1. Introduction

The growing increase world population has generated the need of the greater amount of products and greater speed in its manufacture, craft products of yore already did not satisfy more the demand, and the industrialization, with the advent of Industrial Revolution, came to supply this need. The advance technologic came in a growing development in the form of new machines, new materials and productive processes getting to the levels that will be unimaginable until recently.

The residues from industrial processes that before were practiced, by being in their mostly of natural origin, did not cause great impacts to the environment, since the residues of this new concept of production, with its wide range of ways and compositions reverberated of the violent way, in few decades, in the balance of environmental planet.

Materials developed with focus only in the proprieties need to the application of the final product and in the productive process that aim solely the maximum obtaining profit culminated in refuses of difficult decomposition, high toxicity, among other strange proprieties to the nature, causing the unfolding that occur in the present time: climate change, deserts that do not stop of growing in the in ecosystems.

In this context, Cleaner Production, according to Pimenta and Gouvinhas (2007), present itself as favorable tool to the performance of the companies of preventive way in relation to its environment aspects, through the minimization of impacts associated with cost reduction and optimization process, recuperation and optimization of the use of raw materials and energy, having of general way productivity gains from the preventive environmental control.

Analogous to this the continuous search by the increase productive and organizational efficient, each time more motivated by the incited competition among companies in the current globalized market, makes of the Suggestions Program a key piece for the improvement the organizational performed as a whole. As reported Bonache (1999) the Suggestions Program é a method for training and stimulus to the employer for the creation of ideas that improve the processes, increase the quality and propitiate the cost reduction in the organization.

This article has by the objective to verify how the Suggestions Program with the support of the Cleaner Production can improve the process in a company of the Casting Industry of secondary aluminum, in Ponta Grossa city.

2. Theoretical Reference/ Literature Review

2.1 Cleaner Production

The concept Cleaner Production (CP) appeared in 1991, by the UNIDO/UNEP, as an intermediate approach between the Cleaner Production of Greenpeace and diminution of residues of the Environmental Protection Agency – EPA (CNTL, 2003). Referring itself to the integrated production and environmental protection of wide way, considering all the phases of productive process and the life cycle of final product (PNUMA, 1993).

Barbieri (2004) affirms that the definition of the Cleaner Production (CP) is linked with the definition of clean technology, that should get the intention of disseminate loss pollution to the environment, to generate loss residues and to consume loss nature resources.

According with the National Center of Clean Technology – NCCT (2003), Cleaner Production is the continuous use of an economic, environmental and technologic strategy associate to the processes and products in order to increase the effectiveness in the use of raw materials, water and energy through of not generation, diminution or recycling of residues generated in all productive sectors.

In this paper, is understood as concept of Cleaner Production, a methodology that minimize the pollution to the environment, used as a tool to increase the effectiveness of the products, inputs and services, to improve the use economic, environmental and technologic of the company.

The CP applies a preventive approach in the Environmental management that allows the operation of the company of social way and environmentally responsible, bringing an influence in economics and technological improvement (CNTL, 2001; SILVA FILHO; SICSÚ, 2003), with the intention of maximizing the efficiency in the utilization of the raw materials, water and energy, applied to the services and production, with the intention of increasing the risks for the people and to the environment (CNTL, 2001; SILVA FILHO e SICSÚ, 2003; PIMENTA e GOUVINHAS, 2007).

According with CNTL (2002), this technology (CP) presents several advantages when compared to the technologies of tube end (technologies these that, instead of adopting prevention, concern in remedying the environmental impacts of the residues through of treatment after their generation, only trying to remedy the harm caused), as follows:

- Reduction of amount of material and energy used, presenting thus a potential for economics solutions;

- The minimization of residues, effluents and emissions;

- The responsibility can be assumed for the production processes as a whole and the risks in the fields of environmental obligations and of the residues disposition can be minimized.

The CP has the objective to strengthen economically the industry through of the pollution prevention, collaborating with the progress of the environmental situation of determinate region. It explores all the productive process and evaluates the use of materials and energy. From this, are carefully examined the products, technologies and the materials, with the intention of decreasing the residues, emissions and effluents, and to discover ways of reusing inevitable (CNTL, 2002).

