponds to 7.6% of the total production of the city of Bastos. To manage the whole process, the Research Unit has approximately 35 employees (considered as a small business).

The interview was carried out with the plant manager, responsible for the production management of the company (brood chicks, agricultural and industrial). Beyond the interview (lasting about 1h45), observations were conducted through on-site visit and documental analysis, which allowed the triangulation of information.

Based on this set of information it was generated the Figure 3 which depicts the perception of the application level of each Lean principle, from the foregoing by Liker (2007).

Figure 3 - Graphical representation of the Research Unit performance for each Lean Production System principle

|

Legends: 1 – Does not perform 2 – Has informal initiatives 3 – Performs in an informal manner 4 – Performs formally, but with pending 5 – Performs formally |

Source: Prepared by the authors.

This perception of application level of Lean Production System principles is justified by the actions performed and the limitations presented by the Research Unit, described in Table 5.

Table 5 – Explanations about the perceptions of application level of Lean Production System principles

Principles |

Explanations |

1 |

- Daily monitoring of eggs prices (short and medium term forecast). - Implementation of improvements into the production process (machines and technologies). - Compliance withcurrent health and ergonomic regulations. - Improvement of working conditions (suitable and comfortable environment). - Incentives for campaigns aimed at promoting the egg comsuption jointly with other producers and institutions. |

2 |

- Continuous flow process. - Periodicals preventive maintenance. |

3 |

- Contracts traded on futures market. - Pulled Production considering planned sales. - Forecast of eggs to produce, through feed control (called a forced molting). |

4 |

- Workload leveling. - Employees are involved in part of the process, since every "heavy" process is automated. |

5 |

- Problems solved immediately. - There are uncontrollable situations with biological assets (the hens), at this stage it can be seen a higher incidence of corrective maintenance. |

6 |

- Tools used for visual control were not identified. |

7 |

- Use of sophisticated equipment in quality management and visualization of product failure. - Use of candling (x-ray), programmed to identify nonstandard eggs. - Simple operation controls of machines for employees. |

8 |

- Employees are trained and qualified to carry out the activities completely. |

9 |

- There were no actions on this principle. |

10 |

- Management policies with customers and suppliers. |

11 |

- Commitment to comply deadlines and contracts agreed with customers and suppliers. - Fidelity and security relationship with the suppliers services, ensuring quality and reliability of the acquired product. |

12 |

- Resolutions first run from employee. - Valuing the intellectual capital of the employee whom can solve small problems. - Situation unsolved by the employee is reported to the owner immediately. |

13 |

- Decisions based on the organization's financial capacity to implement improvements. - It is previously studied any proposal to the productive efficiency of the research unit, but always respecting the limitations of the unit. |

14 |

- There are visible willingness to maintain continuous improvement in all process steps. - There are motivation to keep the family tradition, focusing on modernization and expansion of new markets. |

Source: Prepared by the authors.

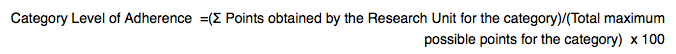

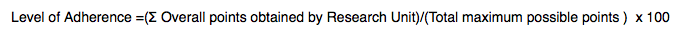

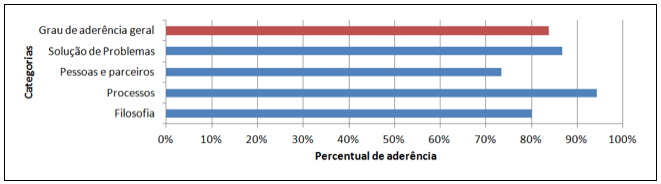

Based on these informations, by means of Equation 1, it is possible to establish the level of adherence of the Lean Production System for each category established by Liker; and the level of final adherence, by means of Equation 2, as illustrated in Figure 4.

Equation 1

Equation 1

Equation 2

Equation 2

Figure 4 – Level of adherence of Research Unit to the Lean Production system (by category and overall)

Source: Prepared by the authors.

Regarding to the Lean Production System principles described by Liker and used to evaluate the Research Unit, it is noted that in philosophy category (includes the principle 1), the Research Unit has good initiatives, but there is a certain shortage of the completing of long-term thinking, being a limitation, since the decisions are based on requirements and not by strategies.