The National Center of Clean Technology (2002), defines that the CP is a complete tool in the determination of choices for the optimization of productive process and the continuous improvement of process. The tool joins the questions that induce to: quality, planning, security, environment, design, Occupational health and efficiency.

The implementation of CP, according Perretti et al. (2007) requires a means of monitoring environmental indicators and process and provides results related to eco-efficient use of resources, leading to a thorough understanding of the company's management.

The implementation of Cleaner Production consists of eighteen goals to be achieved and is described by Diniz (2007) as:

a) Commitment of company management: commitment to the business owner, and the direction from top management is required to perform the work.

b) Awareness of staff: inform all employees about the program's implementation in the company.

c) Training Ecotime: responsible for impregnating the methodology to their classmates and do.

d) Presentation of methodology: in technical meetings, aiming to provide objectives for each phase of deployment of the methodology.

e) Pre-assessment: assessing the environmental licensing of the external and internal.

g) Definition of indicators: defining the indicators to be used by the company.

h) Evaluation of the collected data: critical analysis of information obtained, focusing on the quantity and toxicity of waste generated and raw materials consumed; legal regulations that must be met to use and disposal of materials and waste; costs involved in purchasing, treatment and the possible punishments for the environmental agency.

i) Barriers: lack of effective involvement of the Company; Ecotime had difficulty performing the measurements and to assimilate the concepts and methodology of the PML and the difficulties of getting the measuring equipment (scales).

j) Selection of the focus of evaluation and prioritization of actions: defining the steps, processes, products and / or equipment which will be prioritized for measurement and achievement of effective mass balances and / or energy.

k) Balance of mass and / or energy: general overview; interim balance sheet and balance specific you enter and exit the company.

l) Evaluation of causes of waste generation: Ecotime the question: why? how? when? where? residues are / were generated.

m) Generation of options for improvement: use of production management flowchart for specific evaluation of each level.

n) Assessing the technical, environmental and economic, technical evaluation questions the technical feasibility of implementing each level, environmental assessment, evaluate the environmental benefits to be gained and economic evaluation assesses the economic viability of each of the levels produced.

o) Select the option: assessing needs and identified several options for reducing waste, you choose one that offers the best technical condition, with the highest environmental and economic benefits.

p) Implementation: Implementation must be initiated by the options simpler and less costly.

q) Plan for monitoring and continuity: it aims to maintain, monitor and provide continuity to the program.

2.2 Suggestion Program

Second the Ideas Book (Japan Human Relations Associations – JHRA, p.21, 1997), the concept of Suggestions Program “is the process through of which own solutions are adopted by the management team”. These programs valorize and stimulate the innovative initiative, besides improving the efficiency and competitiveness organizational.

According with Böhmerwald (1996), a Suggestion Program searches improvement to the working conditions and interpersonal relations, for the organizational climate e for the management actions. It increases the productivity, critique vision, commitment of employee and the perception of the company on the importance of the employee, improving thus, the communication company/employee/company.

Suggestion Program owns a simple structure, second Souza and Yonamine (2002), and generally follows the following steps;

- Idea Record: all employees participate individually or in group;

- Analysis of economic and technique viability: the ideas are analyzed for a technique team and are divided in measurable, whose return can be quantified, and immeasurable , where the evaluations are qualitative;

- Awards: the measurable ideas receive awards in value previously stipulated by the company and the immeasurable receive points that can be changed for awards do not founded in the coordination sector.

For the programs that have the monetary recompense as incentive to the suggestions, the rules of awards are calculate according the value proportion that the company predicts to save with implementation of idea. However, programs with the approach turned to the collective participation, the recompenses are symbolic, as for example, stability in the job, distribution of profits and results, opportunities in the personal development, appointments, plate recognition, recompenses collective of merchandises, among other (BARBIERI, ÁLVARES E CAJAZEIRA, 2008).