Regarding to process category, a large number of actions are carried out and evidenced by good indexes obtained on the principles 2, 3, 4, 6 and 8. However, it is noted that there is still room for improvement, especially on the principles 5 and 7, in which currently there are no actions being carried out by the Research Unit.

In employees and partners category, we can see a satisfactory level of integration with suppliers and also a leadership development (principle 11). However, with respect to creation of leaders whom assimilate and are inspired by the Lean philosophy, there were no actions identified in this direction (principle 9).

Finally, in troubleshooting category, it is noted that the same is done in an informal manner and by the person responsible for the sector. But the organization already started actions to make the continuous improvement process a practice in the organization.

Concerning the use of Lean Production techniques and tools, the Research Unit employs a set of six, and four of them are focused on the process (Lot sizing, poka yoke, pull production, autonomation/jidoka). Such fact highlights the good performance in this category by the Research Unit. The other two tools are: suppliers' integration and empowerment.

About the specificities of agribusiness production system, cited by Battle and Silva (2008), the laying poultry system analised in this study suffers important influences on some items described in Table 6.

Table 6 - Influence of the specificities on agribusiness production system of laying poultry

Specificity |

Influence on agribusiness production system of laying poultry |

Seasonal availability of raw materials |

The feeds, one of the major raw materials, has a high percentage representativeness in the total cost of production and is impacted by fluctuations in costs of corn and soybeans. |

Consumption seasonality |

There is a strong decrease in consumption in special party periods (Easter, New Year, Christmas) and also in school holiday periods. |

Perishability of final products |

Highly perishable product which can not be stored, but when marketed the expiration date of the egg is 21 days, keeping it properly refrigerated. |

Quality and health surveillance |

High impact factor due to the risks and dangers that this activity includes, such as bacteria (Salmonella), contamination by hens' feces or by the handlers and plagues. |

Sociological aspects of foods |

Continuous work in order to change the paradigm of the eggs consumption, change in eating habits, demystification on eggs' cholesterol and others. |

Biological and edaphoclimatic conditions of foods |

Strong key factors in the results are the need for bacteria and plagues control, beyond the control of the environment in which hens live. |

Source: Prepared by the authors.

This case study aimed to describe how Lean Production principles are being applied in an agribusiness system of laying poultry and allowed to glimpse some important considerations on this topic.

It was noted that the principles of Liker (2007) were essential for carrying out the survey and mapping of information that guided this research. Such fact is justified because the proposal of the author does not restrict its use to units that have formalized the Lean Production System in its organizational environment.

The research unit has demonstrated that even, theoretically, not knowing the Lean Production principles, carries out activities of the method.

Overall, the research unit has a good adherence level to the Lean thinking and practices (84%), having as emphasis on its organizational environment the principles associated to problem solving and to processes categories. The organization needs to formalize, largely, the initiatives already undertaken to improve the indicators related to this process.

Regarding to Lean philosophy, the organization already has well underway the process of diffusion of his thinking, fitting for upper management carry out the process of formalization of this practice in its organizational environment.

By having a highly verticalized process, the research unit has no actions being developed with suppliers, which is one of the reasons for the low score in the relative principle (10), but there are actions in order to disseminate the Lean philosophy in the organizational environment and therefore the development of new leaders may be carried out to improve performance of suppliers and persons categoriess.

It has been found also that aspects related to the specificities of agribusiness production systems affect the organization, such as seasonal availability of raw materials, consumption seasonality, perishability of final products, quality and health surveillance, sociological aspects of foods and biological and edafoclimatic conditions of foods.

Some of problems on these characteristics can be resolved by the use of Lean Production techniques and tools that have not been applied by the research unit, such as statistical process control, production leveling and total quality management.

Finally, it is highlighted that the Research Unit, although already perform not formalized actions that impact the minimization and elimination of losses in its various production aspects, still has a wide margin of improvement that can be achieved through the Lean philosophy. For this purpose, the organization can perform a formalization of Lean Production system and use the various tools and techniques widespread in literature in order to improve the principles of Liker (2007). Hence, the organization can better manage the impacts brought by specificities of the agribusiness production systems that operate on the Research Unit.