Thus, all the ideas are sent for approval of a team, and posteriorly, to the manager of the responsible area by the effectuation of idea. In this moment, are analyzed the technical viability of implementation, the financial return and the general benefits provided by the idea. If the proposal is approved, the next step is to reward the employee and implanting the idea (SOUZA e YONAMINE, 2002).

However, a problem appointed by the specialized literature shows that delay in the evaluation of the suggestions can reduce the flow of new ideas. Nevertheless, when this flow is configured in thousands of ideas, the evaluation becomes itself a slow process and delicate. In this point, Suggestion Program creates a paradox, in other words, how to manage a great amount of ideas in the everyday business? This way, the structure of suggestions management becomes dependent of information technologies, as for example, software for managing of the suggestions.

Since there is not a specific model of Suggestion Program, the application needs to be customized to the processes of each company (BARBIERI, ÁLVARES E CAJAZEIRA, 2009).

Basically, software serves as a database where “stores” all the ideas. And as an innovation, the software was created to support the captation process, classification, selection and management of ideas. It allows to control and to manage of agile and safe way, ensuring to organization to register all suggestion in a database. It is an information technology that serves of support for the ideas management that feed the innovation processes.

2.2.1 Example of idea originated from a Suggestions Program

In the company Suzano Paper and cellulose unit of Mucuri, in Bahia, there is a Innovation and Creativity Program denominated Click that stimulates and rewards all the suggestions that bring benefits to the company. It was the first company to receive the certification ISO 14001 in the Americas and the Millennium Environmental Award granted by the ONU in 2000.

In 2006, after a re-structuration the company strengthened the strategy turned for the quality and competitiveness, potentiating programs as six sigma and operational excellence, beaconing the management NQA (National Quality Award).

Click Program appeared in function of the alignment need to the criteria of Excellence of the NQA to disseminate the Innovation Culture and of the intra-entrepreneurship in the generation of ideas for the resolution of problems and to increase the creativity of all employees and to optimize processes improving thus the global development of the company. Being administrated this program, by the competitiveness area from the Suzano that treats of the Management Programs for excellence, Management for Sustainability, Innovation Management, Productivity and Benchmarking.

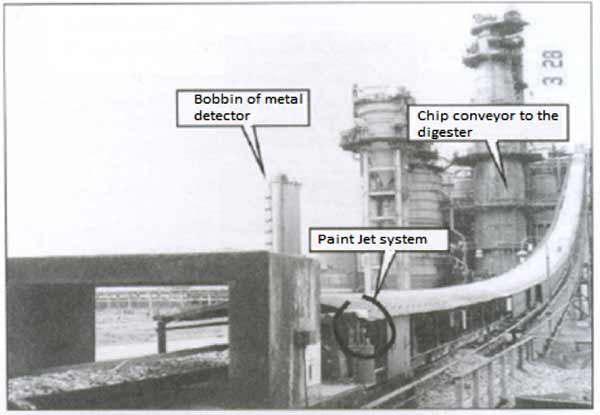

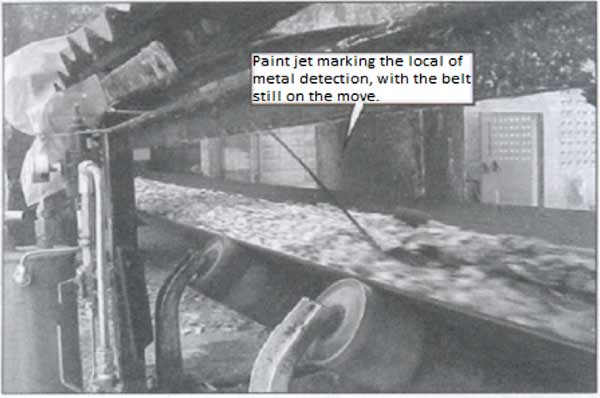

An employee, automation technical, of maintenance management, identified that an operator from area found many difficulty to remove a metal that mixed to the chip on the haulage in time of not to compromise the feeding of the digester. As the difficulty was to find the exact localization of the metal, proposed the creation of the system of paint jet that demarcated the local where was the metal. The figure 1 and 2 represents the process:

Fig. 1 Paint Jet system of the company.