Acknowledgements

Research grants awarded: Process number 2013/21047-5, Support Foundation of São Paulo (FAPESP), Process number 2014/04329-0, Support Foundation of São Paulo (FAPESP) and PROPe - Pro Rectory of Research - UNESP.

ANUÁRIO BRASILEIRO DE AVES E SUÍNOS (2013); Editora Gazeta. Santa Cruz do Sul- RS. ISSN 1808-7507.

AVISITE [Publicado 16 julho 2014]. Disponível em: http://www.avisite.com.br/clipping/?codclipping=23729.

ANUALPEC- Anuário estatístico da pecuária brasileira (2014); São Paulo: FNP Consultoria & Comércio.

ARAUJO, M.J. (2013); Fundamentos de agronegócios, São Paulo: Atlas, 4 ed.

AUGUSTO, K.V.Z.; KUNZ, A. (2009); Tratamento de dejetos de aves poedeiras comerciais. Disponível em: http://www.alice.cnptia.embrapa.br/bitstream/doc/ 920821/1/tratamentodedejetosdeaves.pdf.

BATALHA, M.O; SILVA, A.L. (2008); Gerenciamento de sistemas agroindustriais: definições, especificidades e correntes metodológicas. Gestão agroindustrial. São Paulo, Atlas, v.1, 1-62 p.

CALARGE, F.A.; SATOLO, E.G.; PEREIRA, F.H.; DIAZ, E.C. (2012); "Evaluation of Lean Production System by using SAE J4000 standard: Case study in Brazilian and Spanish automotive component manufacturing organizations", African Journal of Business Management, v. 6, n.49, 11839-11850 p.

CEPEA - Centro de Estudos Avançados em Economia Aplicada - ESALQ/USP. (2014); Faturamento e volume exportado do agronegócio brasileiro são recordes em 2013. Disponível em: http://www.cepea.esalq.usp.br/comunicacao/Cepea_ExportAgro_2013.doc.

COVRE, J. ; FASSARELLA, R. A. (2010); Estudo da cadeia produtiva da avicultura de postura no município de Santa Maria de Jetibá no Estado do Espírito Santo. Congresso Da Sociedade Brasileira De Economia, Administração E Sociologia Rural, 48.

DONATO, D.C.Z.; GANDRA, E.R.S.; GARCIA, P.D.; REIS, C.B.; GAMEIRO, A.H. (2009); A questão da qualidade no sistema agroindustrial do ovo. Congresso da sociedade brasileira de economia, administração e sociologia rural, 47.

EMBRAPA. (2004); Manual de segurança e qualidade para avicultura de postura. Brasília.

FELD, W. M. (2001); "Lean manufacturing: tools, techniques, and how to use them". CRC Ed.

HIRAGA, L.E.M.; ZOCCAL, L.F.; SATOLO, E.G. (2014); Aplicações do conceito Lean Production no agronegócio brasileiro: um levantamento do estado da arte e perspectiva de trabalho futuros. Encontro Nacional De Engenharia De Produção, XXXIV, Curitiba.

HUNTER, S.L. (2004); "Ten Steps to Lean Production". FDM Management, 20-23 p.

IBGE - Instituto Brasileiro de Geografia e Estatística Sistema IBGE de Recuperação Eletrônica (SIDRA) - Ovos de galinha, (2015). Disponível em: http://www.sidra.ibge.gov.br/bda/pecua/default.asp?t=7&z=t&o=24&u1=1&u2=1&u3=1&u4=1&u5=1&u6=1&u7=1.

KAKIMOTO, S.K. (2008); Evolução tecnológica na avicultura de postura. XXVIII Encontro Nacional De Engenharia De Produção. Rio de Janeiro.

LIKER, J. K. (2007); O modelo Toyota: 14 princípios de gestão do maior fabricante do mundo. Porto Alegre: Bookman.

LUCATO, W.C.; CALARGE, F.A.; MAURO, L.J.; CALADO, R.D. (2014); "Performance evaluation of lean manufacturing implementation in Brazil". International Journal of Productivity and Performance Management, v. 63, n. 5, 529-549 p.

MARTINS, S.S. (1996); Cadeias produtivas do frango e do ovo: avanços tecnológicos e sua apropriação. Escola de Administração de empresas de São Paulo da Fundação Getúlio Vargas. Disponível em: http://bibliotecadigital.fgv.br/dspace/handle/10438/4629.

MENDES, L.H. Consumo per capita de ovos no Brasil crescerá 9% em 2014. [Publicado 07 outubro 2014]. Disponível em: http://www.valor.com.br/empresas/3725414/consumo-capita-de-ovos-no-brasil-crescera-9-em-2014.

MIGUEL, P.A.C. (2011); Metodologia de pesquisa em engenharia de produção e gestão de operações, São Paulo: Elsevier, 2 ed.

PETTERSEN, J. (2009); "Defining lean production: some conceptual and practical issues". The TQM Journal, v.21, n. 2, 127-142 p.

SAURIN, T.A.; RIBEIRO, J.L.D.; MARODIN, G.A. (2010); Identificação de oportunidades de pesquisa a partir de um levantamento da implantação da produção enxuta em empresas do Brasil e do exterior. Gest. Prod., São Carlos, v. 17, n. 4, 829-841 p.

SINGH, J.; SINGH, H. (2015); "Continuous improvement philosophy-literature review and directions". Benchmarking: An International Journal, v. 22, n. 1.

UBABEF- União Brasileira de Avicultura. Relatório anual 2014. Disponível em http://www.ubabef.com.br/files/publicacoes/8ca705e70f0cb110ae3aed67d29c8842.pdf.

VINODH, S.; SOMANAATHAN, M.; ARVIND, K.R. (2013); "Development of value stream map for achieving leanness in a manufacturing organization". Journal of Engineering, Design and Technology, v.11, n. 2, 129 -141 p.

VOSS, C.; TSIKRIKTSIS, N.; FROHLICH, M. (2002); "Case Research in Operations Management". International Journal of Operations and Production Management, v.22, n. 2, 195-219 p.

WALTER, O.M.F.C.; TUBINO, D.F. (2013); Métodos de avaliação da implantação da manufatura enxuta: Uma revisão da literatura e classificação. Gest. Prod., São Carlos, v. 20, n. 1.

WATANABE, K.; ZYLBERSZTAJN, D. (2011); "Agro-system (ags) as a tool for analysis, taking into account sustainability". BioEng, Tupã, v.5 n.1, 57-74 p.

YIN, R. K. (2010); Estudo de caso: planejamento e métodos. 4. ed. Porto Alegre: Bookman.

ZUIN, L.F.S.; QUEIROZ, T. R. (2006); Agronegócios: gestão e inovação. São Paulo: Saraiva.

ZYLBERSTAJN, D. (2013); Administração de sistemas de base agrícola: análise de fatores críticos. Revista Administração, São Paulo, v.48, n.2, 203-207 p.

1. São Paulo State University, Tupã Campus / Researcher of CEPEAGRO, Professor of the Post-Graduate in Agribusiness and Development. Assistant Professor Doctor of Business Course. Tupã City, São Paulo State, Brazil. E-mail: eduardo@tupa.unesp.br

2. São Paulo State University, Tupã Campus / Researcher of CEPEAGRO, Business student. Tupã City, São Paulo State, Brazil laizhiraga@hotmail.com

3. São Paulo State University, Tupã Campus / Researcher of CEPEAGRO, Business student. Tupã City, São Paulo State, Brazil E-mail: lucaszoccal@tupa.unesp.br

4. São Paulo State University, Tupã Campus / Researcher of CEPEAGRO, Master student in Agribusiness and Development. Tupã City, São Paulo State, Brazil E-mail: gustavogoes@tupa.unesp.br

5. São Paulo State University, Tupã Campus / Researcher of CEPEAGRO, Professor of the Post-Graduate in Agribusiness and Development. Assistant Professor Doctor of Business Course. Tupã City, São Paulo State, Brazil. E-mail: wagner@tupa.unesp.br