Source: Barbieri, Álvares, Cajazeira, 2009.

Fig. 2 Demarcation of paint jet in the metal with the belt on the move.

Source: Barbieri, Álvares, Cajazeira, 2009.

This new process allowed greater agility of the intervention time and allowed greater security in the identification of the metal mixed to the chip on the conveyor. The system consisted in a fitted cylinder with paint and pressurized to air, made with leftovers of recyclable materials from boiler.

The cost of this process before of this idea to be implanted was R$ 1.591.370,00 (approximately US$ 2.689.415,30) originated of production lost with the stops of digester. This new system, of paint jet, reduced the process cost for R$ 28.980,00 (approximately US$ 48.976,20), allowing a net economy of R$1.562.390,00 (approximately US$ 2.640.439,10) per year (Barbieri, Álvares e Cajazeira, 2009).

3. Methodology

3.1 Method

The present research was performed between May 2010. It had applied nature, according Lakatos and Marconi (2006), because “characterized itself for its practice interest, namely, that the results are applied or used, immediately, in the problems solution that occur in the reality”, with qualitative approach in relation to the themes treated.

From the standpoint of the objectives, this study classifies itself as exploratory, providing more intimacy with the problem, making it more explicit, improving the ideas and discoveries of the intuition and descriptive, having the definition of the characteristics of determinate phenomena, being used techniques of data collection, such as the questionnaire and systematic observation (Gil, 1999).

In relation to the their techniques procedures as bibliographic, being used dissertations, techniques books, articles and jounals, and case study, because has the objective to achieve a wide knowledge and detailed of the theme from the profound study of one or few objects related to it (GIL, 1999 and LAKATOS and MARCONI, 2000).

The data were collected for document analysis, direct observation and previous diagnosis of the level of management in that fits to Cleaner Production and what would be the themes that could be launched in the Suggestions Program that provided benefits to the company.

3.2 Characterization of the search unit

The Suprametal industry and trade in artifacts Aluminum Ltda. is a company incubated at the Federal Technological University of Paraná, Campus Ponta Grossa, of the Casting Industry of secondary aluminum, working with zero stock (just-in-time), since the year 2006.

“The mission of the Suprametal is to provide aluminum bounding material, from the materials recycling post-consumer and post-sale, searching clean technologies in their productive processes for the achievement of products with quality and competitive prices, acting with environmental and social responsibility”.

The company owns as the main machineries electric oven to induction 100 kW and 3000 Hz, capability of 40 kg of aluminum per course or 48,5 kg/h and an optical emission spectroscopy.

The raw materials used for the manufacturing of aluminum ingots are: profiles, soft aluminum, cans, pistons, pots, headstocks, hard aluminum, cables and plates.

The residues created by the company are predominantly constituted by the slag (containing approximately 50% of aluminum in its composition), that is sold to the people who buy scrap of the region.

3.2.1 Description of productive process

Firstly the customer requests the amount and the kind of aluminum that wishes. Using a worksheet in excel makes itself the determination of the necessary amounts of each king of scrap (classified as: profiles, soft aluminum, cans, pistons, pots, headstocks, hard aluminum, cables and plates) considering the chemical composition approximated of each. Are requested types and amounts necessary to the supplier of the raw materials.

Upon receiving the material is done the weighing and storage of each type of scrap. Hereafter is done a new weighing of the materials separating them in the adequate proportions to the course and conforming them to the dimensions that enable its insertion into the oven.

Held the melting process, added the material that clears metals from the slag, removes the slag formed and is done the leakage delivery and preparation of specimen (samples).

Makes the analysis of the chemical composition of the sample in the optical emission spectroscopy, where is verified whether the chemical composition is inside the parameters required by the customer.

- If yes: to leak the material in ingots and make the dispatch of outsourced transportation to the customer.

- If not: to add the elements for the correction and come back to the procedure of leakage and preparation of specimen and finally leaks the material in ingots and procedures for the dispatch of them.